Synchronized dual rotors system inside and outside rotor unbalance value quick recognizing methods

A rotor unbalance and identification method technology, which is applied in the field of rapid identification of the unbalance of the inner and outer rotors of the synchronous dual rotor system, can solve problems such as decline and difficulty in ensuring assembly accuracy, and achieve the effect of improving balancing efficiency and reducing balancing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The method for quickly identifying the unbalance of inner and outer rotors in a synchronous dual rotor system includes the following steps:

[0038] 1) Install the reference signal sensor on the inner and outer rotors respectively, and install the vibration measuring sensor on the outer rotor;

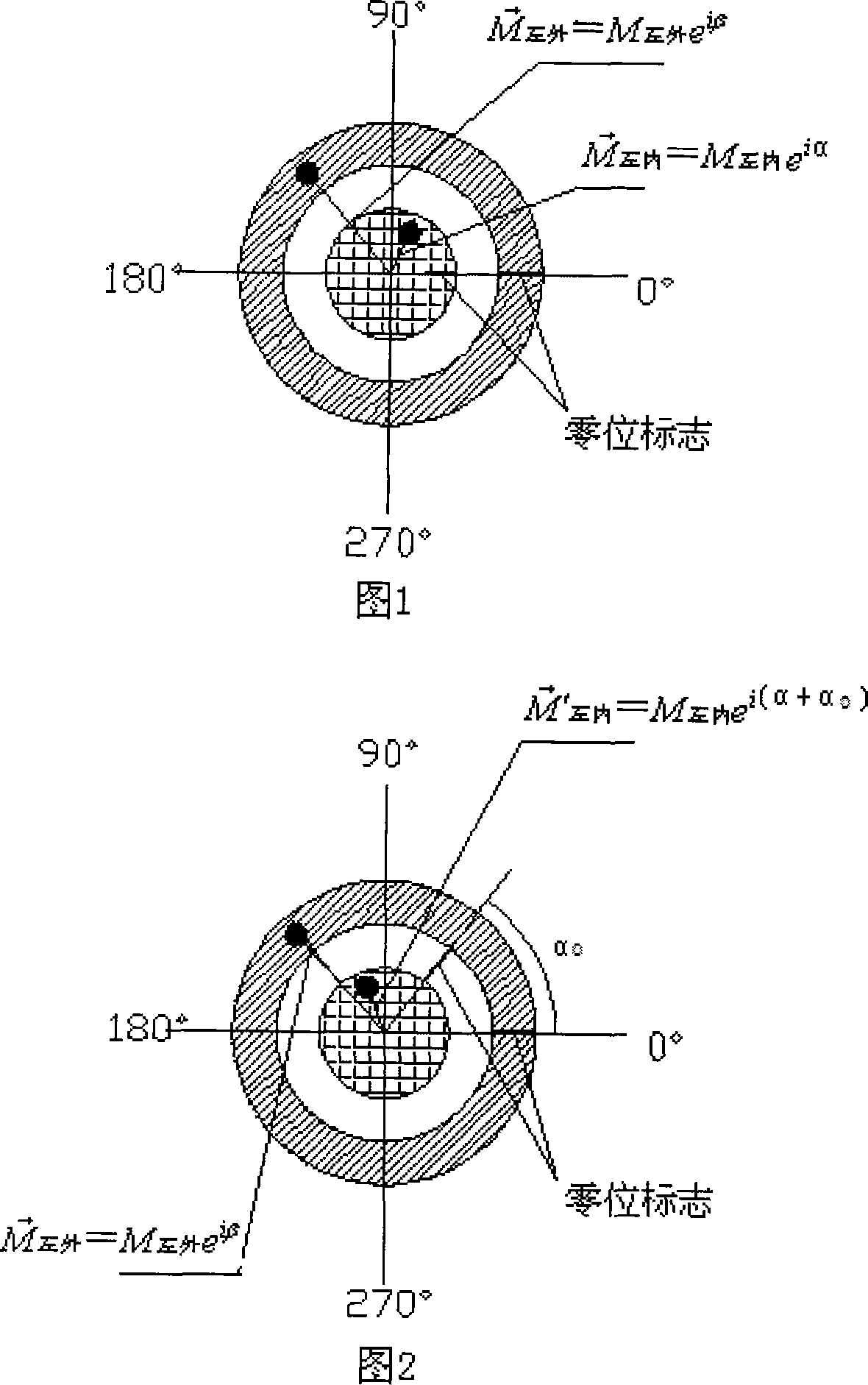

[0039] 2) Add a marking line at any circumferential position of the inner and outer rotors, and mark the angle in the circumferential direction, and make the inner and outer rotors 0 0 line overlap;

[0040] 3) Disengage the differential, change the connection mode of the transition flange in the differential, so that the inner and outer rotors rotate synchronously;

[0041] 4) Through two weight tests on the outer rotor, use the influence coefficient method to obtain the combined unbalance

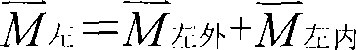

[0042] 5) Stop and stagger the inner and outer rotors by α 0 Angle, then make it rotate synchronously, use the influence coefficient method, and obtain it by adding weight twice on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com