Self-temperature controlled valve

A technology of self-operated temperature control valve and valve cover, which is applied in the direction of lifting valve, valve details, valve device, etc., and can solve the problems of wear gap, water leakage, heat medium leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

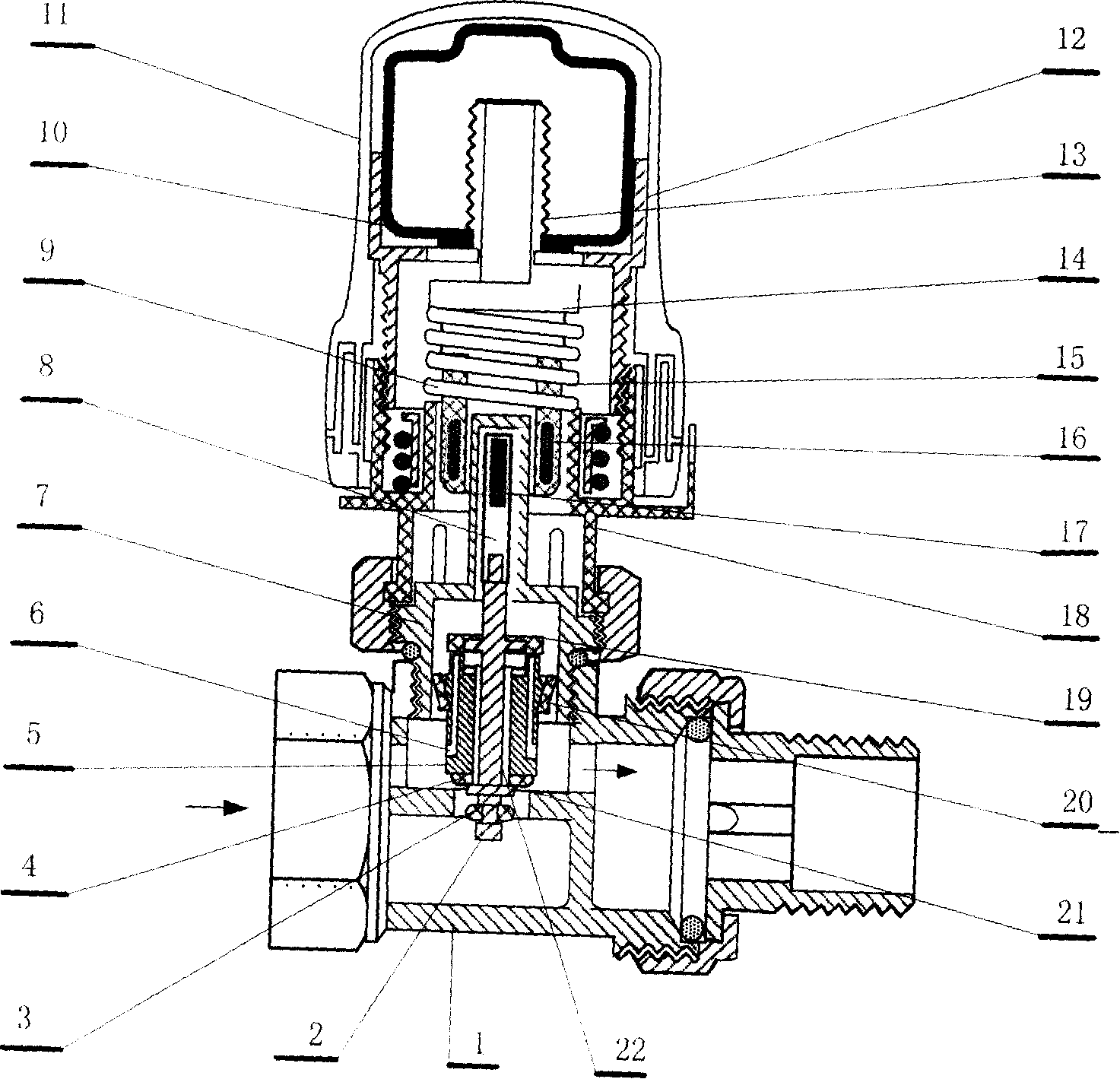

[0008] The temperature sensitive element of this embodiment adopts the structure of a liquid temperature bulb and a bellows. The entire structural composition is shown in the drawings and descriptions. Embodiments are now described in conjunction with the accompanying drawings.

[0009] On the upper part of the valve body (1) that enters and exits from the bottom, there is a valve cover (7) with a sleeve. In the inner cavity of the valve cover (7), there is a self-operated valve core and valve stem. The valve core is composed of upper and lower sealing rings. (4), composed of piston rod (5); valve stem is composed of upper valve stem (8), lower valve stem (2), magnetic column (17), rubber sleeve (3); upper valve stem (8) is on the valve cover (7) The inner cavity is inserted into the casing; the valve cover (7) outside the casing is covered with a circular sleeve (15) that can move up and down outside the casing, and a magnetic ring (16) is embedded in the circular sleeve (15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com