Electrostatic chuck device

An electrostatic chuck, electrostatic adsorption technology, applied in the application of electrostatic attraction holding devices, circuits, electrical components, etc., can solve the problem of difficulty in manufacturing large-sized electrostatic chucks, high prices, and reduce the operation rate and equipment. There are several, the effect of preventing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

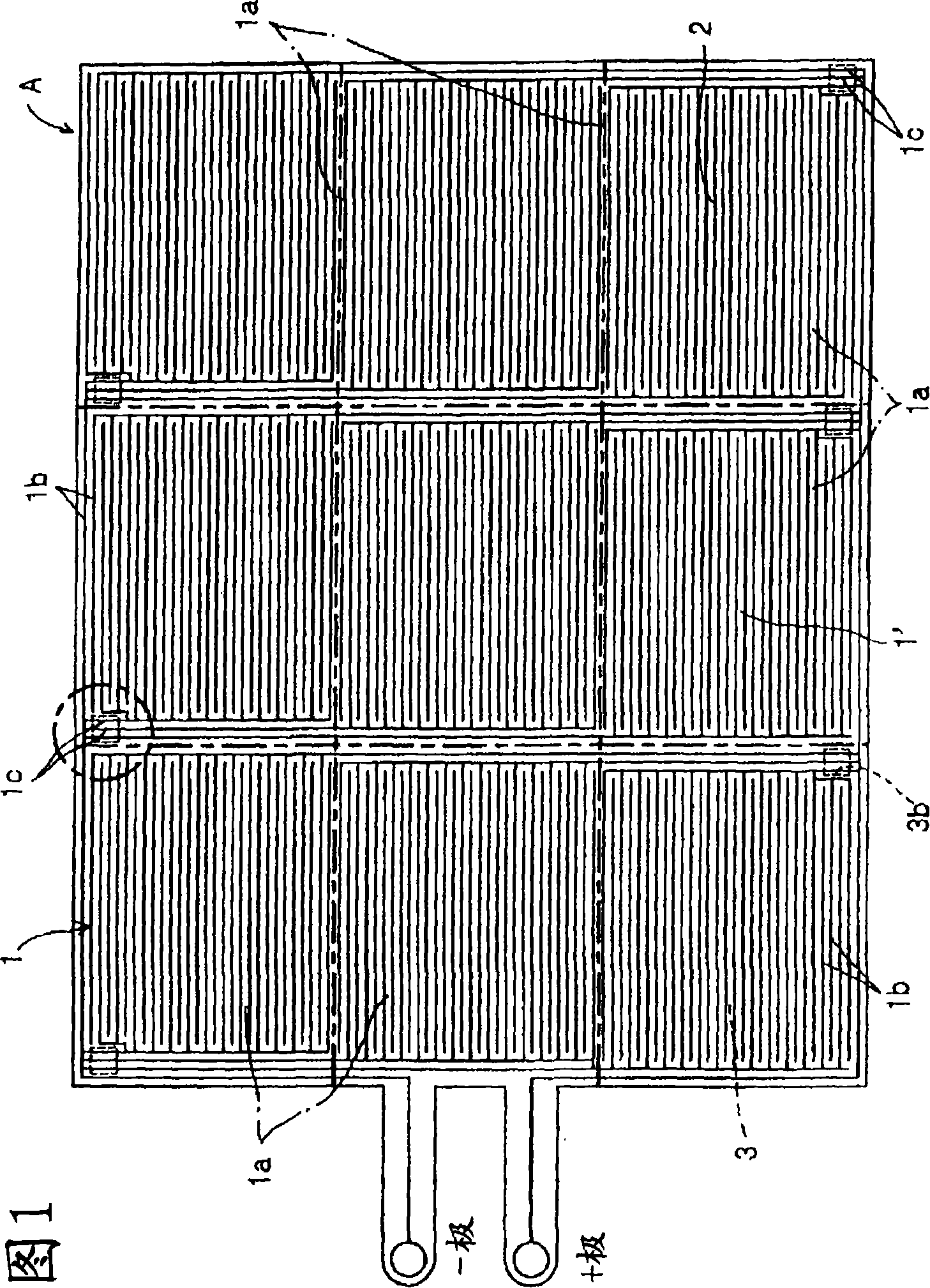

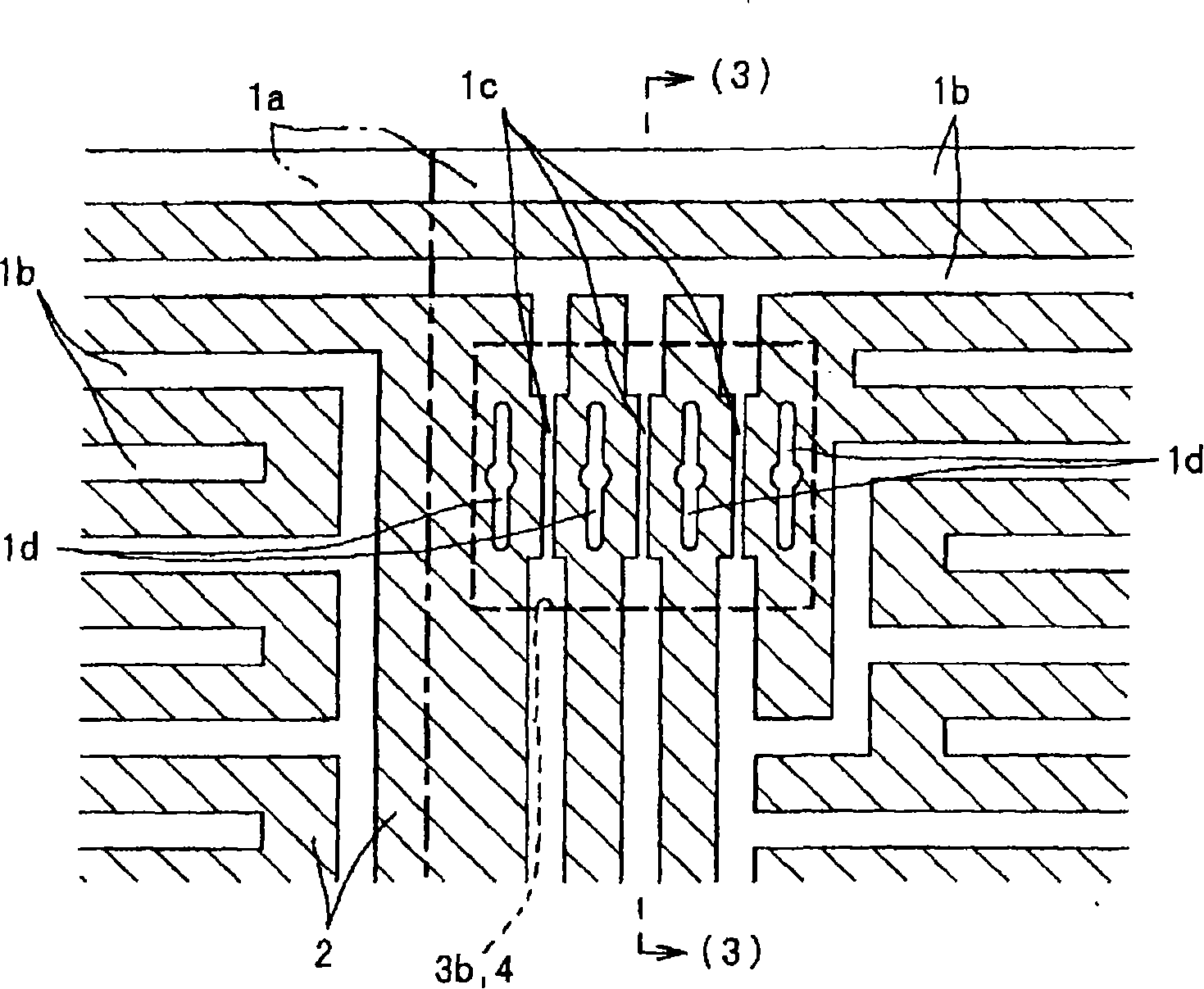

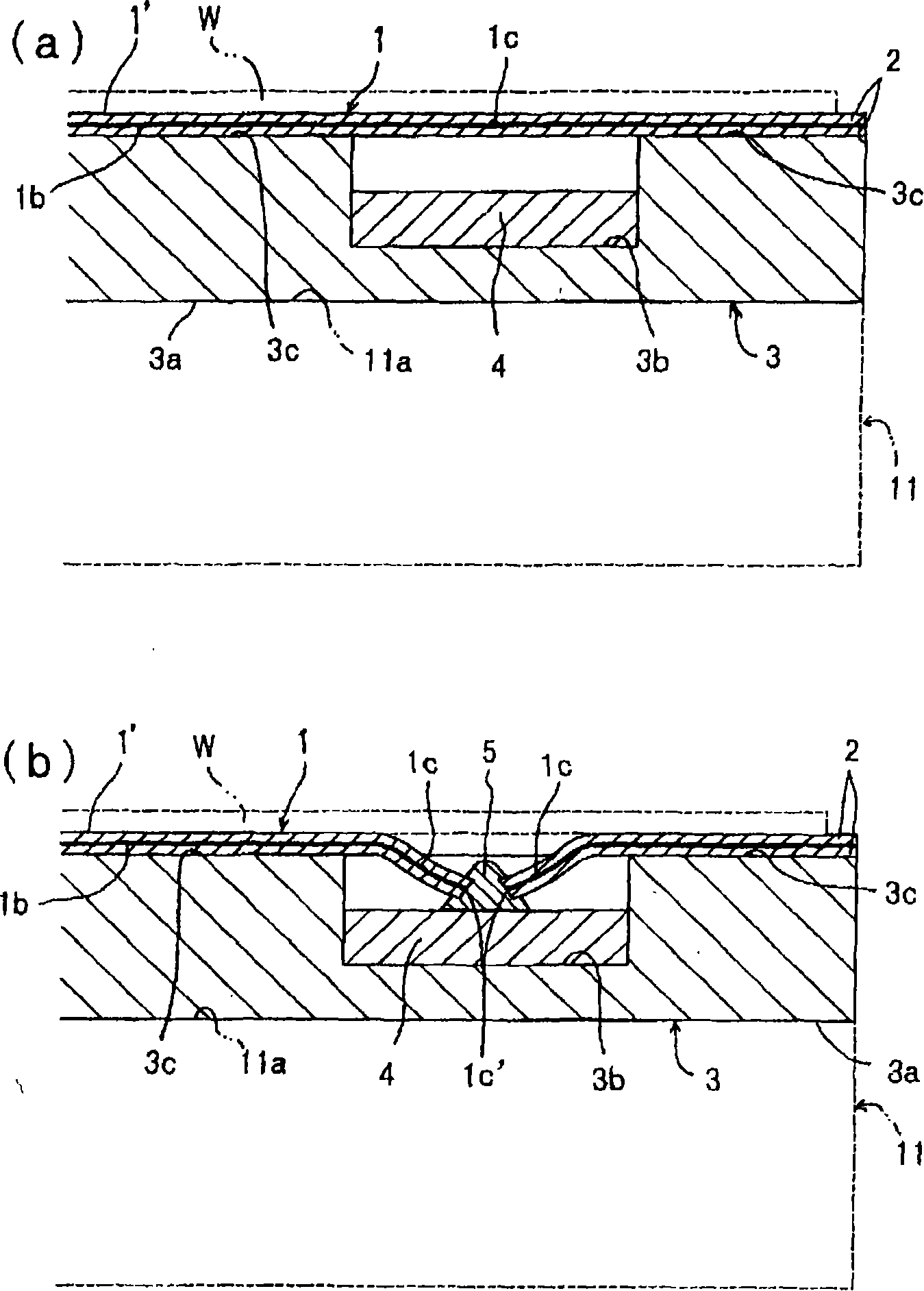

[0072] Figure 1~ image 3 As shown, this embodiment 1 shows that the above-mentioned electrode pattern 1b is a bipolar electrostatic chuck with a + pole electrode and a - pole electrode, and these + pole and - pole electrode patterns 1b are inserted and sealed in a polyimide Among the dielectric layers 2 made of engineering plastics such as amine or polyetheretherketone (PEEK), at the same time, the above-mentioned multiple power supply parts 1c are dispersed and arranged on the inner area of the electrostatic chuck function surface 1', thereby forming an electrostatic chuck with an integrated structure. The chuck film is bonded to the metal pedestal 3, and the concave portion 3b is formed on the surface 3c of the pedestal 3 so as to face the above-mentioned power supply part 1c.

