Sling device for a piece with force compensation and hoisting system comprising the same

A hoisting device and force technology, applied in the field of lifting systems, can solve problems such as unsatisfactory, system complexity, and large instantaneous electric power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

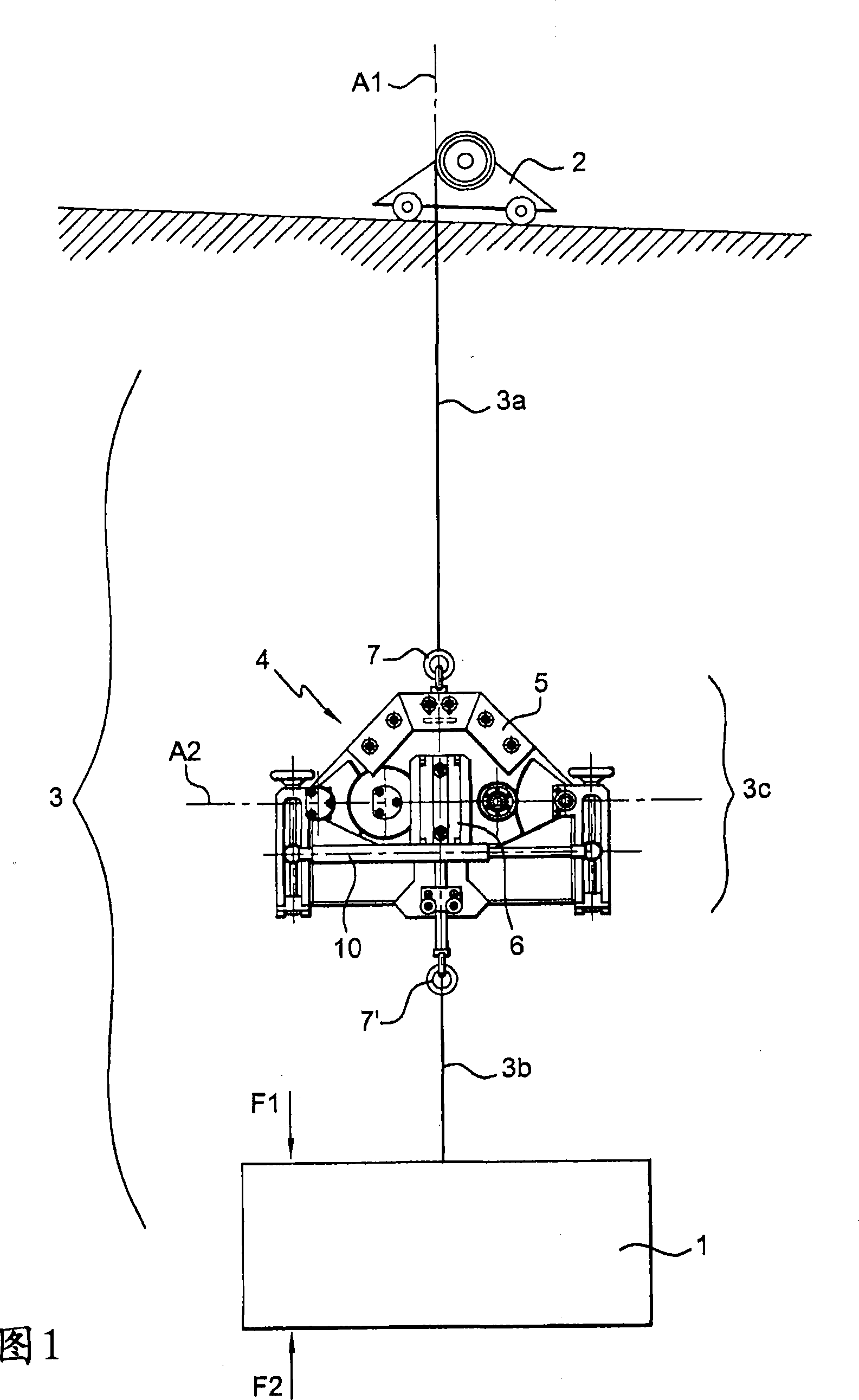

[0030] [30] The hoisting device shown in FIG. 1 has a winch 2 that moves on a guide rail and supports a member 1 held by a sling 3 .

