Method for producing a tubular flat knit fabric with the plating technique

A knitted fabric and cylinder technology, which is applied in the field of making circular knitted fabrics, can solve the problems of shrinking edge loops and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

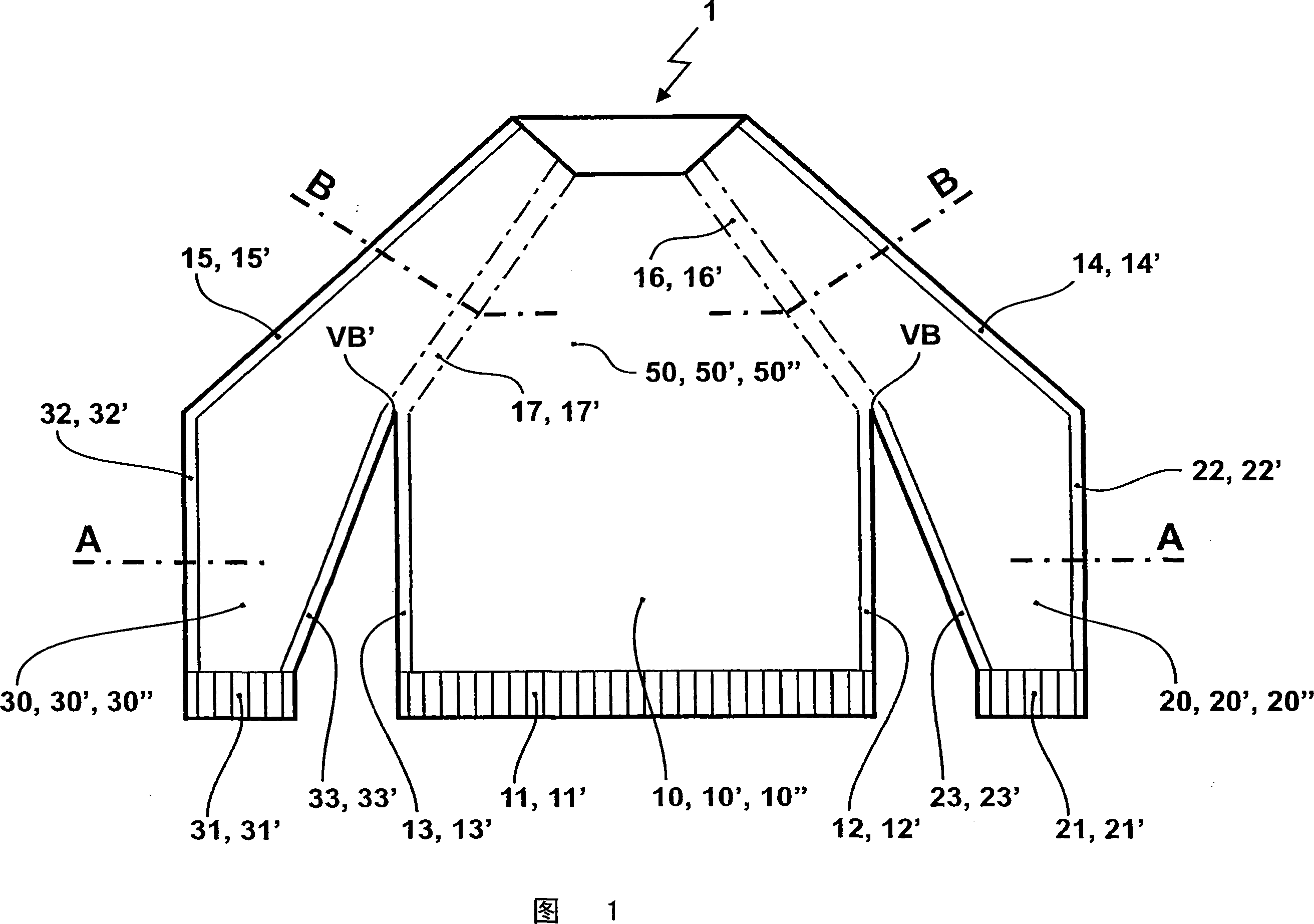

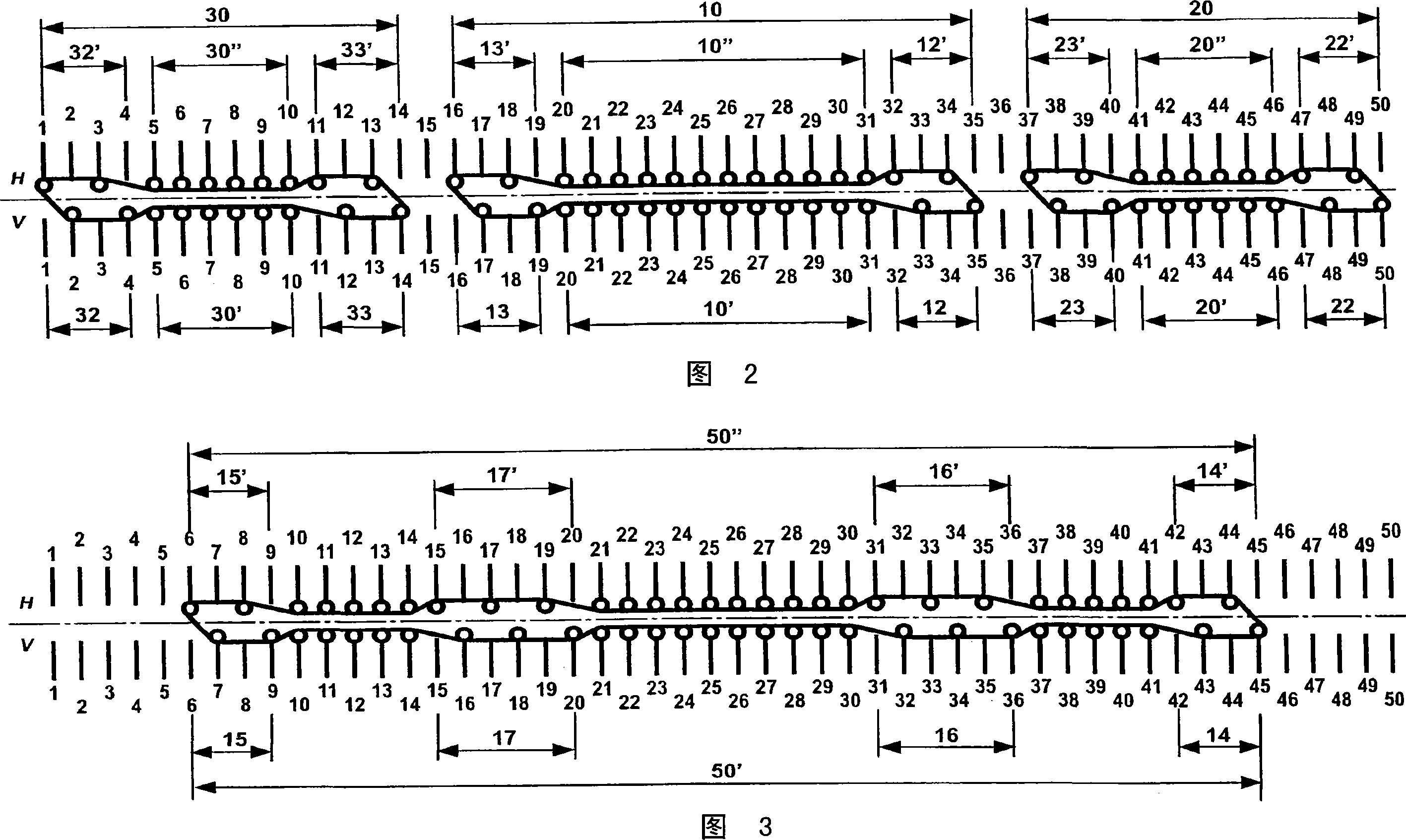

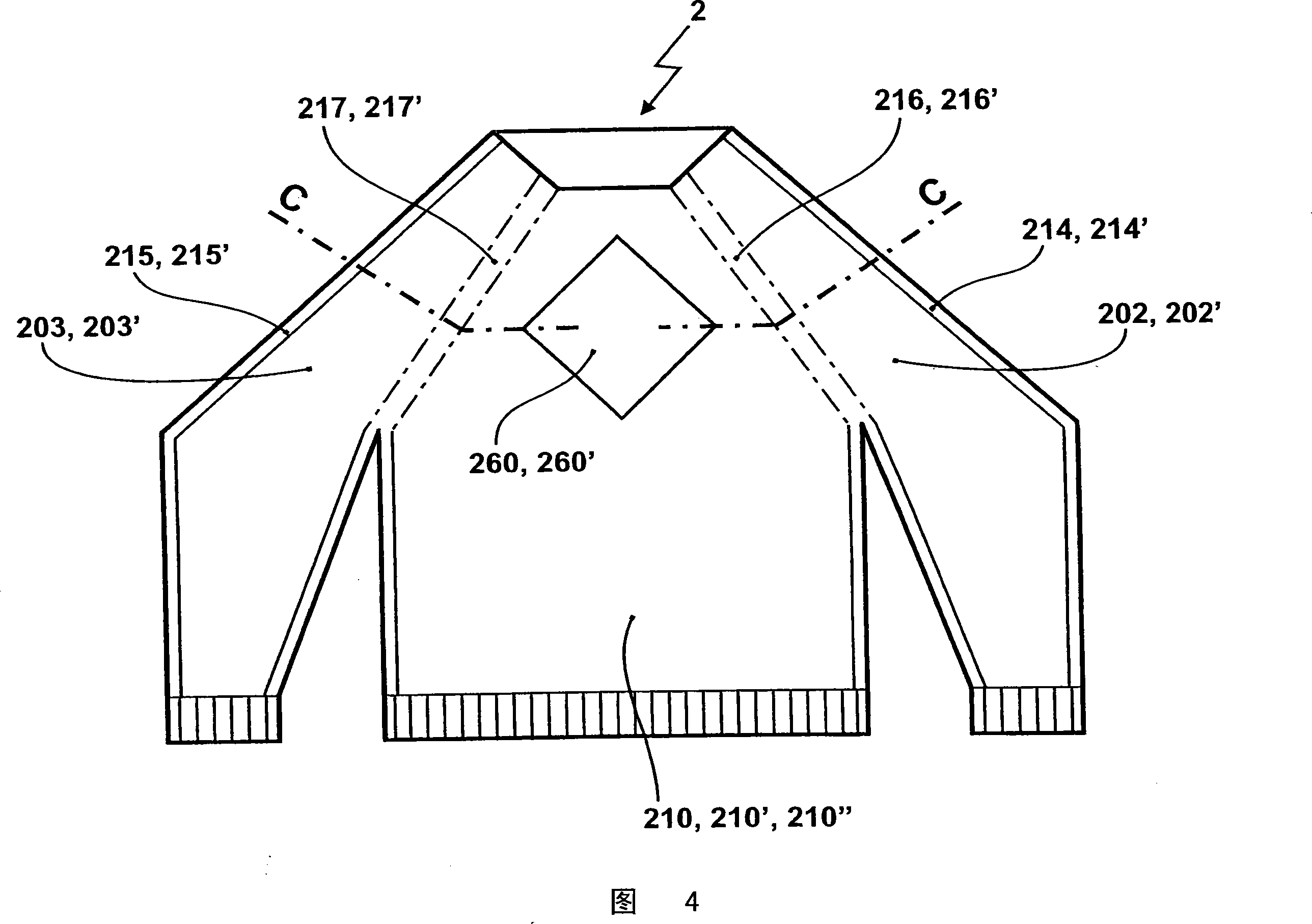

[0018] Fig. 1 shows a pullover formed as a tubular formed product knit, which can be integrally formed on a flat knitting machine. The pullover 1 is made using the plating technique, ie, to make the pullover 1 at least two different knitting threads are supplied to each needle involved in the knitting process in order to form loops.

[0019] The sequence of the knitting sequence to form the tubular former knitted fabric 1 is consistent with the prior art. It starts with three separate circular knits, a body part 10 , a left sleeve 20 and a right sleeve 30 . Each of the three tubes 10, 20, 30 is supplied with knitting thread via a separate thread guide. Then, from the connecting regions VB, VB' where the left sleeve 20 and the right sleeve 30 are sewn to the body part 10, the knitted fabric is formed into a single circular knitted fabric 50. In this area, the knitting thread is generally supplied by a yarn feeder.

[0020] In the example shown, ribbing is located at the unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com