Centrifugal moving impeller, blade assembly and fan

A technology of centrifugal blades and moving impellers, applied in the field of fan impellers and fluid impeller machinery, can solve the problems of uneven air outlet, small air outlet, large resistance, etc., and achieve the effect of uniform air flow, stable air flow and small disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

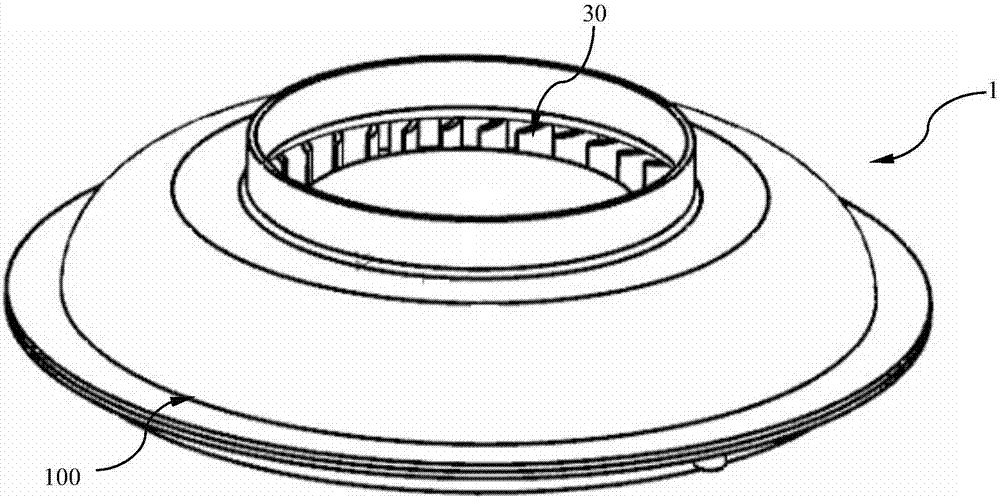

[0034] figure 1 It is a three-dimensional schematic diagram of the fan of the present invention.

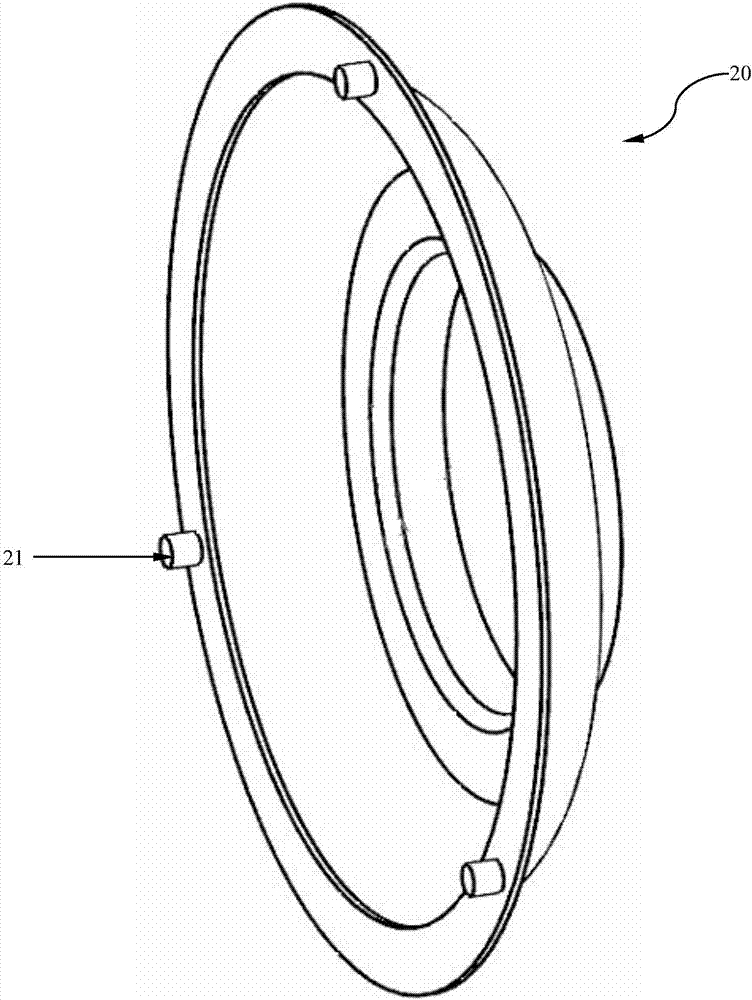

[0035] figure 2 for figure 1 view from the other direction.

[0036] image 3 It is a sectional view of the fan of the present invention.

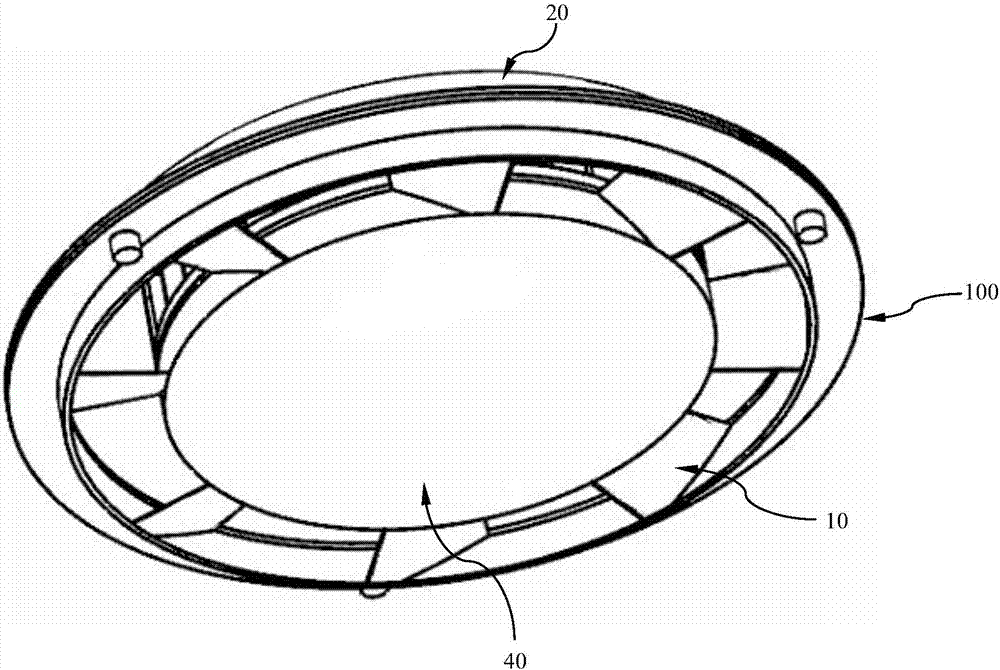

[0037] Figure 4 for image 3 view from the other direction.

[0038] Such as Figure 1-4 As shown, the fan 1 includes a prime mover (not shown in the figure) and a blade assembly 100, and the output shaft of the prime mover is connected to the blade assembly. In this embodiment, the fan is a small fan suitable for head-mounted air purifiers. Correspondingly, the prime mover is a permanent magnet DC motor, and its stator is a coil, and the rotating part is a magnet shell (which is used by the cooling fan of the cpu of a personal computer. micro motor).

[0039] Such as figure 2 , 3 As shown in , 4 , the blade assembly 100 includes an axial guide vane 10 , an annular cover 20 , a centrifugal impeller 30 and a rear cover 40 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com