[0031] [31] The winch moves on guide rails according to a control device not shown because it is customary. Likewise, the slings can be shortened or extended by winches in order to position the held member opposite a ground structure on which the held member has to be fitted.

[0032] [32] In fact, the winch can be replaced by any lifting device that utilizes a sling to lift the load.

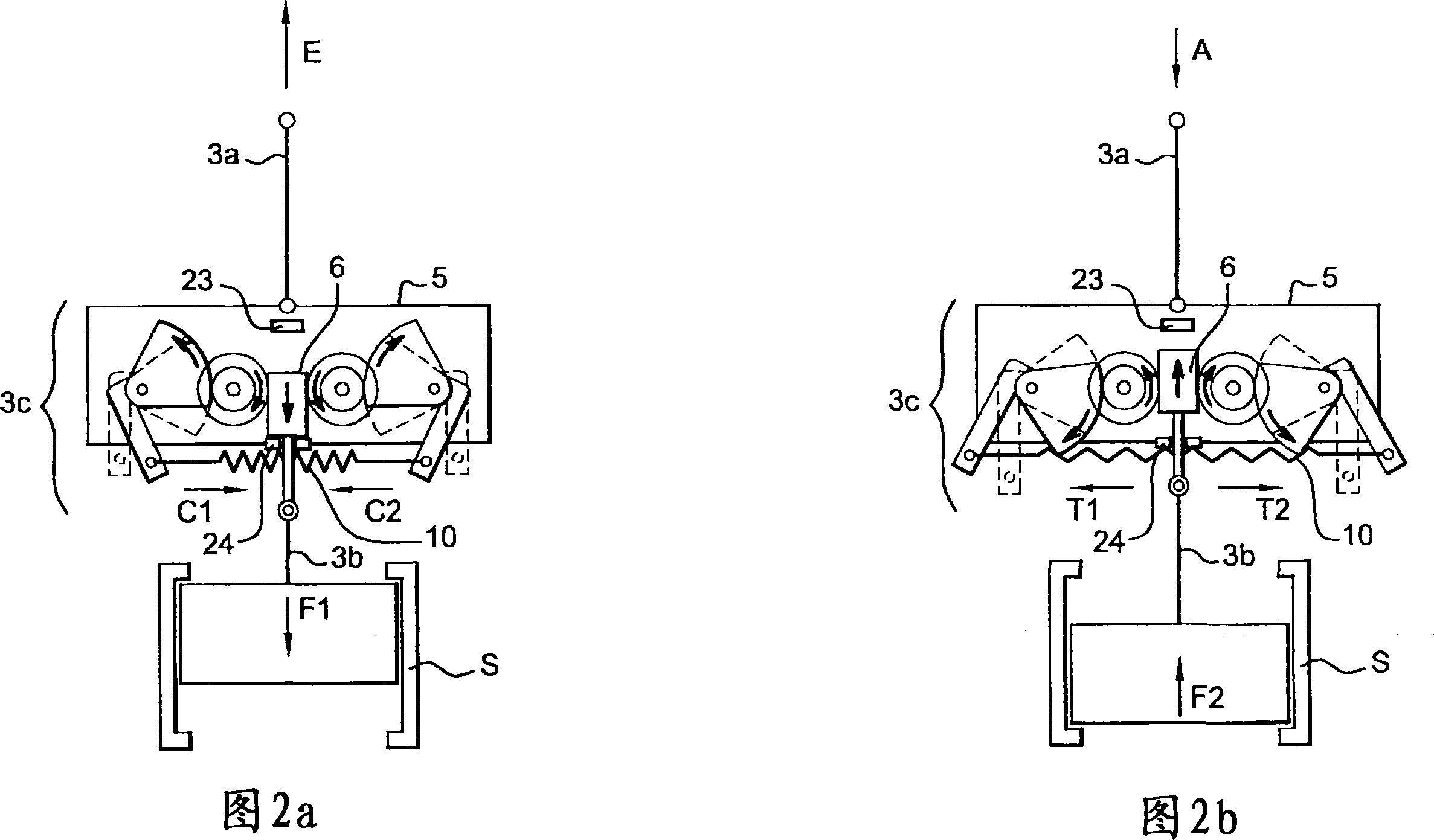

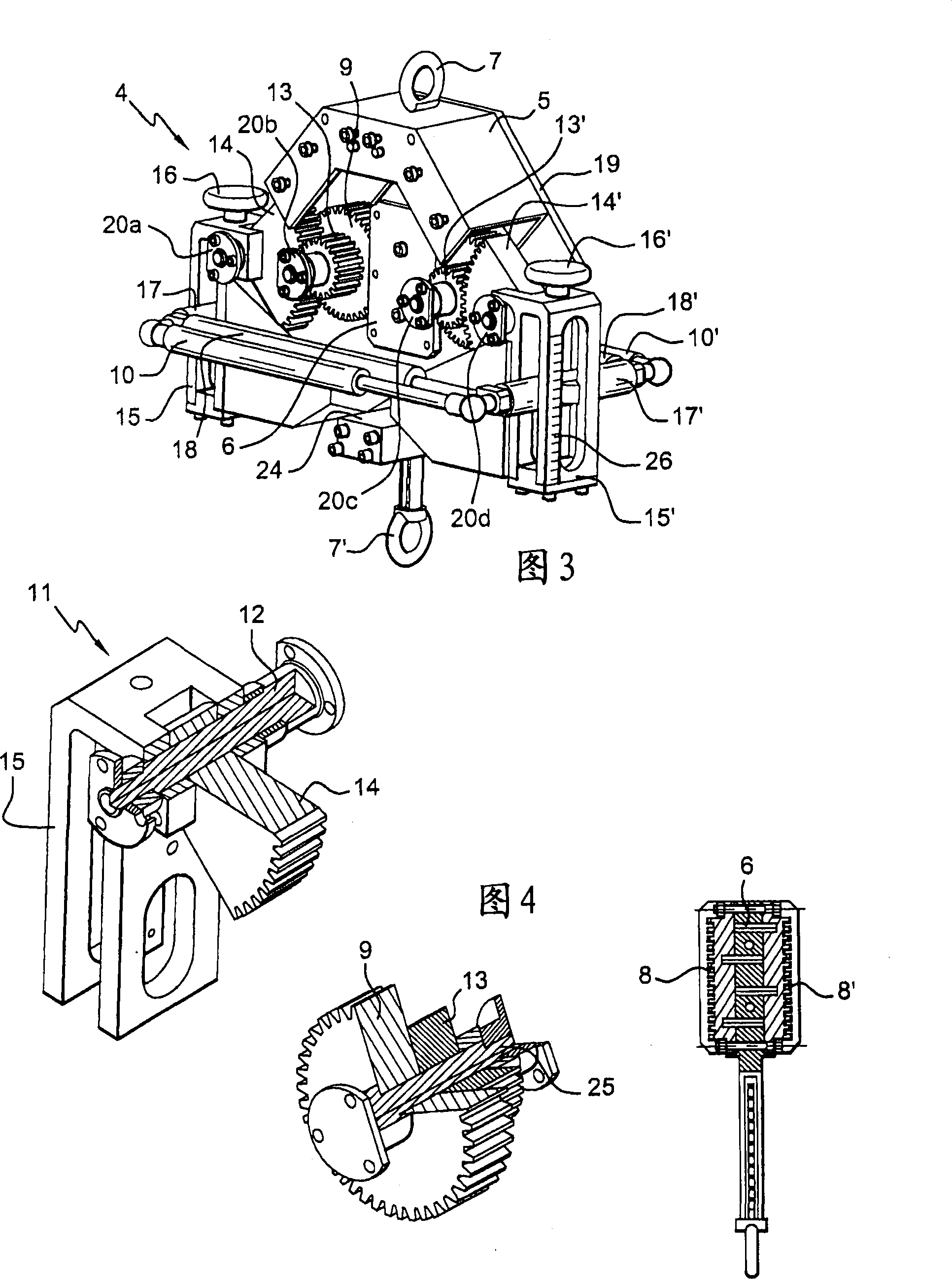

[0033] [33] According to the invention, the sling 3 is provided with a first inextensible portion 3a, which rests on a section 3c provided with spring elements 10, 10' which, under load, can For a limited variation of the load on the member 1, said spring members 10, 10' allow a limited range of elastic elongation or shortening of said sling 3. The sling according to the shown embodiment is also provided with a second inextensible portion 3b, which is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com