Ink feed control method and ink feed control system

A control method and technology of a control device, which are applied in the field of control of calling ink and control device for calling ink, can solve the problems of high concentration of printed matter and inability to print printed matter, reduce adjustment time, increase output, and be beneficial to the environment. protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

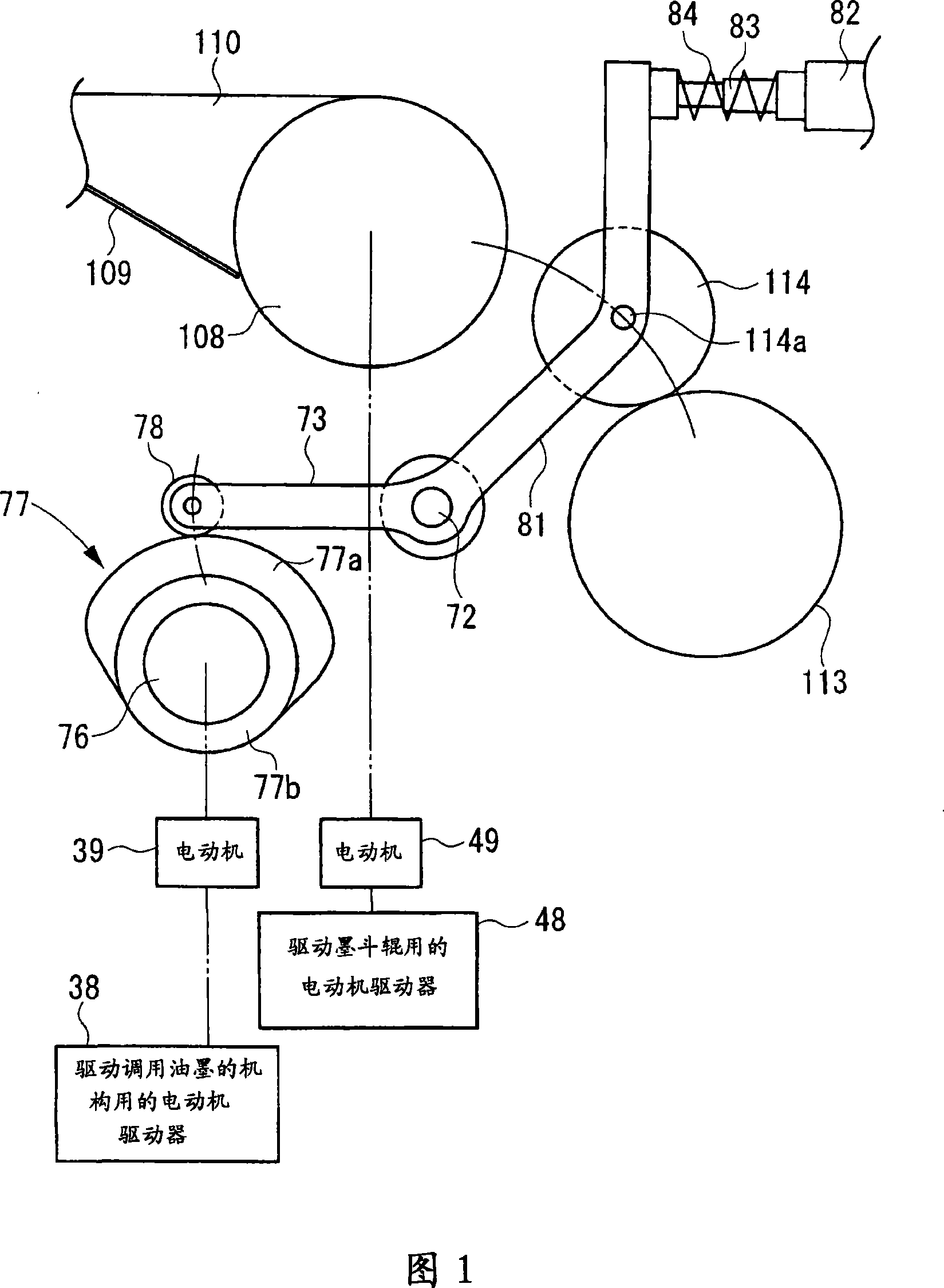

[0115] First, the configuration of the ink dispensing control device according to the first embodiment of the present invention will be described. Fig. 1 is a side view showing main parts of an ink unit of a printing machine according to a first embodiment of the present invention. In this figure, the same or equivalent components as those of the prior art in FIG. 48 described above are assigned the same reference numerals, and detailed description thereof will be omitted. Between the ink fountain roller 108 as the roller on the upstream side of the ink transfer direction and the agitating roller 113 as the roller on the downstream side of the ink transfer direction, the transfer roller 114 and the transfer shaft 72 that becomes the swing fulcrum for swinging are supported on the left and right sides. On the right frame (not shown in the figure), it can rotate freely. An axle end of this calling shaft 72 protrudes from the frame, and a cam lever 73 is provided on this protrud...