[0073] In the illustrated example, the above-mentioned area 1a has a rectangular shape, and the + pole and - pole of the above-mentioned electrode pattern 1b are respectively formed in the shape o...

Embodiment 2

[0089] This embodiment 2, as shown in Fig. 4~ Figure 5 As shown, the above-mentioned plurality of power supply parts 1c are scattered and arranged in the outer area of the electrostatic chuck function surface 1' facing the workpiece W and provided with the electrode pattern 1b, thereby forming an electrostatic chuck film with a bendable integral structure, And these outwardly protruding power supply parts 1c are bent and fixed along the side surfaces 3d of the pedestal 3, or are bent and fixed by bonding so as to reach the back surface 3a of the pedestal 3, and on the side surfaces 3d of the pedestal 3 Or form the concave portion 3b on the back surface 3a, so that the structure of the cut part 1c' of the cut power supply part 1c is sealed, which is different from the above-mentioned Figs. image 3 Shown embodiment 1, the structure outside it and Fig. 1~ image 3 Example 1 shown is the same.

[0090] Therefore, in Figure 4- Figure 5 In the illustrated embodiment 2, the s...

Embodiment 3

[0094] The structure of this embodiment 3, such as Figure 6 ~ Figure 7 As shown, for the bendable electrostatic chuck film in which the above-mentioned plurality of power supply parts 1c are distributed and arranged in the outer region of the electrostatic chuck function surface 1', these power supply parts 1c are bent along the side 3d or the back surface 3a of the pedestal 3 And it is fixed by bonding, and the concave portion 3b formed opposite to the above-mentioned power supply unit 1c on the side 3d or the back surface 3a is formed into a sealed structure that can be opened and closed, and the cut power supply unit 1c is placed inside it. The cut-off part 1c' is sealed, which is different from the above-mentioned Fig. 1- image 3 The embodiment 1 shown and Fig. 4~ Figure 5 Shown embodiment 2, the composition outside it and in Fig. 1~ image 3 shown in Example 1 and in Figures 4- Figure 5 Example 2 shown is the same.

[0095] In the illustrated example, the pedestal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com