Weighing arrangement

A weighing and equipment technology, applied in the field of quantitative feeding mechanism, can solve problems such as inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

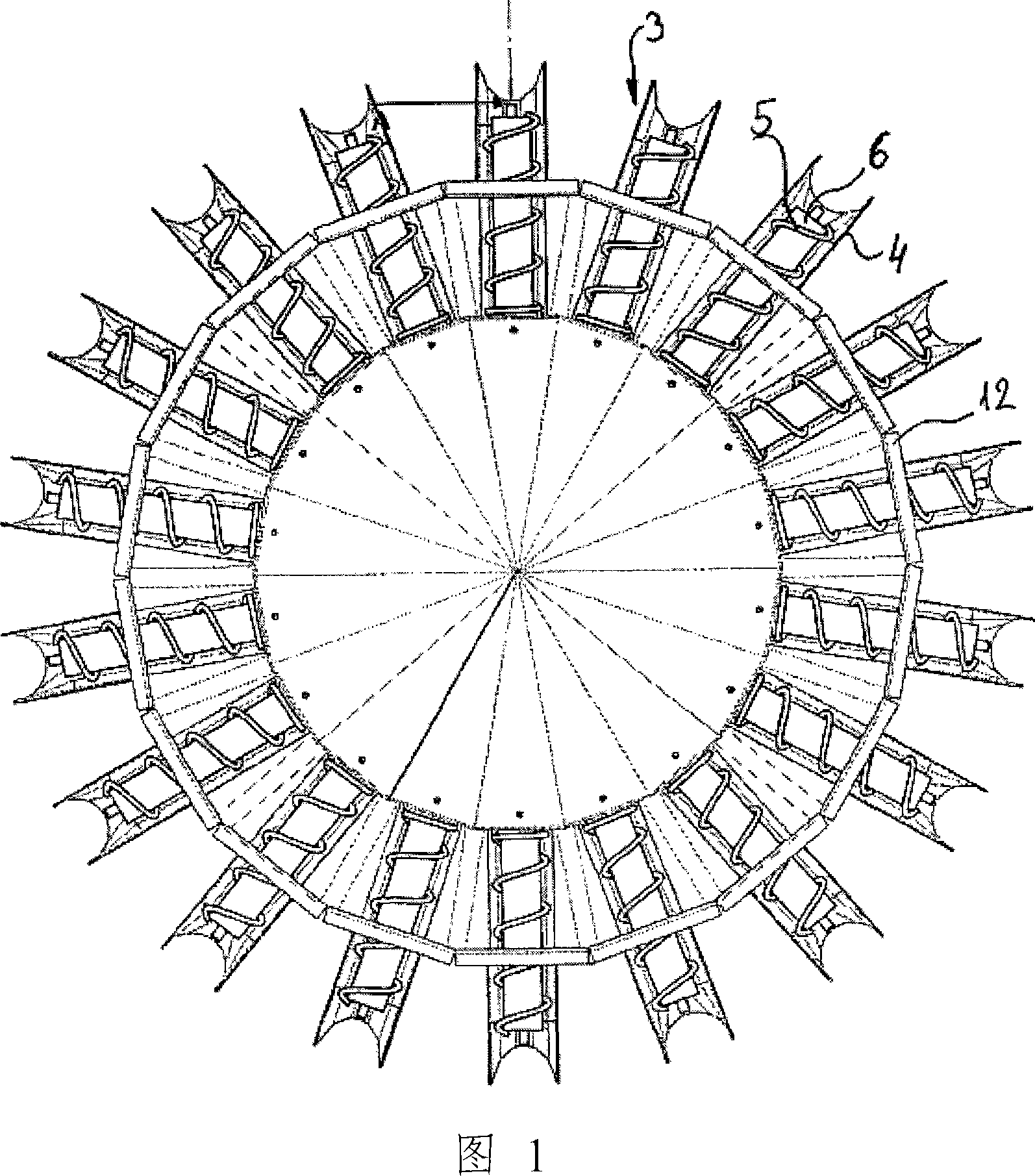

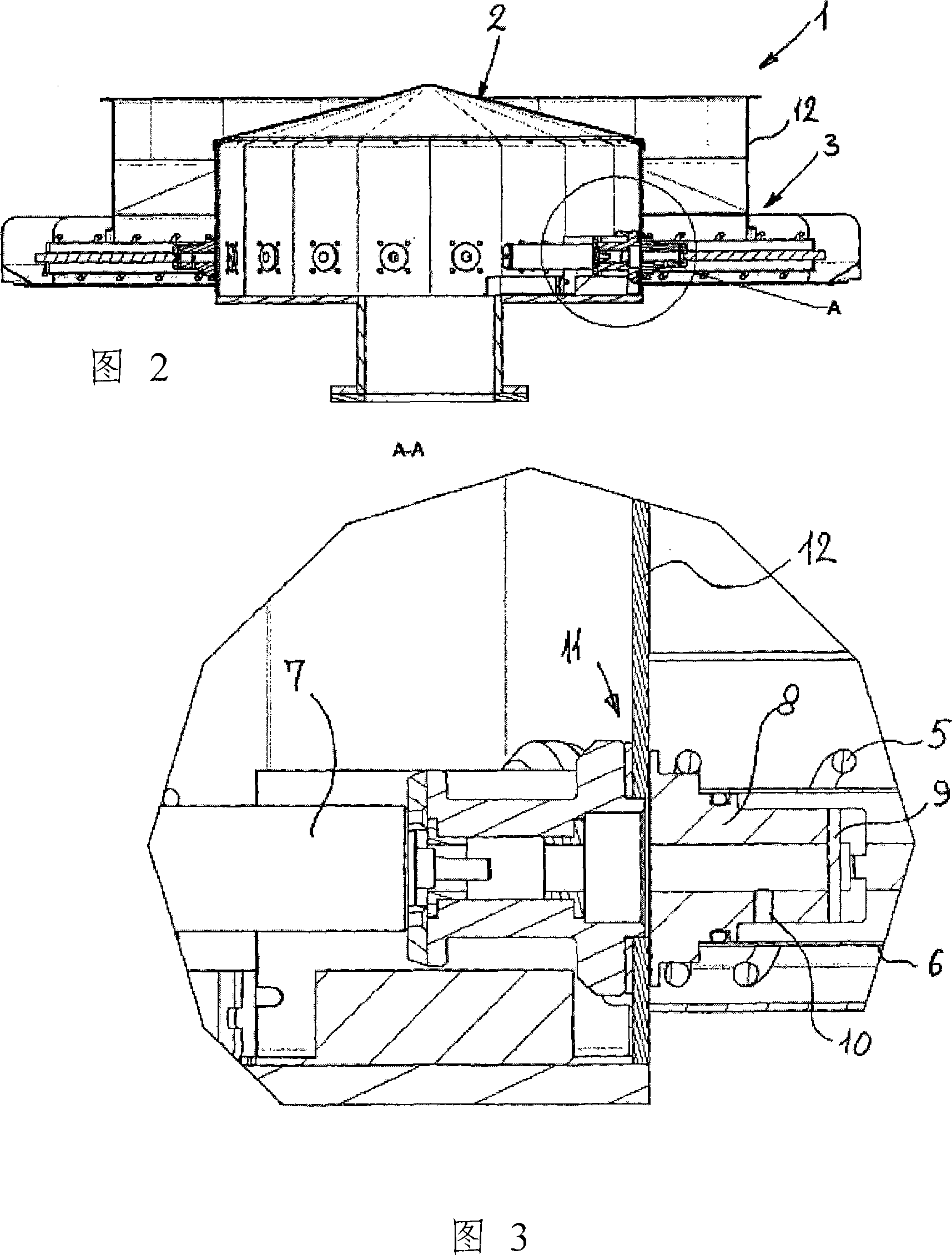

[0009] The device shown in FIG. 1 includes a feeder 1 having 18 quantitative feeding mechanisms 3 arranged symmetrically along the circumference of the feeder 1 . Each dosing mechanism 3 includes a groove 4, in which a screw-shaped conveying screw 5 is arranged, and the conveying screw 5 is driven by a motor 7 (see FIG. 3 ). The coaxial arrangement of the mandrel 6 and the conveying screw 5 is contemplated so that the mandrel 6 can have any diameter smaller than the internal diameter of the conveying screw 5 .

[0010] The feeder 1 , shown in section in FIG. 2 , comprises a conical central bottom 2 that distributes the product material to the outer wall 12 of the feeder 1 . The feeding end of the conical central bottom 2 is at a certain distance from the outer wall 12 of the feeder so that the product material falls into each trough 4 through this distance, in order to convey a controlled amount of product material to the bottom of the trough 4 end. The weighing system, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com