Top roll support and loading arm

A technology of loading arm and load level, applied in the direction of textile and paper making, drafting equipment, spinning machine, etc., can solve the problem of not being able to check quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

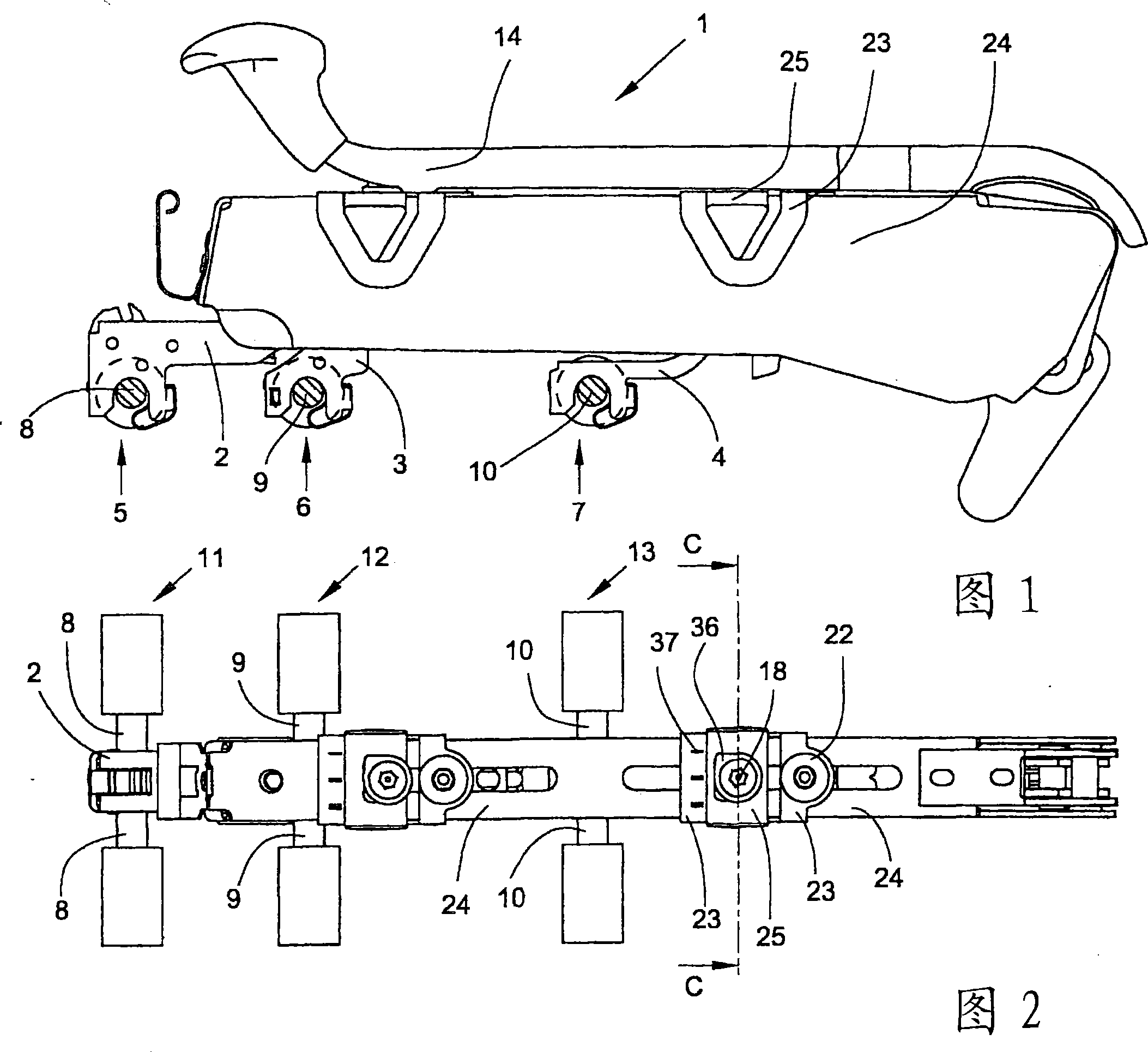

[0041] Figure 1 shows the longitudinal side of a top roller support and loading arm 1 of a drafting device of a spinning machine in an operative position with adjustable clamping means for the top rollers. The relevant top view in FIG. 2 shows the top roller support and loading arm 1 without the operating lever 14, so that the support profile 24 of the top roller supporting and loading arm 1 is shown in such a way that when the operating lever 14 is folded upwards, the support profile Item 24 appears in the operator's field of view. The gripping device comprises grippers 2 , 3 , 4 for respective top rollers, each arranged as output roller 11 , center roller 12 and input roller 13 . The top rollers are configured as double rollers and are rotatably clamped with their axes 8 , 9 , 10 in receptacles 5 , 6 , 7 of the grippers 2 , 3 , 4 .

