Solar cell louver and method of manufacture

A technology of solar cells and solar cell groups, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., and can solve problems such as shifting of solar cell skylight glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

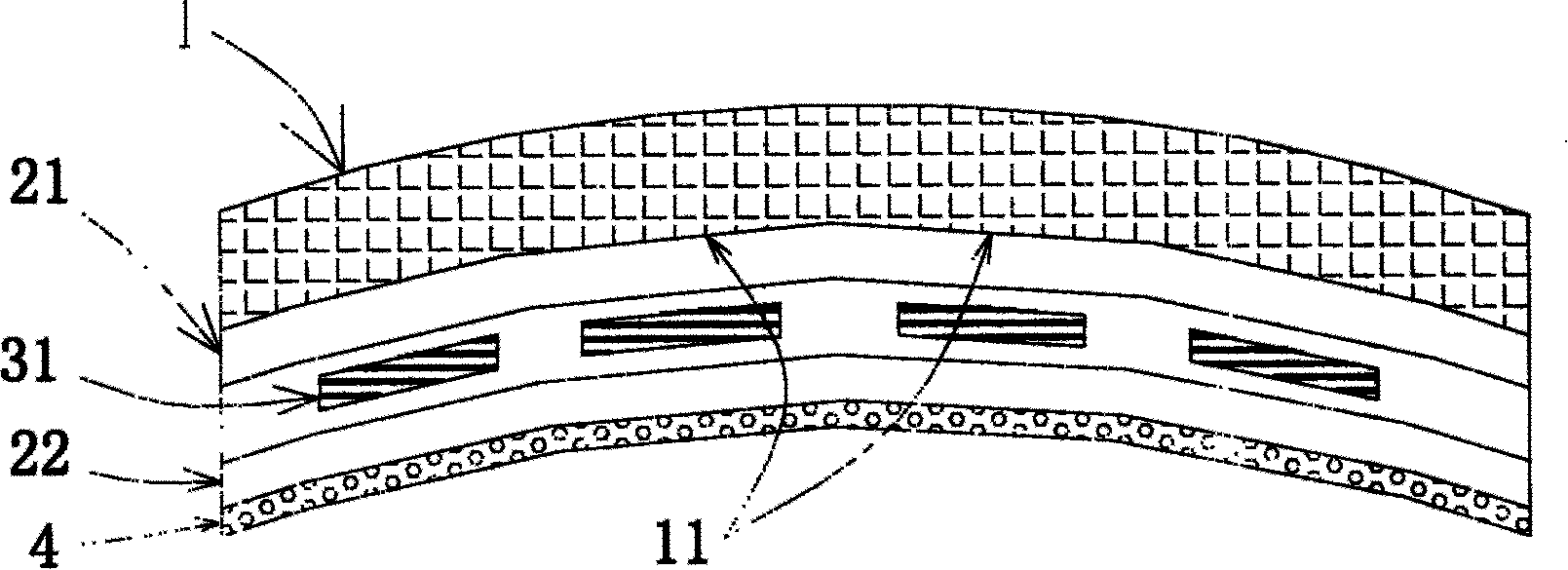

[0019] Embodiments of the present invention will be described in detail below with reference to the drawings.

