Down-hole survival capsule

A technology of rescue cabin and living cabin, applied in the field of rescue cabin, it can solve the problems of unfavorable miners entering or withdrawing in time, complex structure of mine rescue cabin, etc., and achieve the effect of avoiding poisonous gas, simple structure and avoiding casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

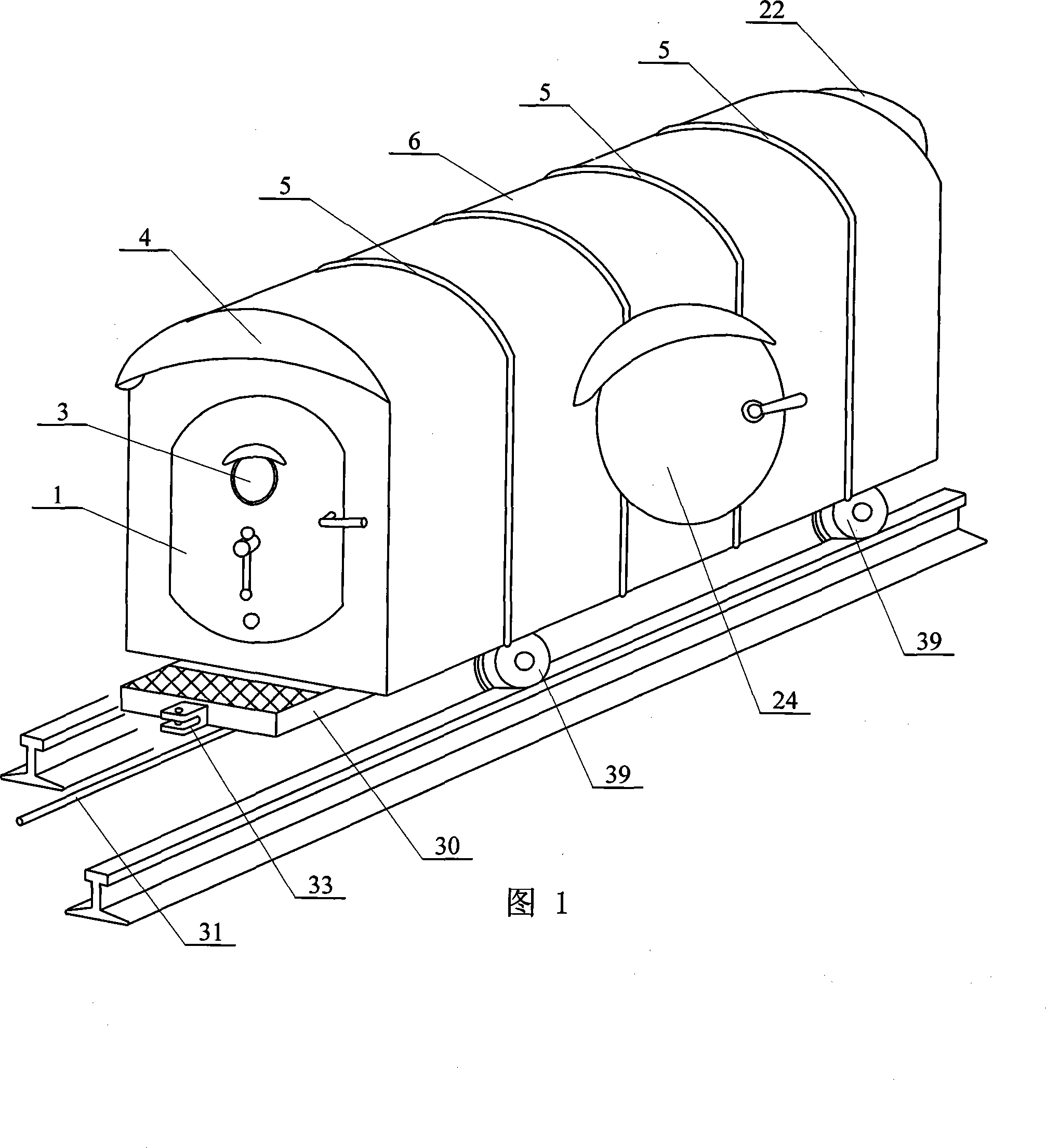

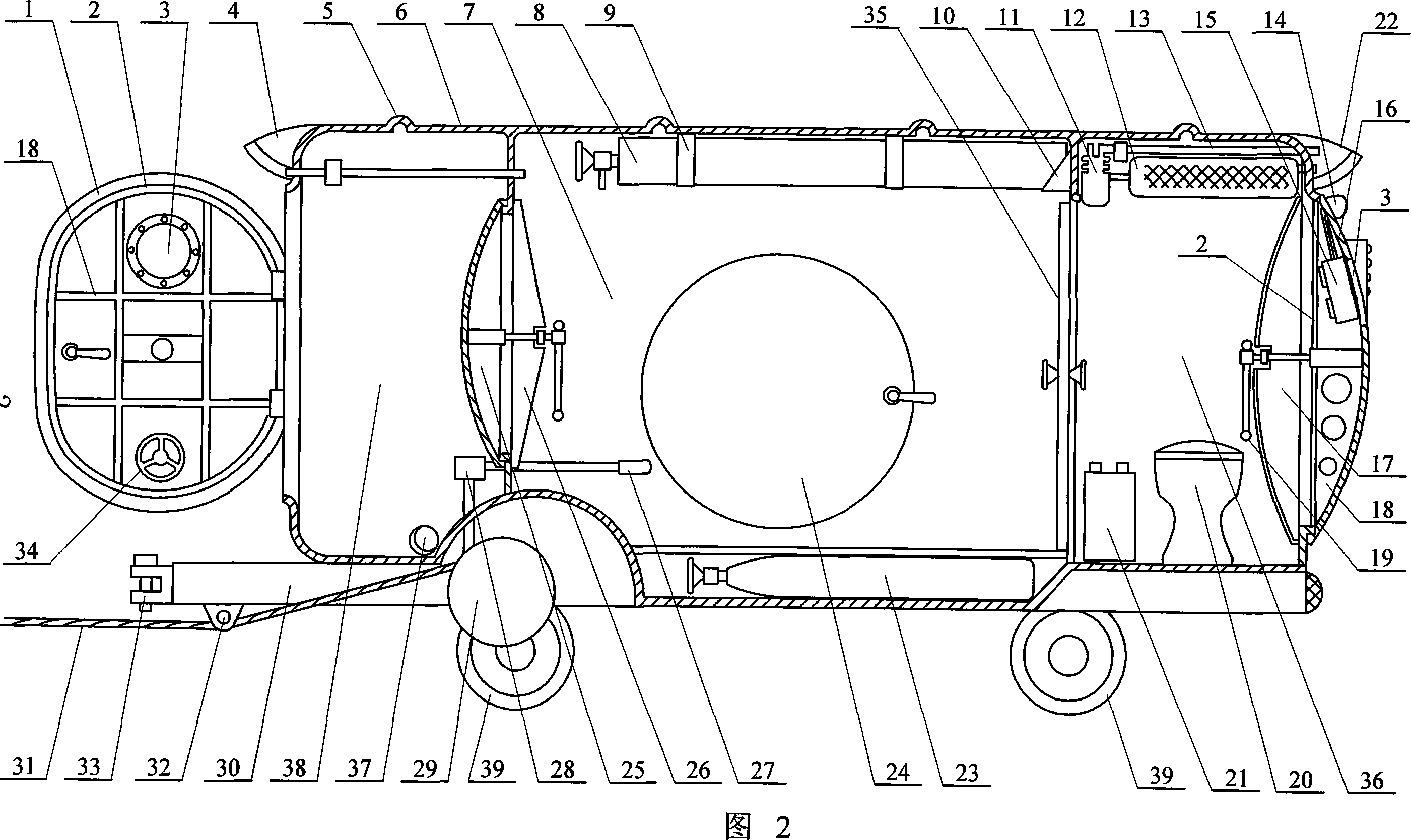

[0006] Specific embodiment one: (referring to Fig. 1~Fig. 2) present embodiment consists of front hatch door 1, cabin body 6, water storage device 8, water storage device fixing belt 9, water storage device bracket 10, rear hatch door 16, Rear hatch door fastening frame 17, rear hatch door fastening handle 19, oxygen generation or storage device 23, side hatch door 24, inner sealing hatch door 25, inner sealing hatch door fastening frame 26, connecting frame 30, water pump switch 34 , a partition door 35, a drain pump 37 and wheels 39, the wheels 39 are arranged at the bottom of the cabin body 6, the connecting frame 30 is fixed on the front side of the lower part of the cabin body 6, and the cabin body 6 is provided with reinforcing ribs 5, and inside the cabin body 6 There are three compartments that are both independent and connected to each other. The middle part in the cabin body 6 is the living cabin 7, the front part in the cabin body 6 is the transition cabin 38, the re...

specific Embodiment approach 2

