Photographic camera automatic rocking-pickup device

A camera, automatic technology, applied to the camera body, camera, support machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the present invention will be described in detail through examples and drawings.

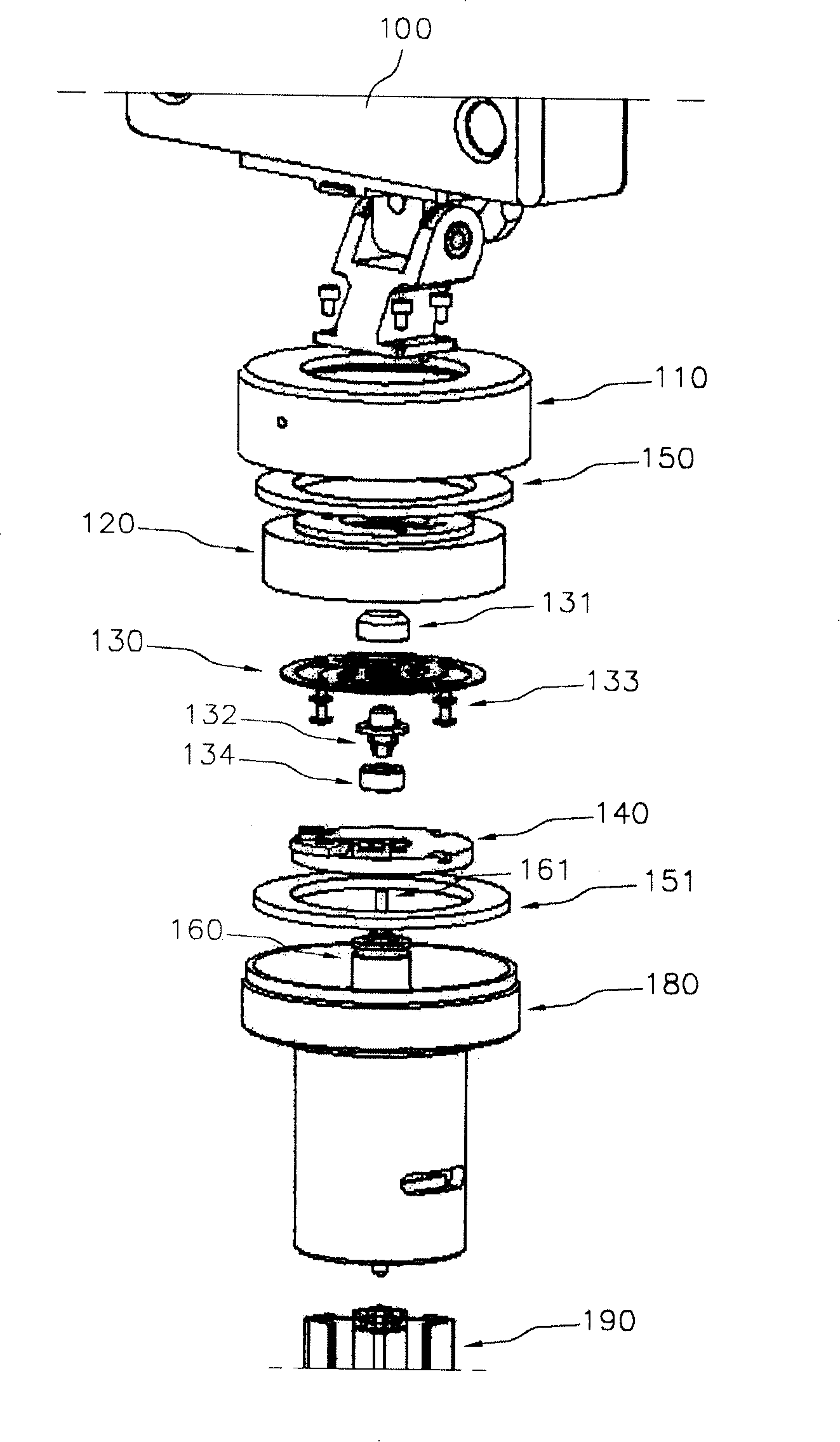

[0038] image 3 It is an exploded perspective view showing each component of the present invention. The present invention is characterized in that the load on the camera unit is distributed, and most of the load is transmitted to structures other than the spindle motor, such as the cover, to greatly reduce the load on the output shaft of the spindle motor.

