Automobile exhausting spark arrester

A spark extinguisher and motor vehicle technology, applied in the direction of exhaust devices, machines/engines, mechanical equipment, etc., can solve the problems of poor exhaust flow, large exhaust resistance, easy falling off and loading and unloading, etc., to eliminate sparks and flames, The exhaust gas flows out smoothly and realizes the effect of flameout function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Description will be made in conjunction with the accompanying drawings.

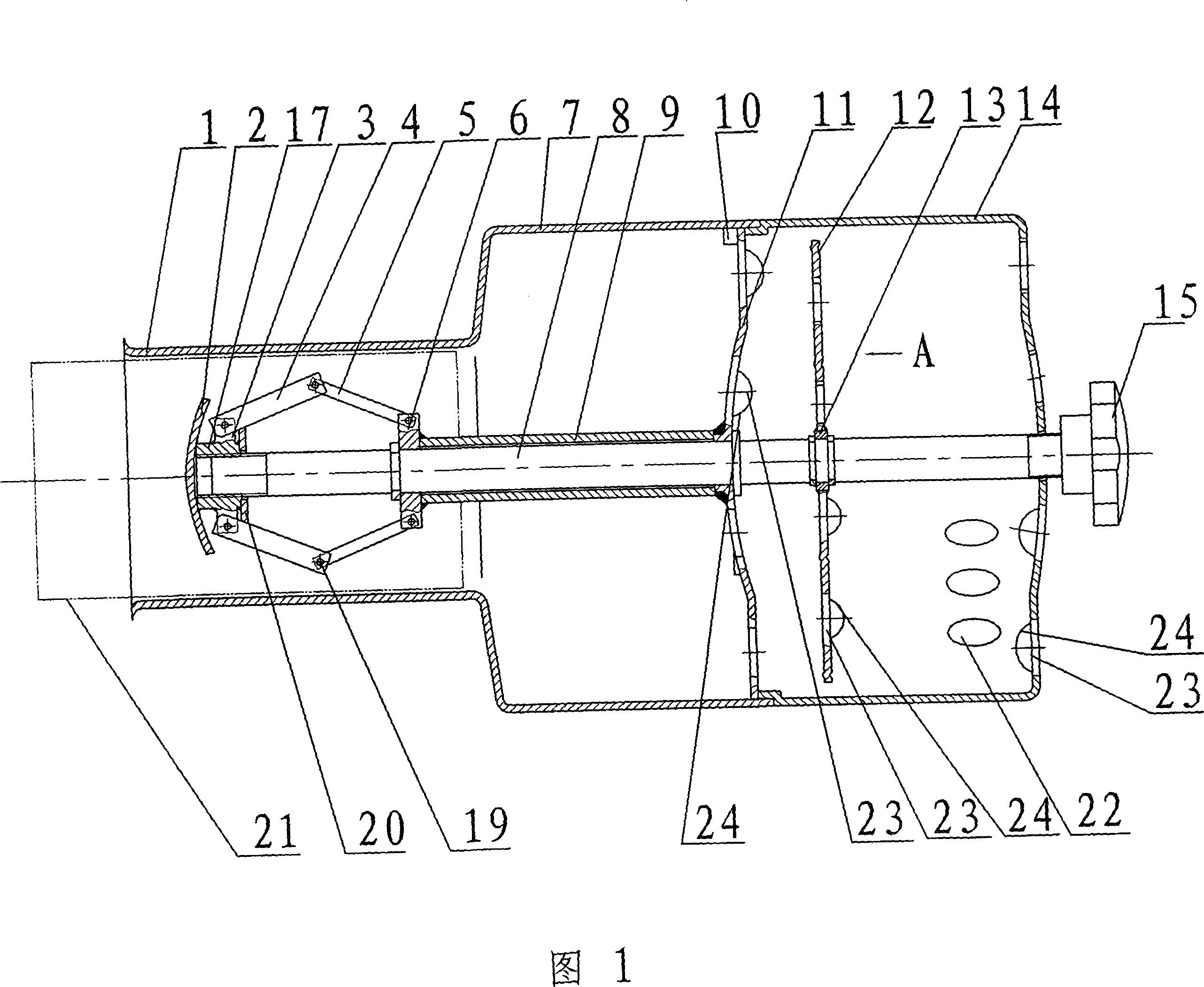

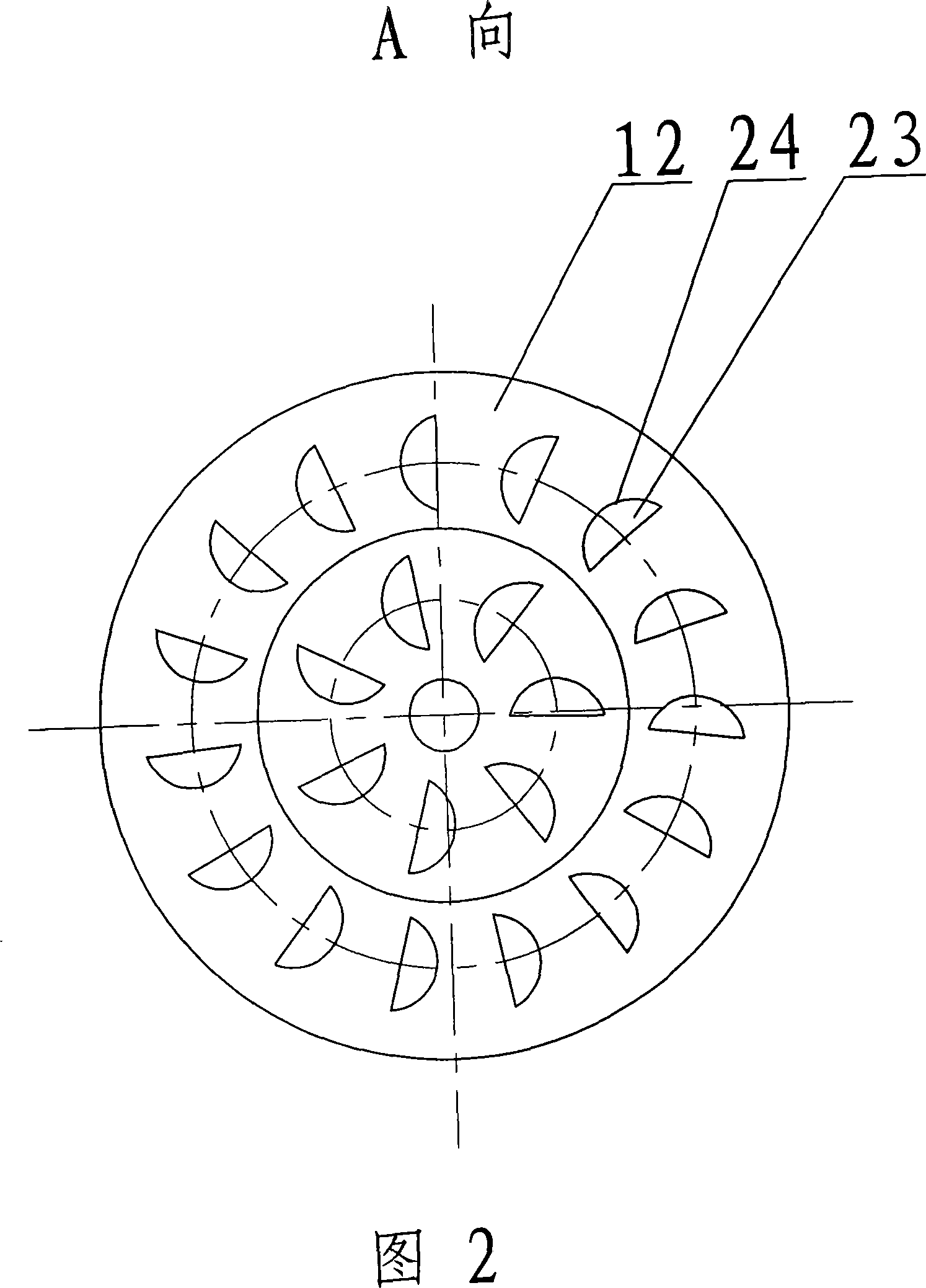

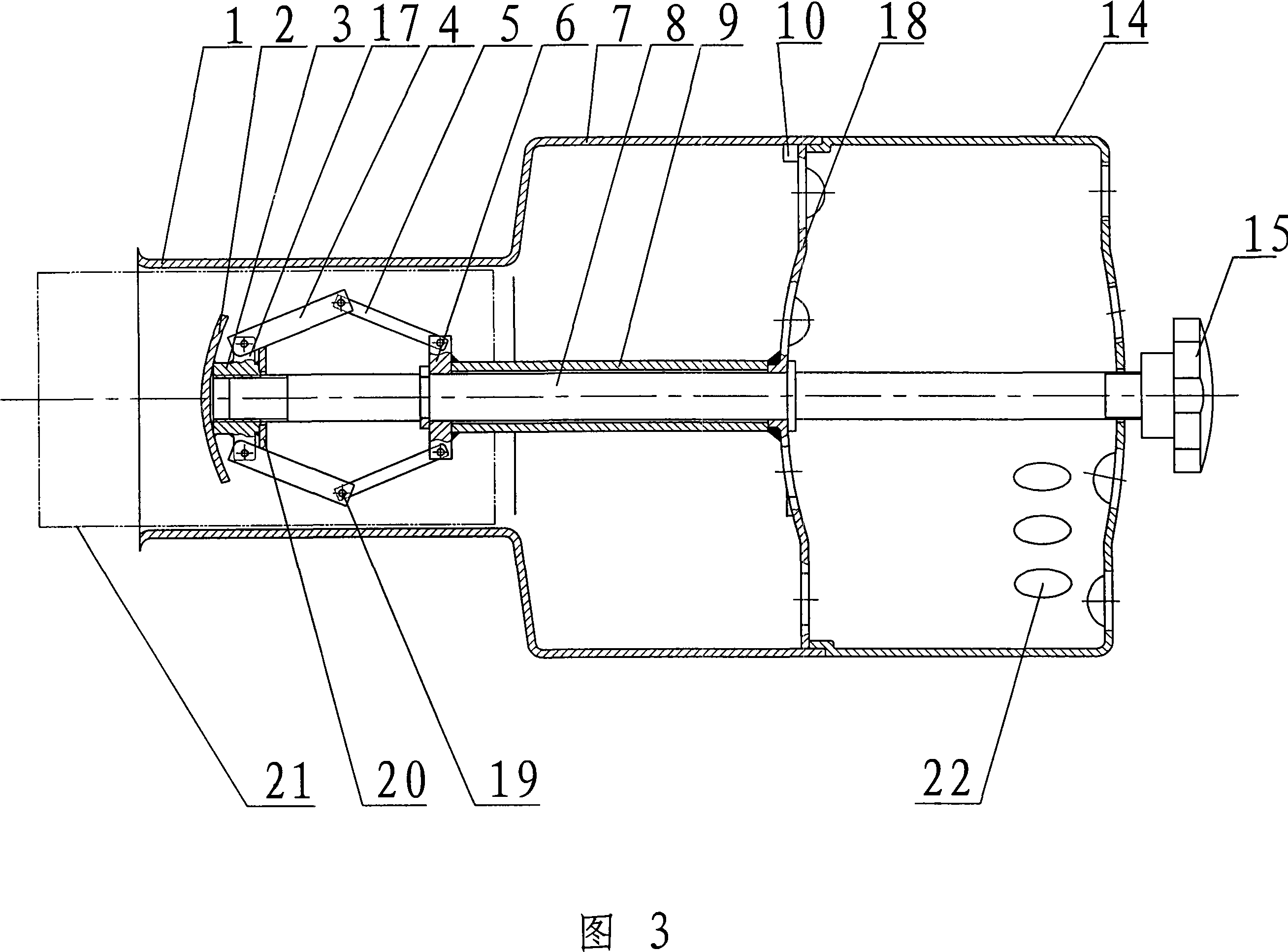

[0025]The housing of the motor vehicle exhaust spark extinguisher shown in Fig. 1 is made up of front housing 7 and rear housing 14, and the front part of front housing 7 is air inlet sleeve pipe 1, and the rear part of rear housing 14 is outlet breath. The deflector 11 is disc-shaped, and its outer edge is fixedly connected with the front shell 7 and the rear shell 14 through the positioning frame 10 as a whole. The central hole of the deflector 11 is slidingly fitted with the longitudinal central shaft 8 arranged along the front and rear directions of the casing, and the central shaft 8 is supported by the deflector 11 . The rear end of the central shaft 8 protrudes from the center of the air outlet and is fixedly connected to the star-shaped handle 15. The front part of the central shaft 8 cooperates with the tensioner 19, and the tensioner 19 is located on the inner cavity axis of the air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com