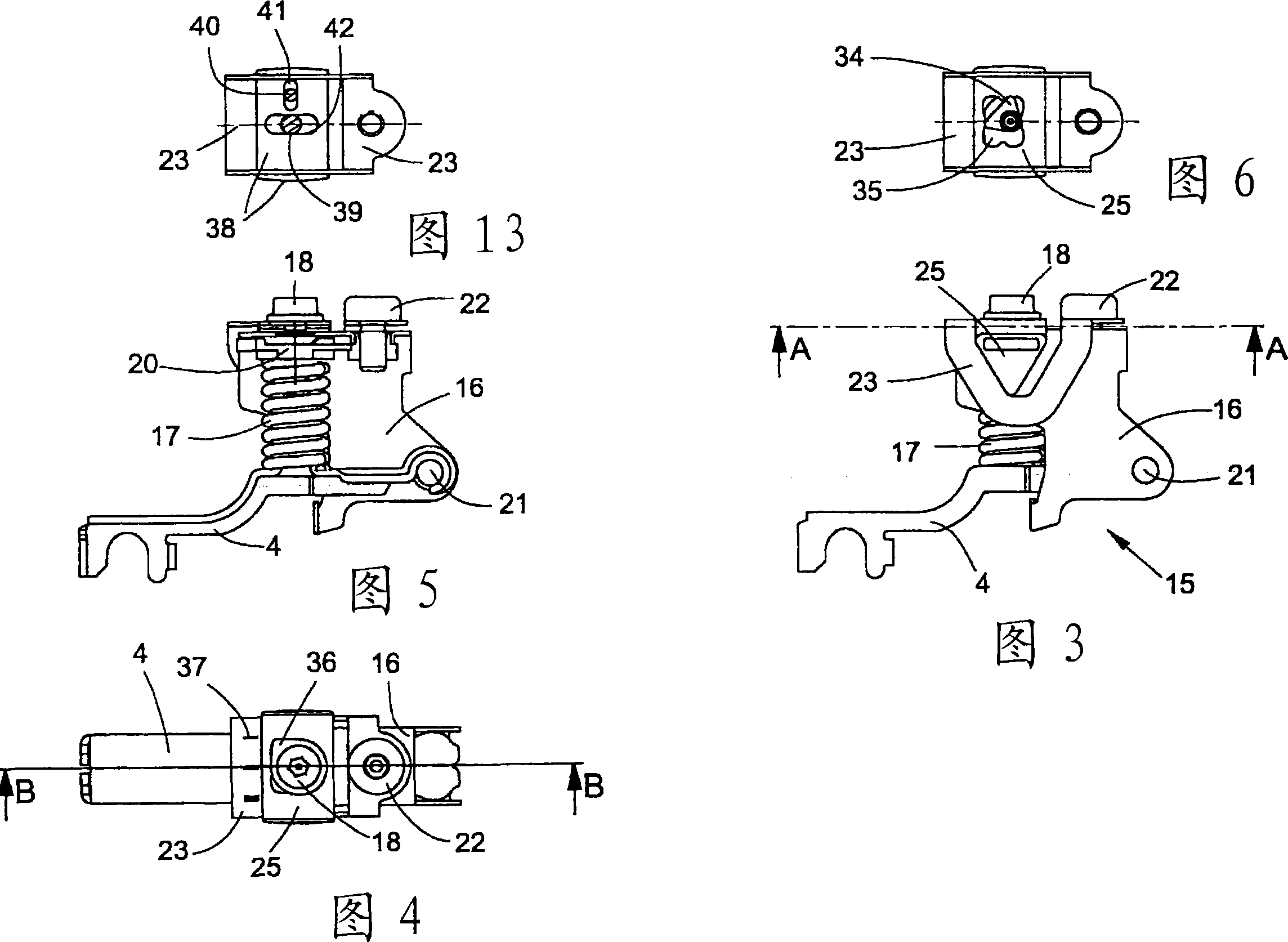

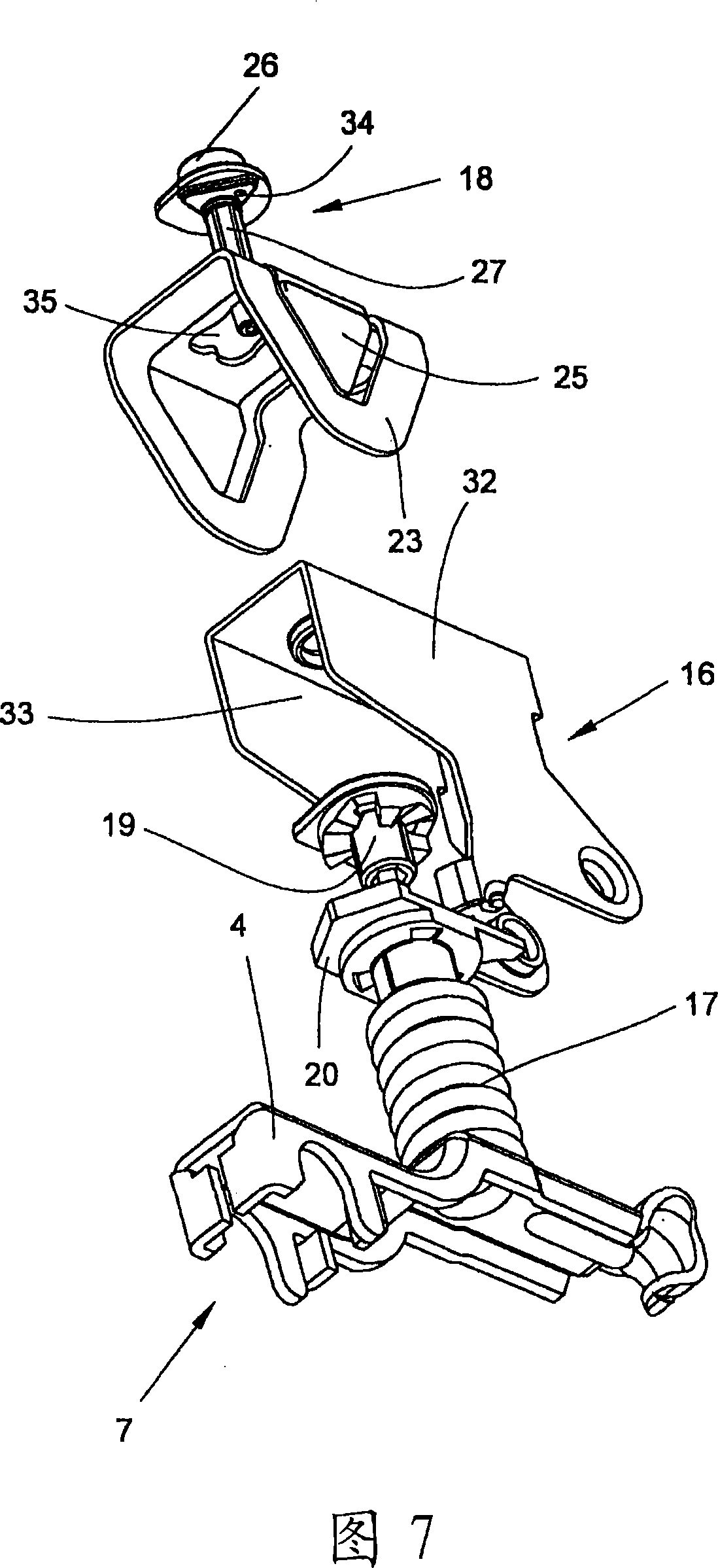

[0042] For better clarity, Figures 3, 4, 5, 6 and 7 respectively represent a clamping device 15 without a support profile 24, which clamping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com