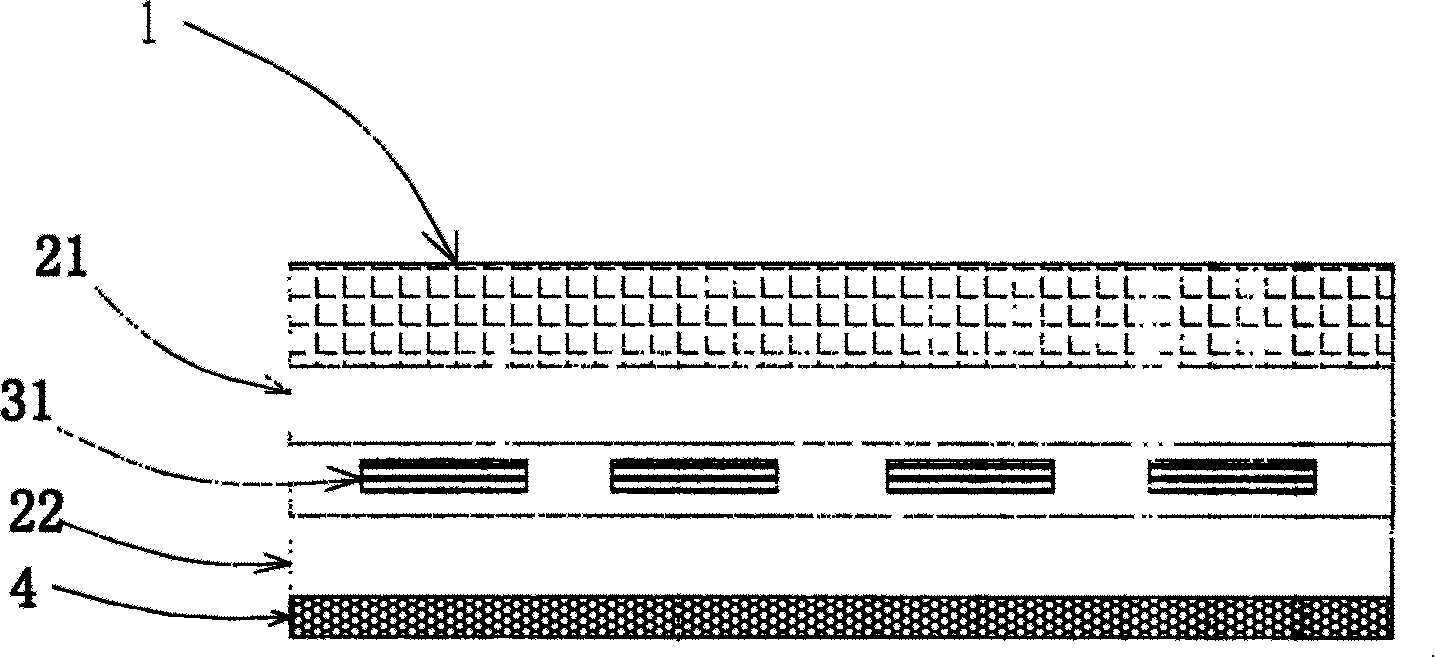

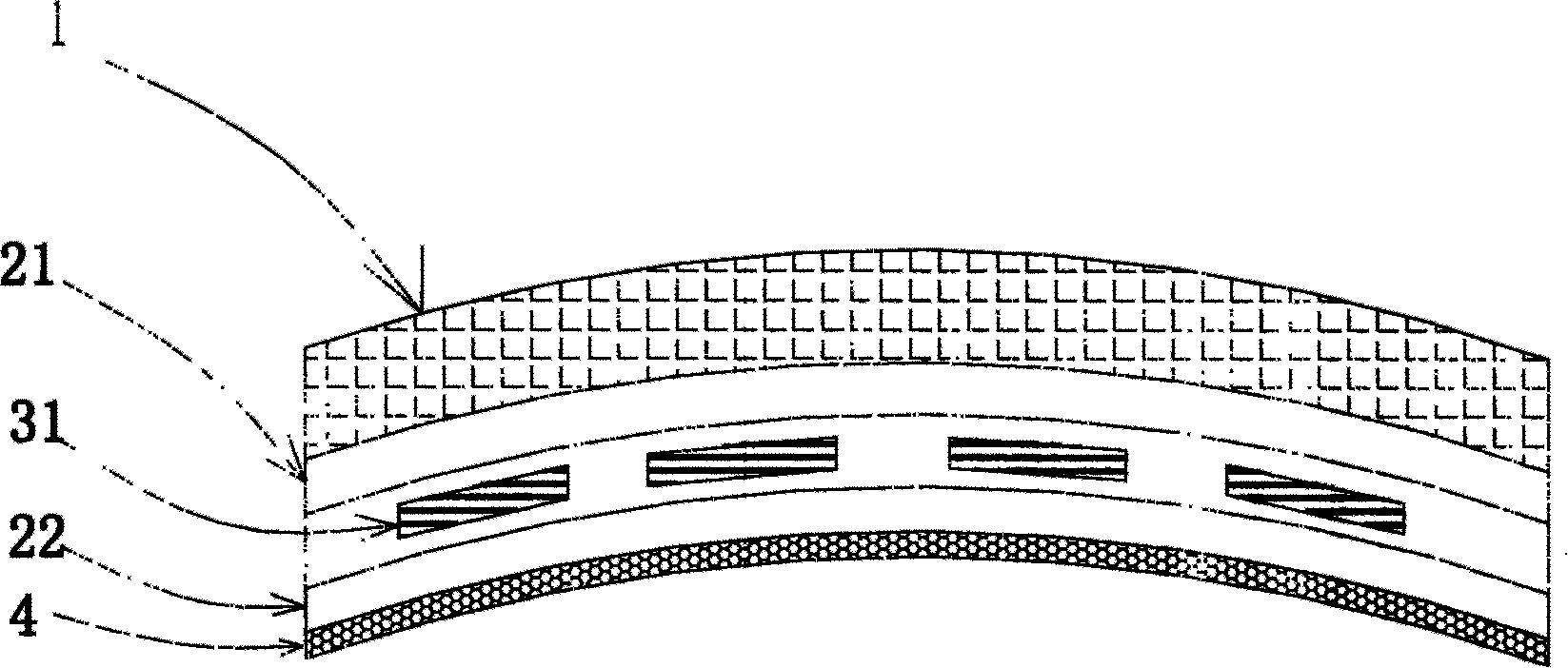

[0020] figure 1 and figure 2 It is a schematic diagram of two solar cell skylights in the prior art.

[0021] figure 1 The solar cell skylight in the solar panel is a flat structure. Since the roof of the car is usually in a curved structure, installing the solar cell sunroof on the car will make the roof of the car not smooth enough and thus unsightly.

[0022] figure 2 The solar cell skylight in the center is an arc-shaped structure. Installing the solar battery sunroof on a general automobile can overcome the above-mentioned shortcomings of the flat solar battery sunroof. However, in this curved solar cell sunroof, since the solar cells 31 are usually fragile monocrystalline silicon, polycrystalline silicon or amorphous silicon cells, when these cells are laminated together with the curved skylight glass 1 , it is easy to cause the battery chip to break. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com