Method for filling micropores by utilizing tin whisker growth

A tin whisker and blind hole technology, applied in the field of microelectronics manufacturing and packaging, can solve problems such as filling holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

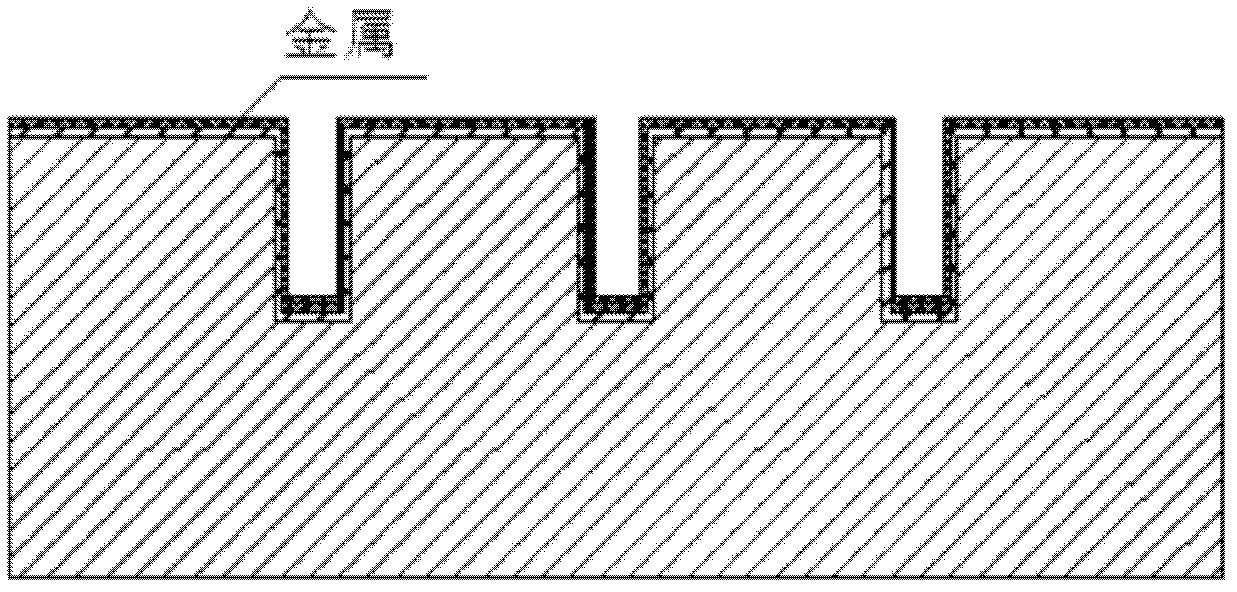

[0038] Tin whisker is a single whisker that grows spontaneously on the surface of tin-containing coatings. Tin whiskers grow at different rates at different temperatures. Experiments have shown that when the current density increases to 10 4 A / cm 2 Electromigration will occur when electromigration occurs, and the accumulation of atoms near the anode increases the internal compressive stress of the tin coating and accelerates the growth of tin whiskers. Experiments have found that this phenomenon also exists for metals such as Cd, Zn, Al, and Ag. Based on this finding, the present invention attempts to use electromigration to accelerate whisker growth to fill micropores.

