Hoisting method for ultra-large ring-shape accessory and auxiliary hoisting tool

A technology for ring parts, lifting tools, applied in the direction of load hanging elements, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The lifting of the super large circular part of the present invention will be described in detail below in conjunction with the process of lifting a circular part with a weight greater than 15 tons and a diameter of more than 5 meters from the horizontal to the vertical and then transported to the installation position in conjunction with a diesel engine. method.

[0028] Utilize the hoisting method of super large annular part of the present invention to lift the super large annular part of marine diesel engine, mainly comprise following concrete steps:

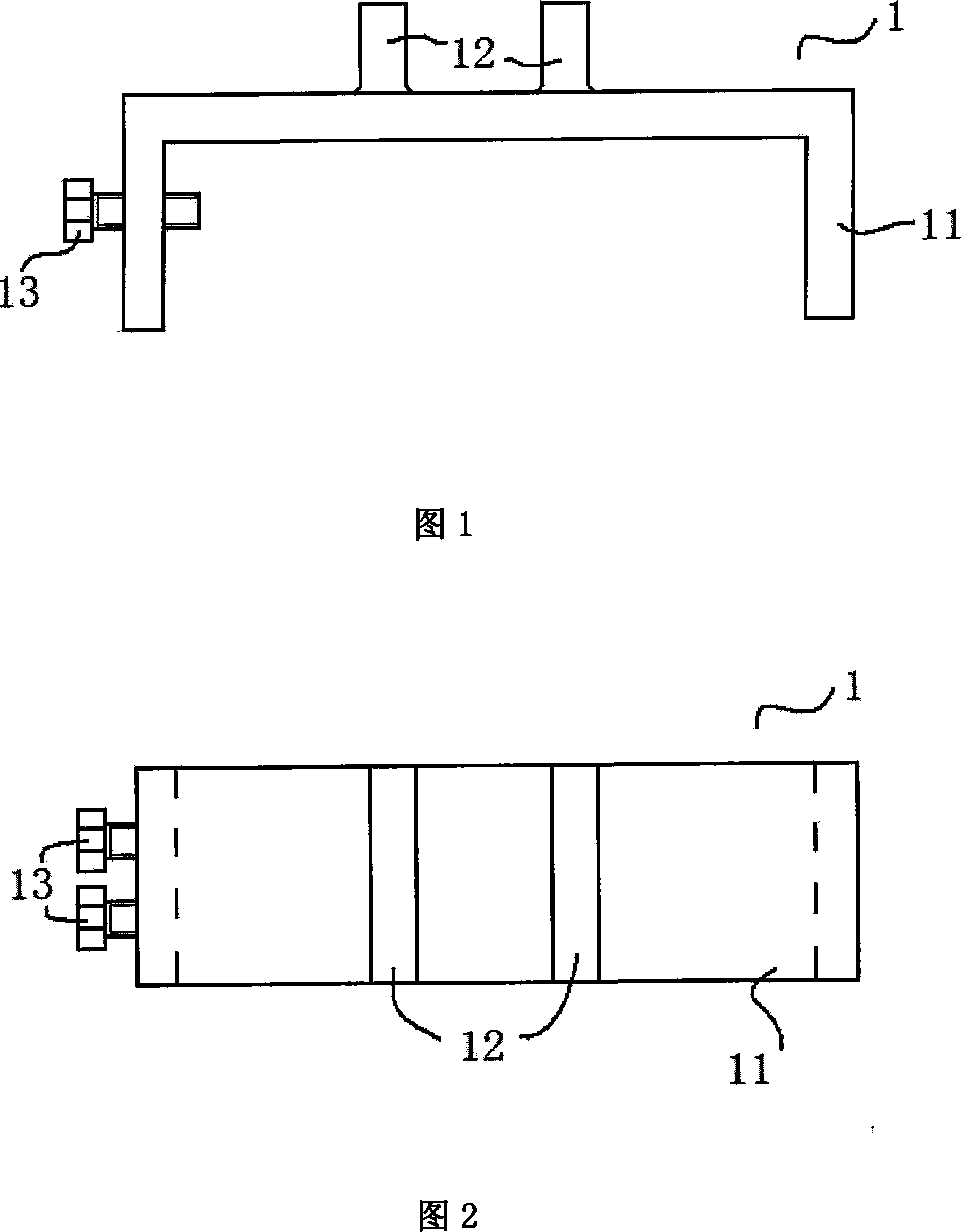

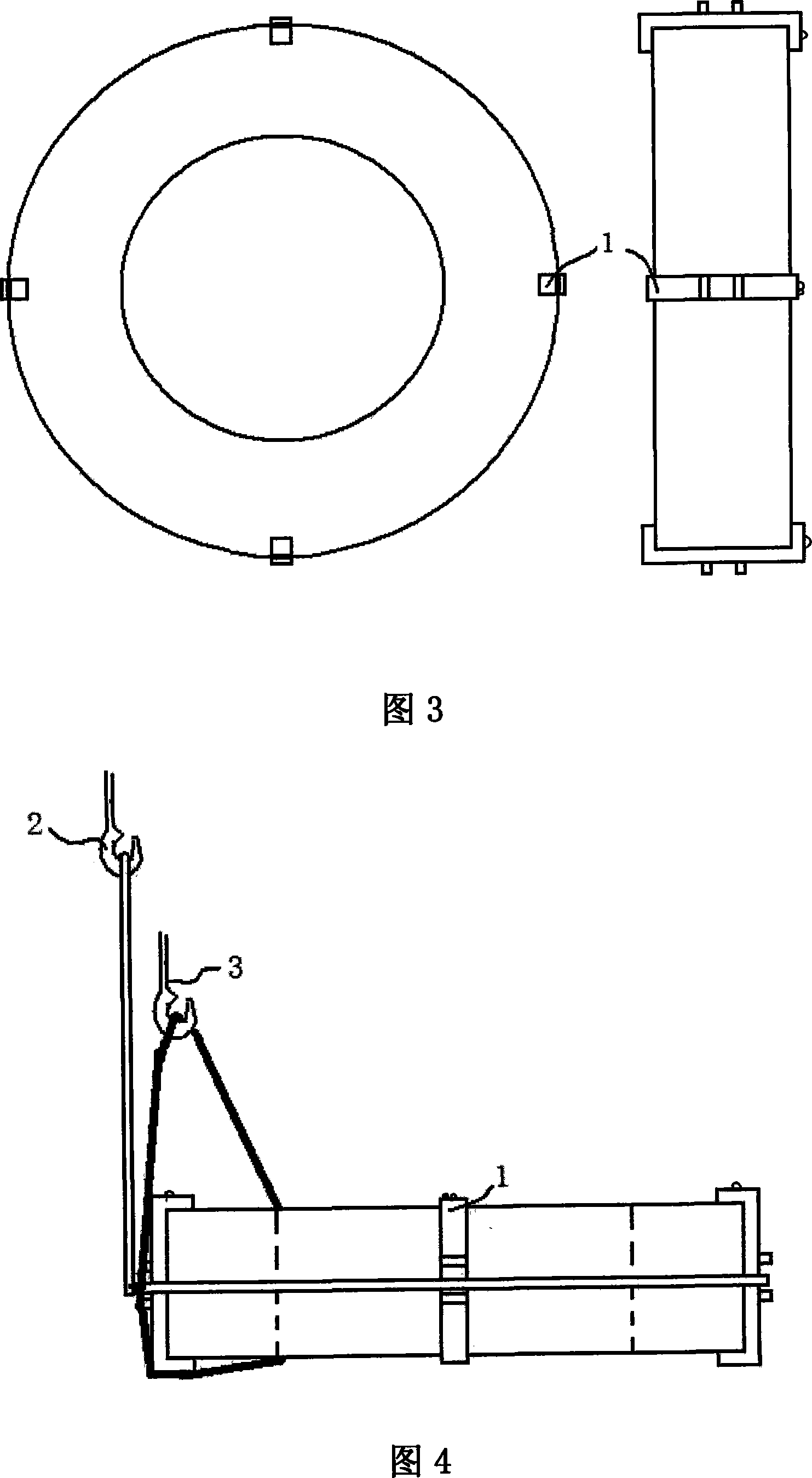

