Unit type high-strength elastic packing smell-less biological turnplate

A biological turntable, elastic filler technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of improved processing efficiency, easy installation and maintenance, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

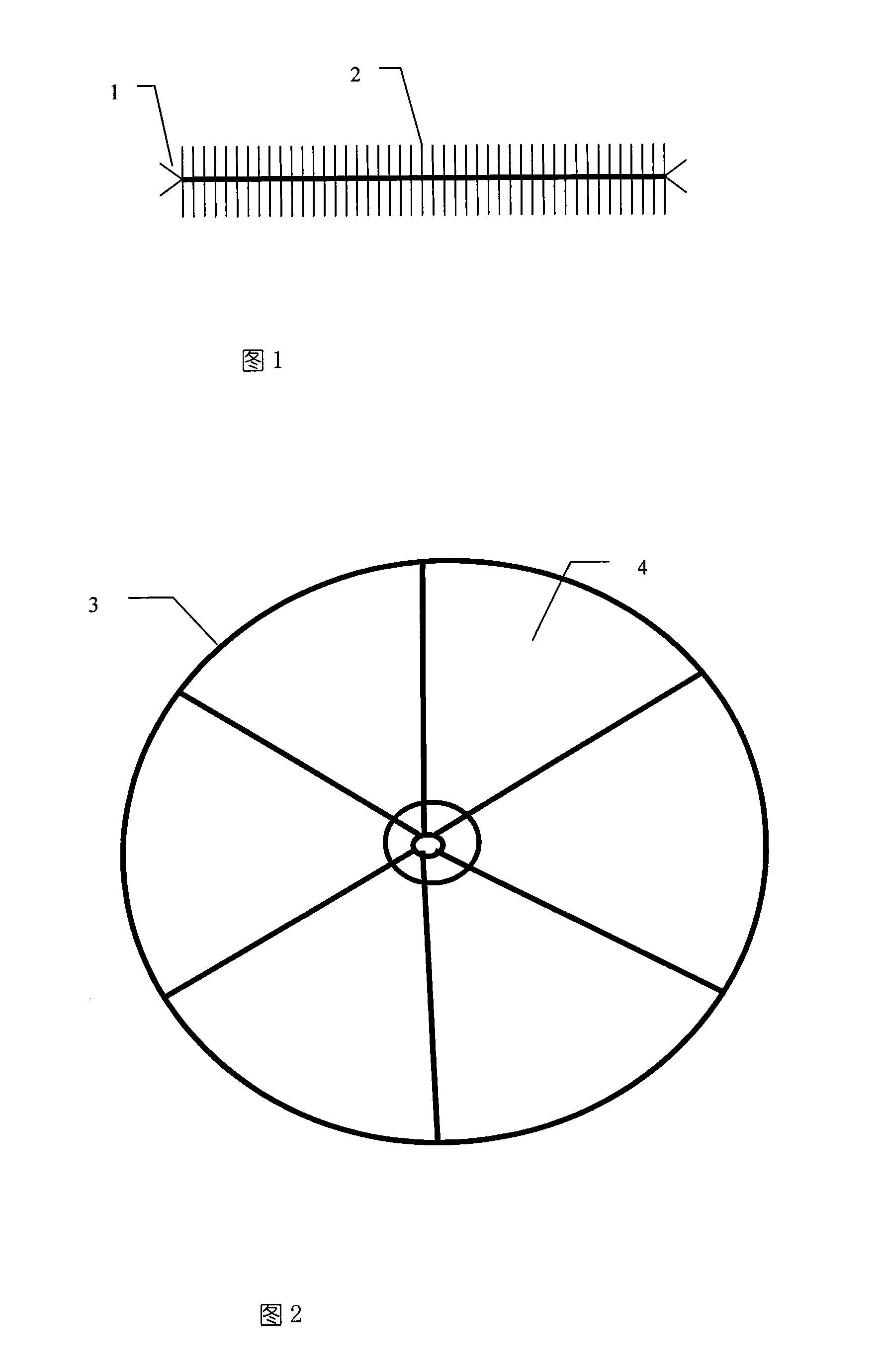

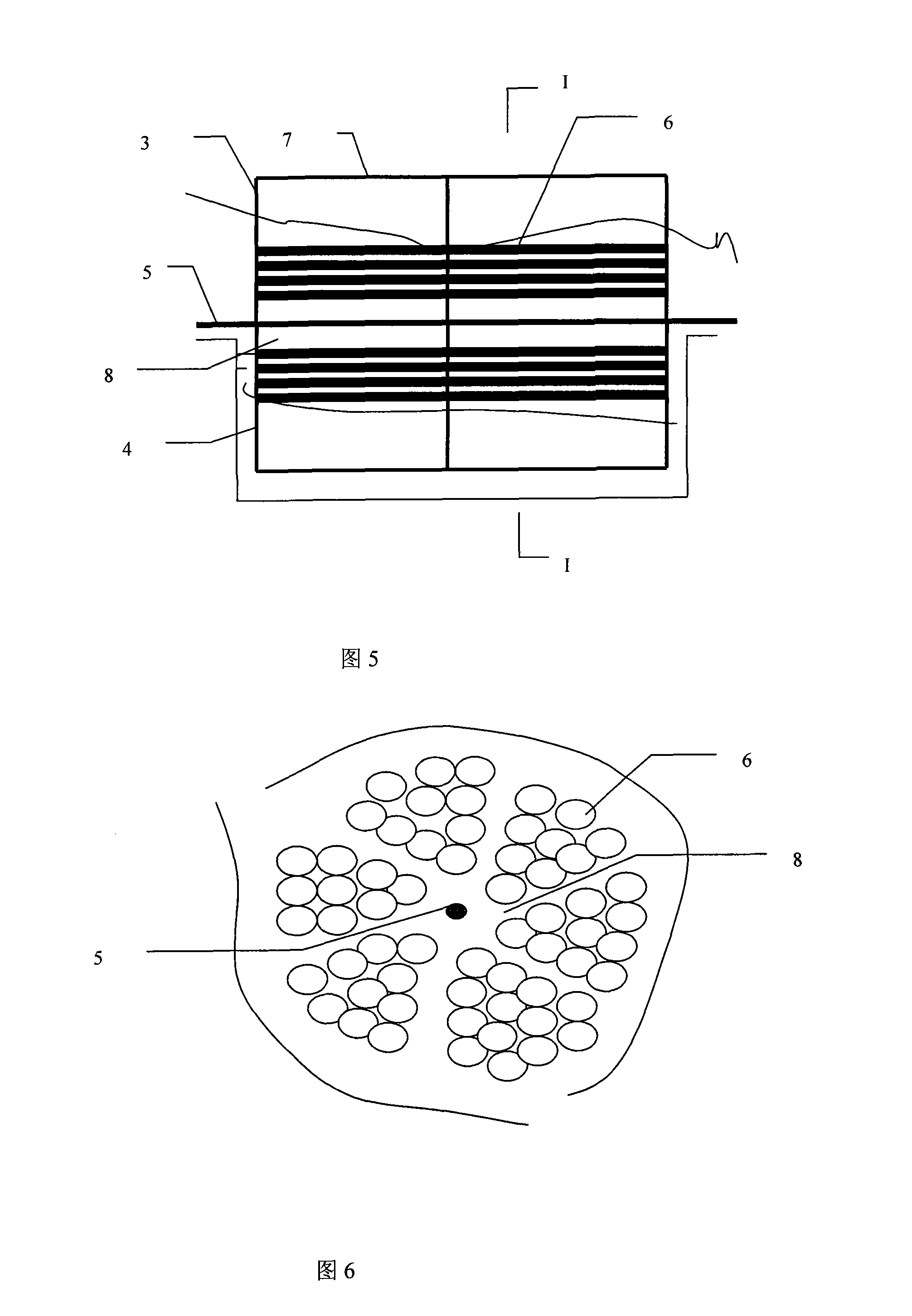

[0028] In Fig. 1, a high-strength elastic filler (7) is formed by twisting two strands of iron wire (1) covered with single-layer plastic wire (2). In order to ensure sufficient strength and service life, the iron wire usually adopts ordinary iron wire or stainless steel wire with a surface treatment of ≥2.8mm. In order to ensure that the plastic wire has a certain strength and there is a certain gap between the plastic wires, a PP plastic wire with a length of 0.7-0.9mm and a length of about 12cm is generally used. After being made, the filler is 0.8-1.0m long and 12cm long.