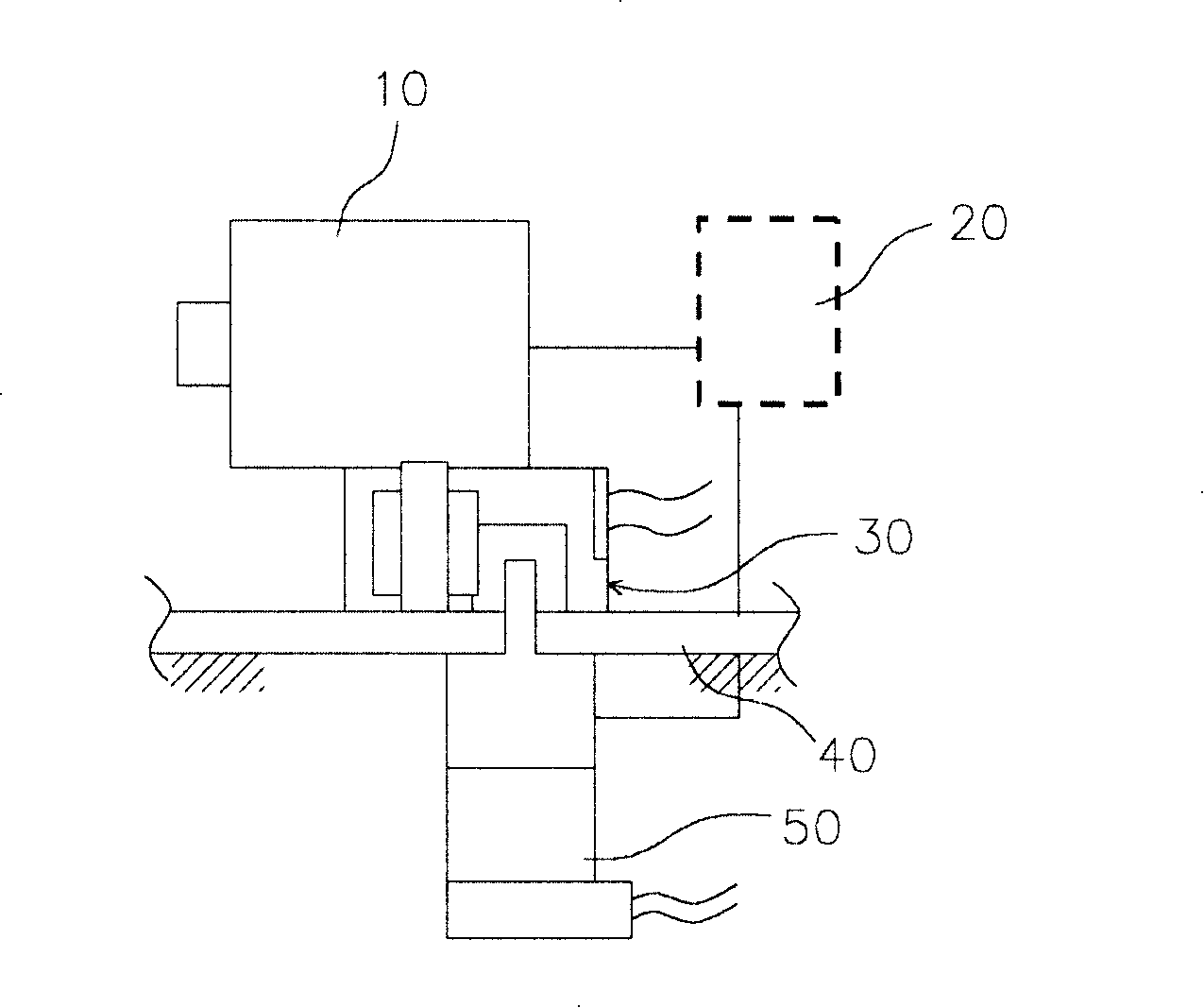

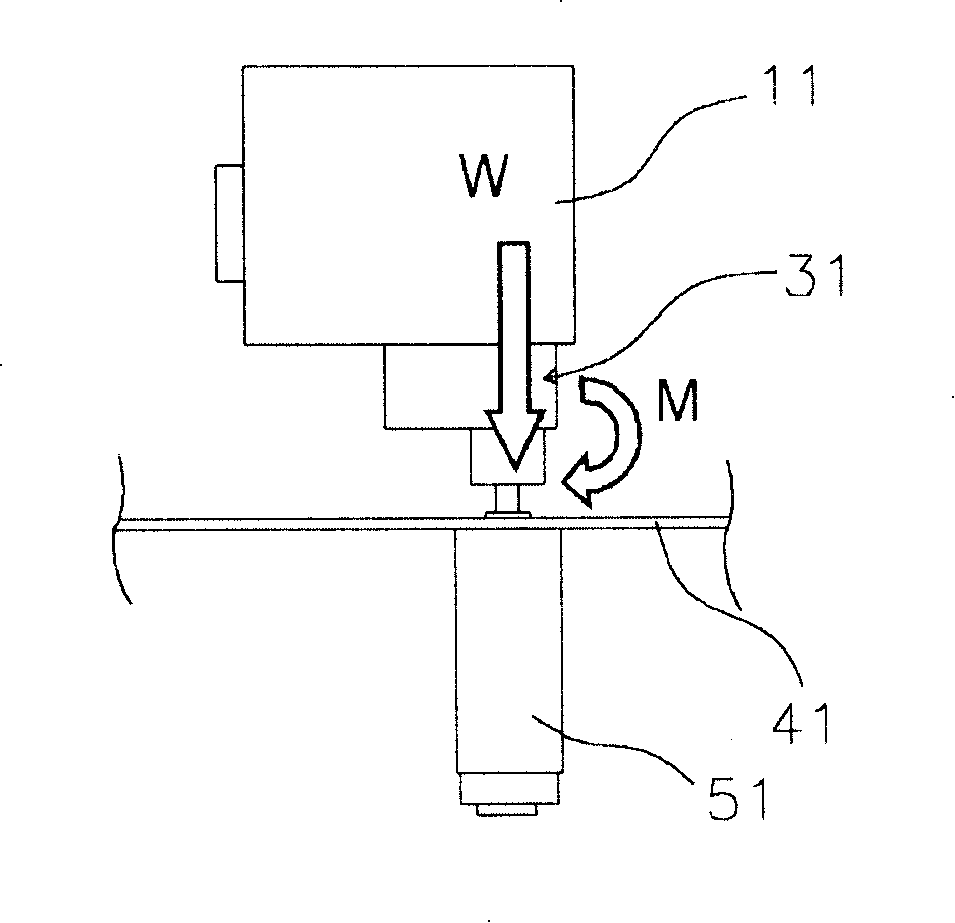

[0039] The present invention is based on the fixed part 190 and enables the camera part 100 to perform a horizontal rotation movement of the panning device. It consists of the following parts: the cover and cover that form the shape; the main shaft motor that generates power; the rotor installed in the above-mentioned camera; the coupler that connects the main shaft motor and the rotor; Bearings for cover transmission.

[0040] A space for accommodating the spindle motor 160 is formed inside the covering cover 180 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com