[0029] ① Fix four auxiliary lifting tools 1 on the circumference of the outer circle edge of the super large circular part placed horizontally. Bolt 13 is tightened, as shown in Figure 3;

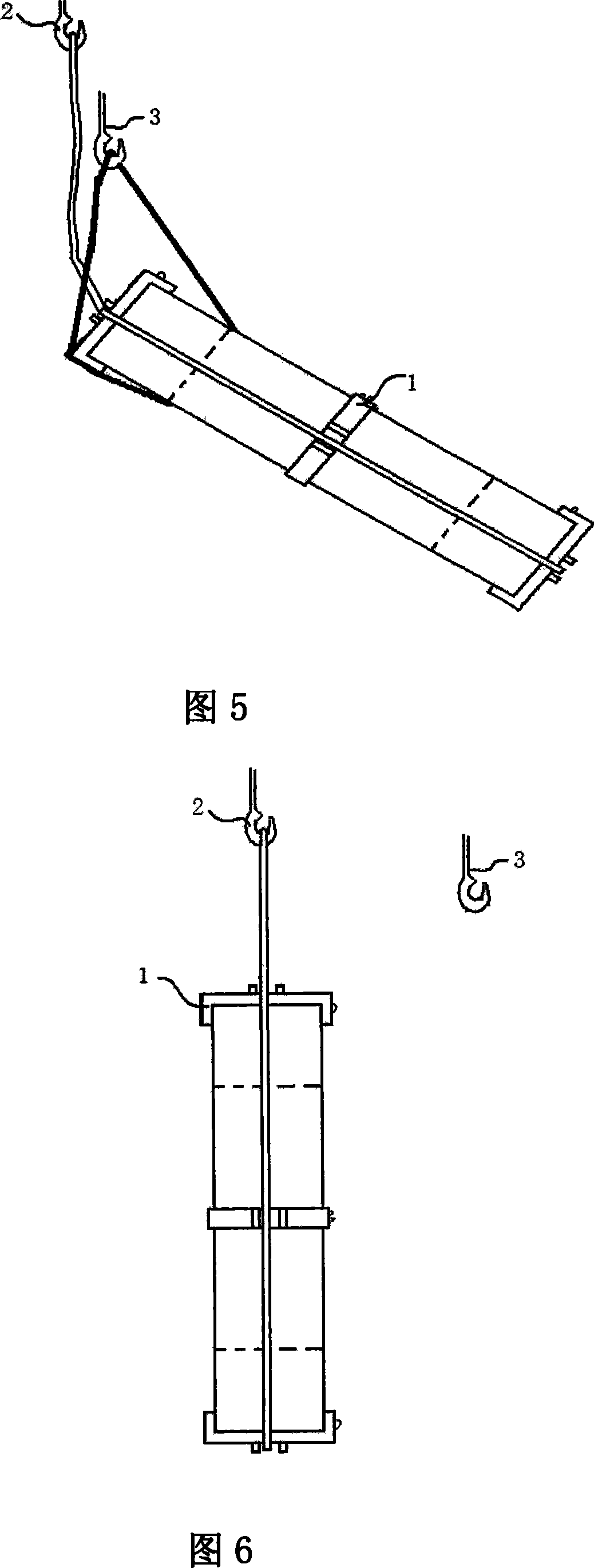

[0030] ②Use a hoisting device with main hook 2 and auxiliary hook 3 to move to the super large ring-shaped part placed horizontally, and first wrap the wire rope on the main hook 2 around the outer circumference of the super large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com