[0007] Specific embodiment two: (see Fig. 2) the difference between this embodiment and specific embodiment one is that it increases manual air pump 11, air filter 12 and one-way exhaust pipe 13, manual air pump 11, air Filter 12 and one-way exhaust pipe 13 are all arranged on the top in service cabin 36, and one end of one-way exhaust pipe 13 is arranged on the outside of cabin body 6 and communicates with atmosphere, and the other end of one-way exhaust pipe 13 is connected with The exhaust port of the manual air pump 11 is connected, and one end of the air filter 12 is arranged on the outside of the cabin body 6 and communicates with the atmosphere, and the other end of the air filter 12 is connected with the air inlet of the manual air pump 11. The fresh air outlet of the air pump 11 communicates with the inside of the cabin body 6 . The setting of this embodiment is used under the condition that the downhole air contains oxygen, so as to prolong the service time of the ox...

specific Embodiment approach 3

[0008] Specific embodiment three: (referring to Fig. 2) the difference between this embodiment and specific embodiment two is that it has increased gas gas probe 14 and gas gas detector 15, and gas gas probe 14 is arranged on the outside of cabin body 6, and gas gas The gas detector 15 is arranged inside the cabin body 6, and the gas detector 15 is connected with the gas probe 14 through wires. The gas probe 14 and the gas detector 15 provided in this embodiment have two functions. The first function is to remind the miners to take emergency measures in time when the gas gas in the mine exceeds the standard. The second function is that the escape personnel can Grasp the concentration of gas outside the cabin and communicate with the ground in time to take corresponding rescue measures. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com