no. 2 approach

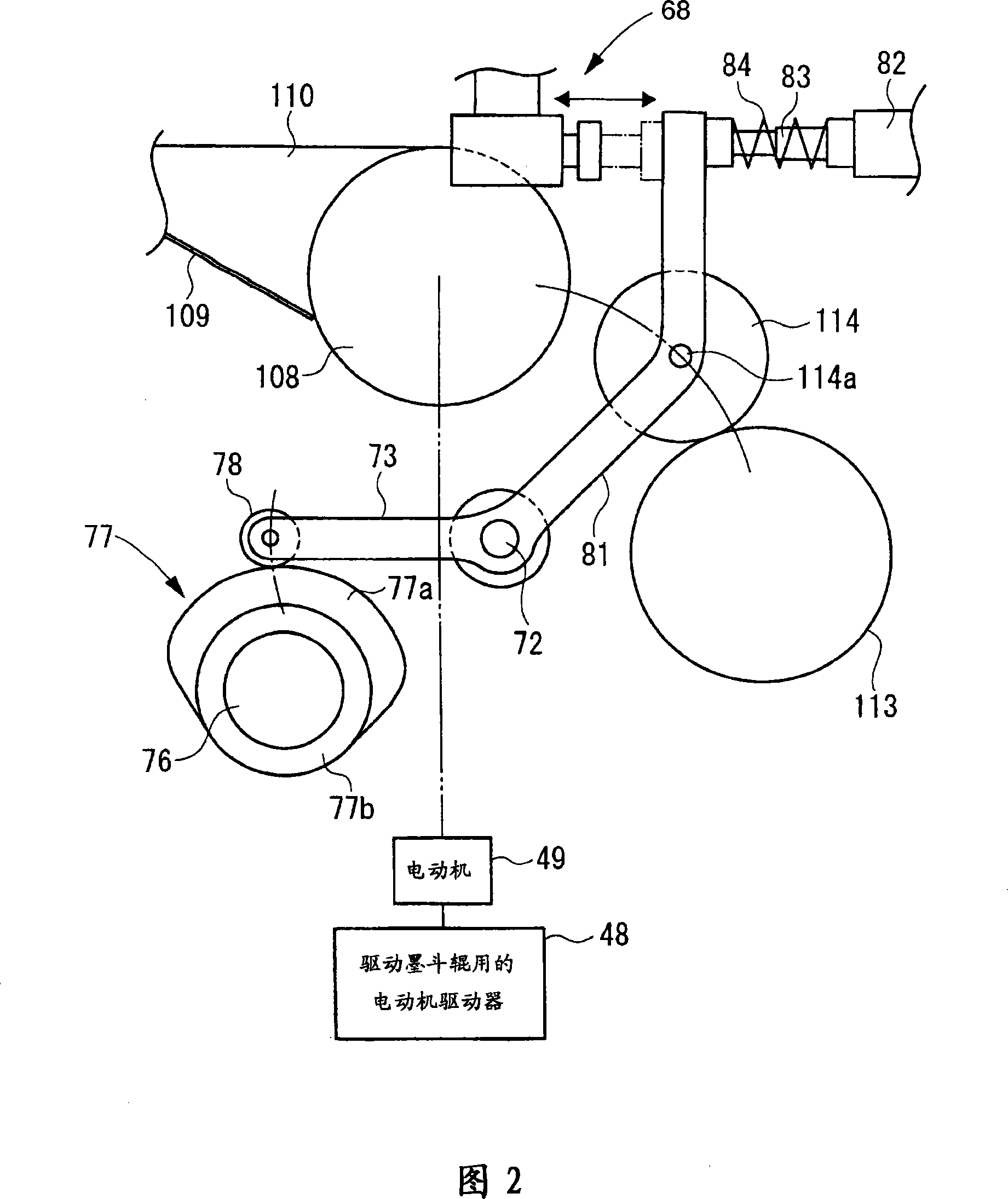

[0271]First, the configuration of an ink calling control device according to a second embodiment of the present invention will be described. Fig. 2 is a side view showing a main part of an ink unit of a printing machine according to a second embodiment of the present invention. In this figure, the same or equivalent components as those of the prior art in FIG. 48 described above are assigned the same reference numerals, and detailed description thereof will be omitted. In addition, in the second embodiment of the present invention, the basic drive of the ink dispensing mechanism is performed using the cam 77 and the like, but since the structure is the same as that of the first embodiment, description thereof will be omitted. In addition, the cam 77 is driven by the drive motor of the printing press. Between the ink fountain roller 108 as the roller on the upstream side of the ink transfer direction and the agitating roller 113 as the roller on the downstream side of the ink ...

no. 3 approach

[0418]First, the configuration of an ink dispensing control device according to a third embodiment of the present invention will be described. Fig. 2 is a side view showing main parts of an ink unit of a printing machine according to a third embodiment of the present invention. In this figure, the same or equivalent components as those of the prior art in FIG. 48 described above are assigned the same reference numerals, and detailed description thereof will be omitted. In addition, in the third embodiment of the present invention, the basic drive of the ink dispensing mechanism is performed using the cam 77 and the like, but since the structure is the same as that of the first embodiment, description thereof will be omitted. In addition, the cam 77 is driven by the drive motor of the printing press. Between the ink fountain roller 108, which is a roller on the upstream side in the ink transfer direction, and the stirring roller 113, which is a roller on the downstream side in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com