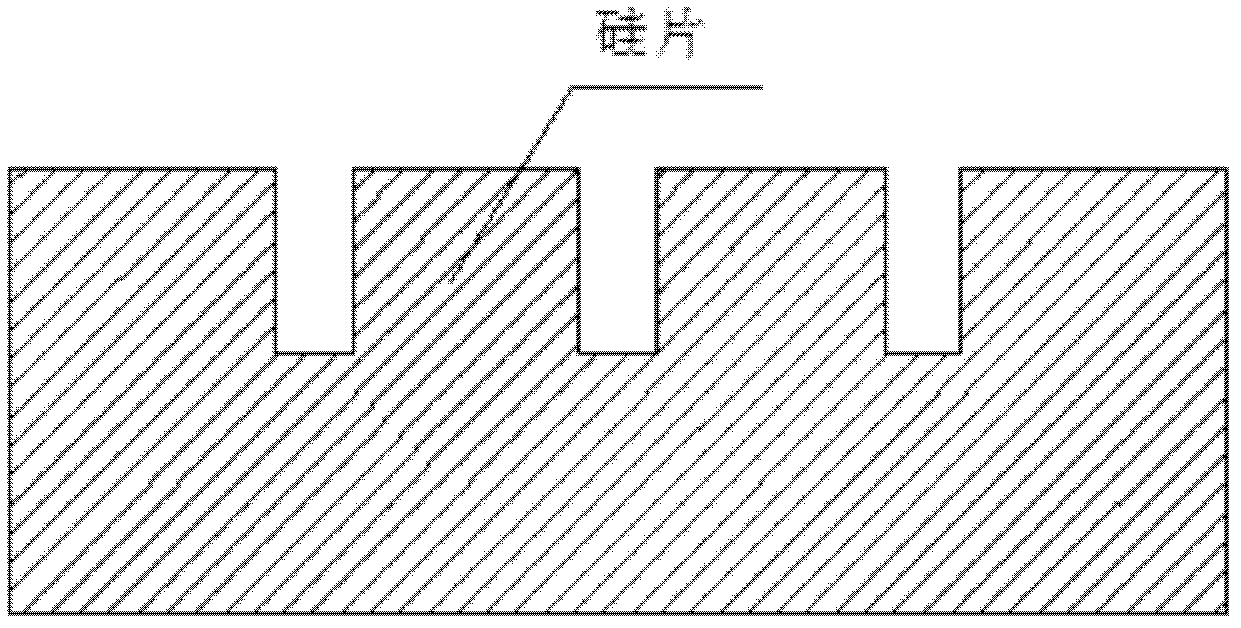

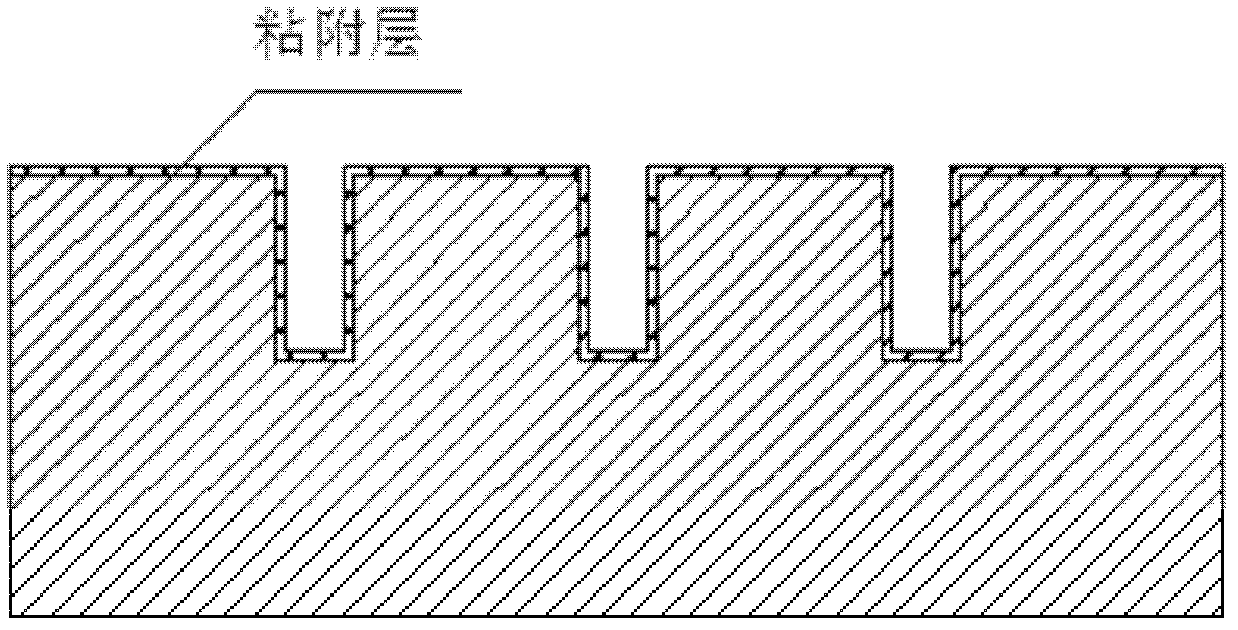

[0039] A method for filling blind vias with tin whisker growth, comprising the steps of:

[0040] (1) sequentially process the surface with blind holes on the substrate to deposit an adhesion l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com