Improved cooling discharging Slapple activating furnace

A technology of Sleep activation furnace and material Sleep furnace, applied in the field of activated carbon production equipment, to solve the harsh working environment and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

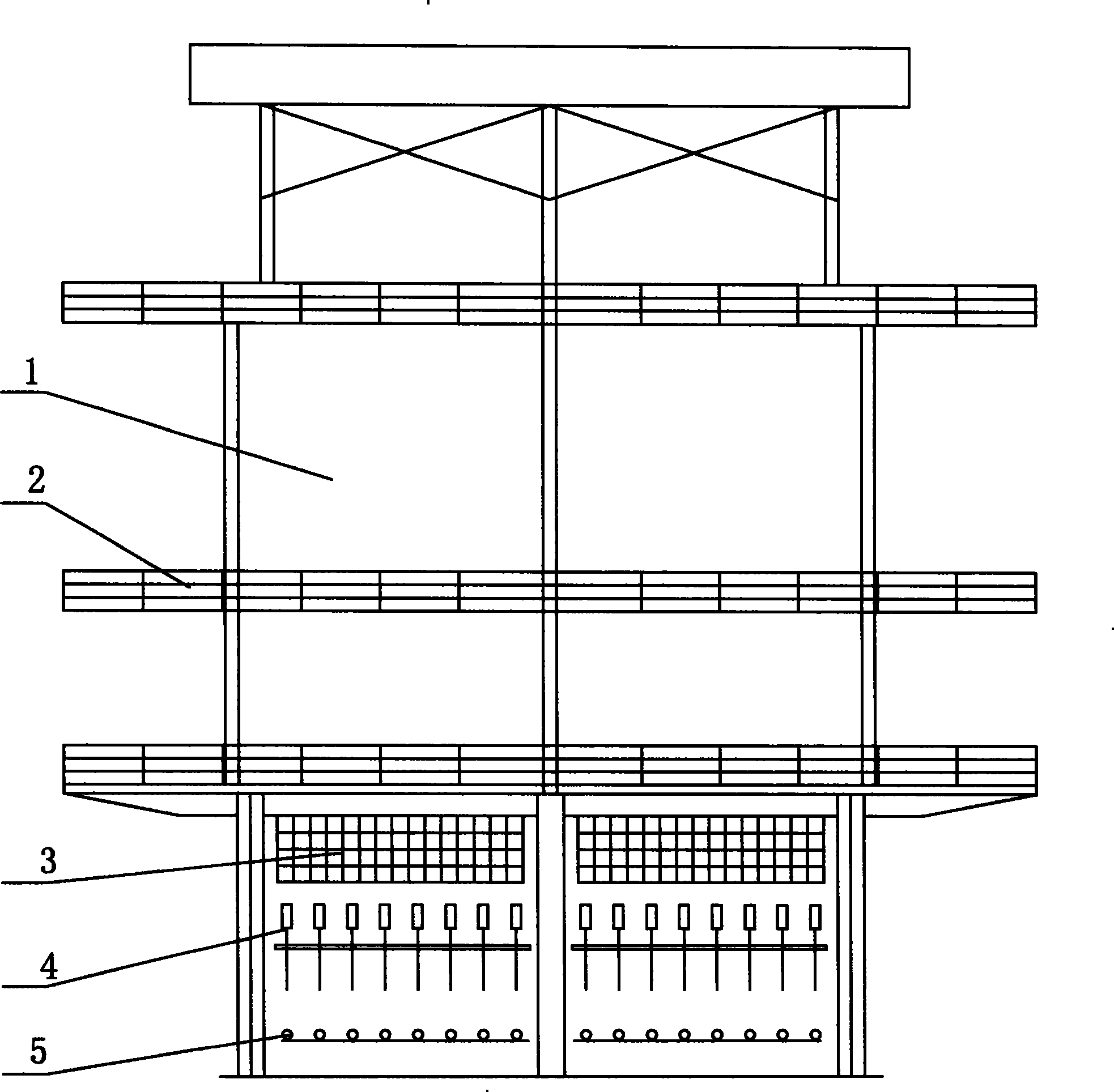

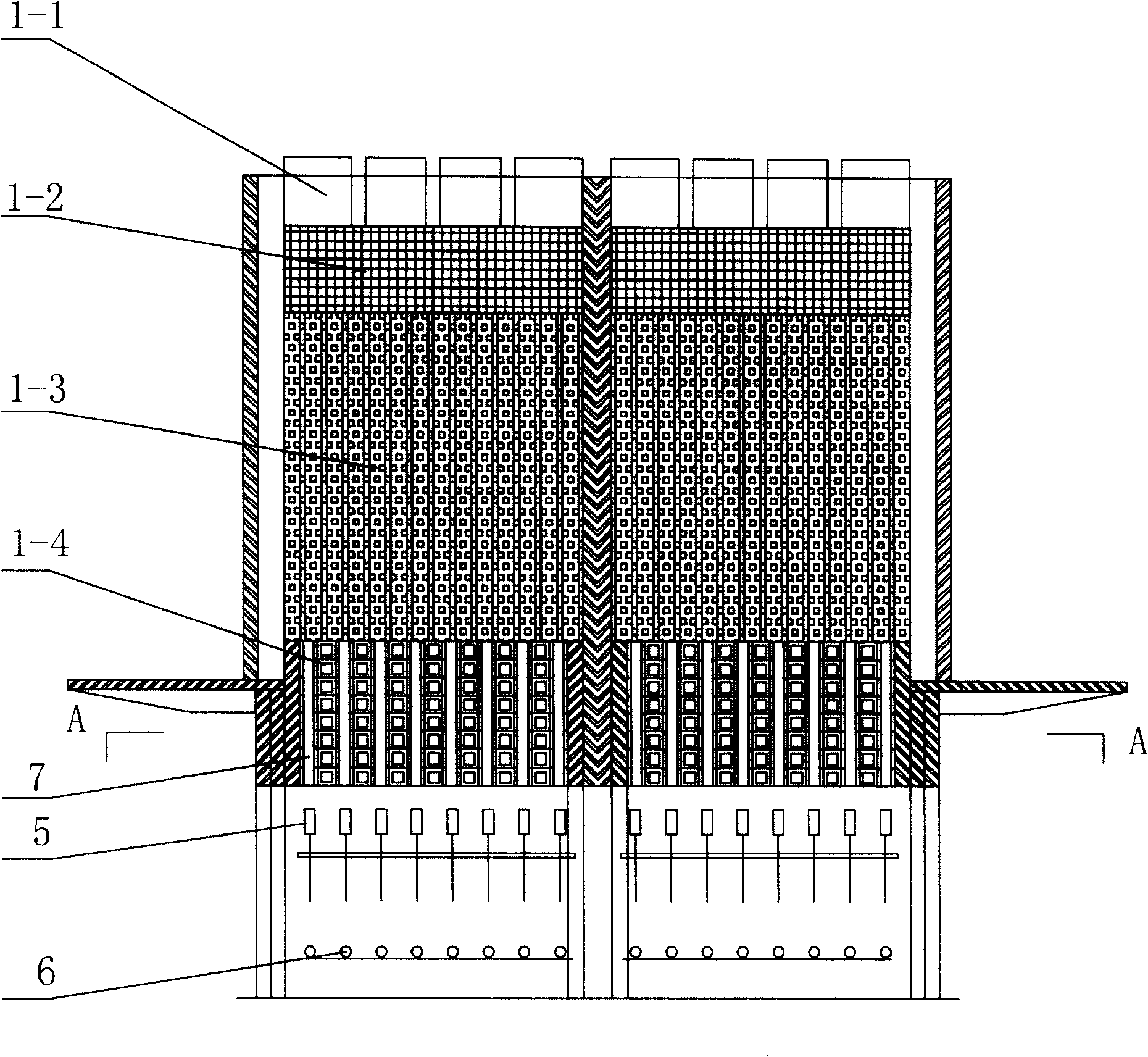

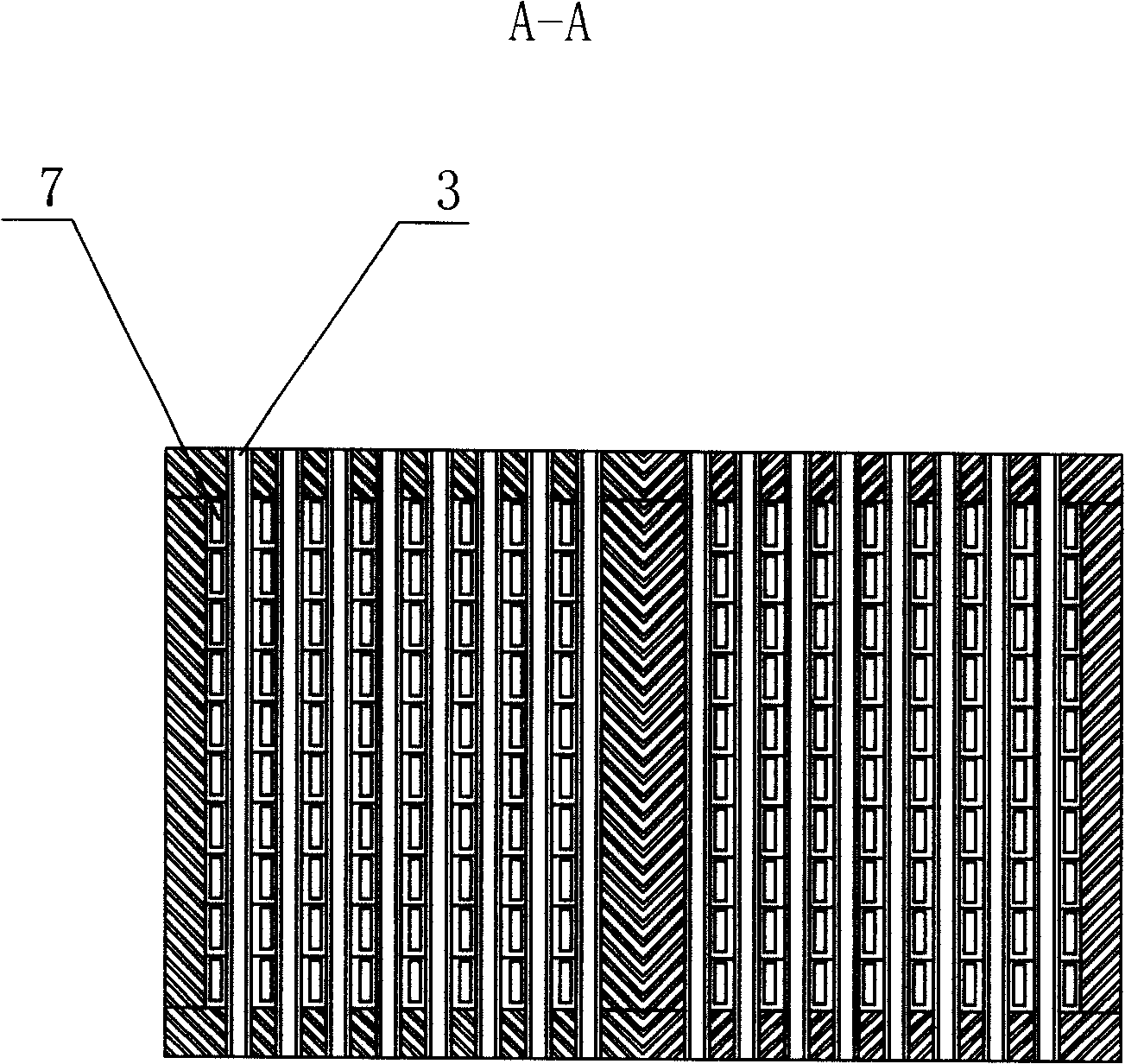

[0022] like figure 1 , figure 2 As shown, the main body of the present invention is similar to the conventional Sleep furnace, including an activation furnace body (1) and a regenerator (not shown in the figure), an operation platform (2) is arranged outside the activation furnace body, and the furnace body is from top to bottom They are feed inlet (1-1), carbonization section (1-2), activation section (1-3), cooling zone (1-4). Below the cooling zone is the discharge device (4) and its load beam, the bottom Discharge port (5) is arranged; The improved part of the present invention is as image 3 , Figure 4 As shown, the channel (3) passing through the front and back in the cooling zone is partly or completely communicated with the outside world, and the number 7 in the figure is the channel of the material in the activation zone.

[0023] If the ambient temperature is too high, an air collecting hood can be added on the side of the cooling belt, and the air collecting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com