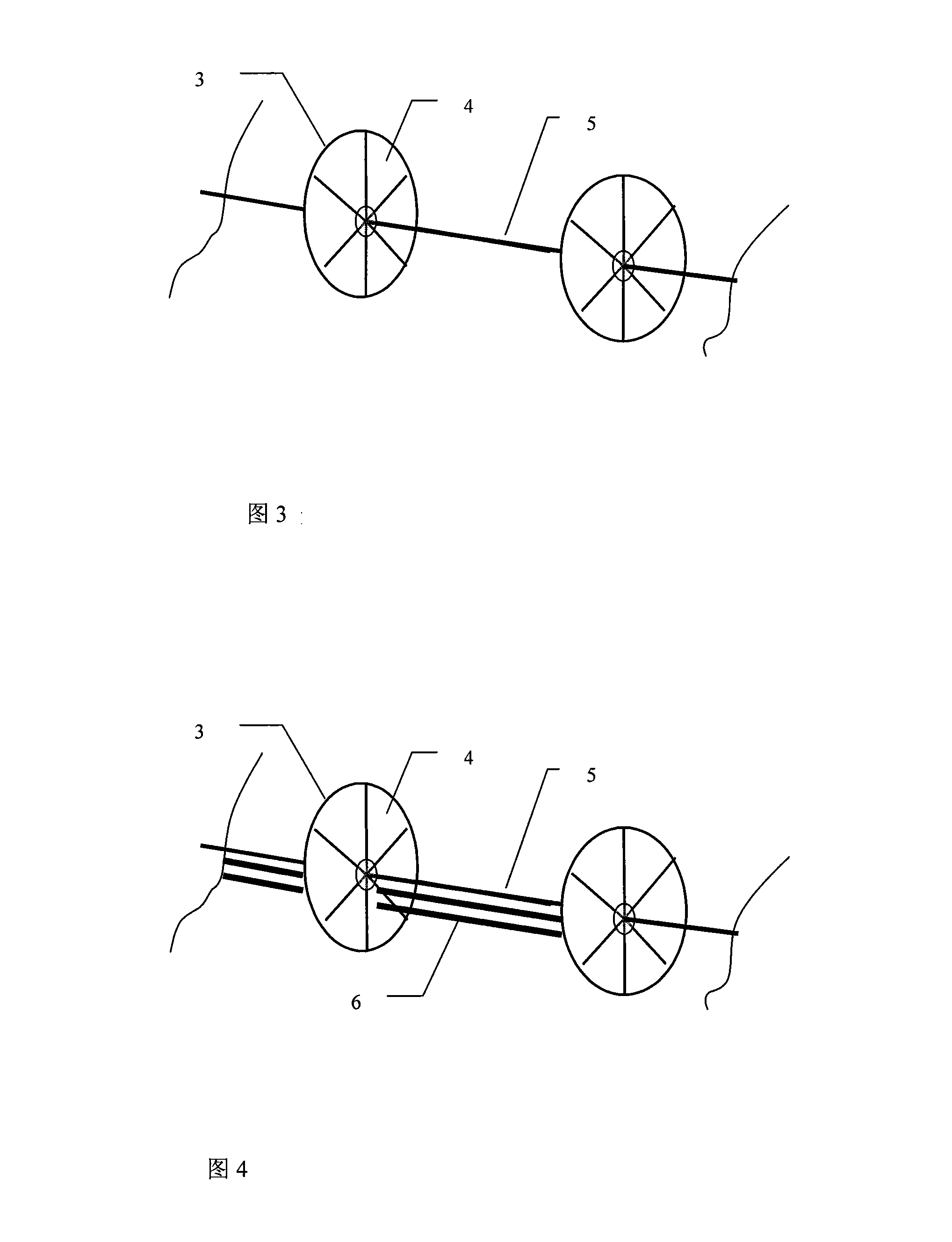

[0029] In Fig. 2, the circular frame (3) is welded by angle steel or stainless steel, and then the dividing plate (4) is installed on the steel frame. The partition is a thin steel plate of 2-4mm, welded to the steel frame, and then drill a 7-8mm round hole for packing at the designed position. If ordinary angle steel or steel plate is used, derusting and anti-corrosion treatment should be carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap