Belt transfer device

A transfer and belt transfer technology, applied in electrography, optics, instruments, etc., to solve the problems of length error, image quality degradation, and toner image transfer performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

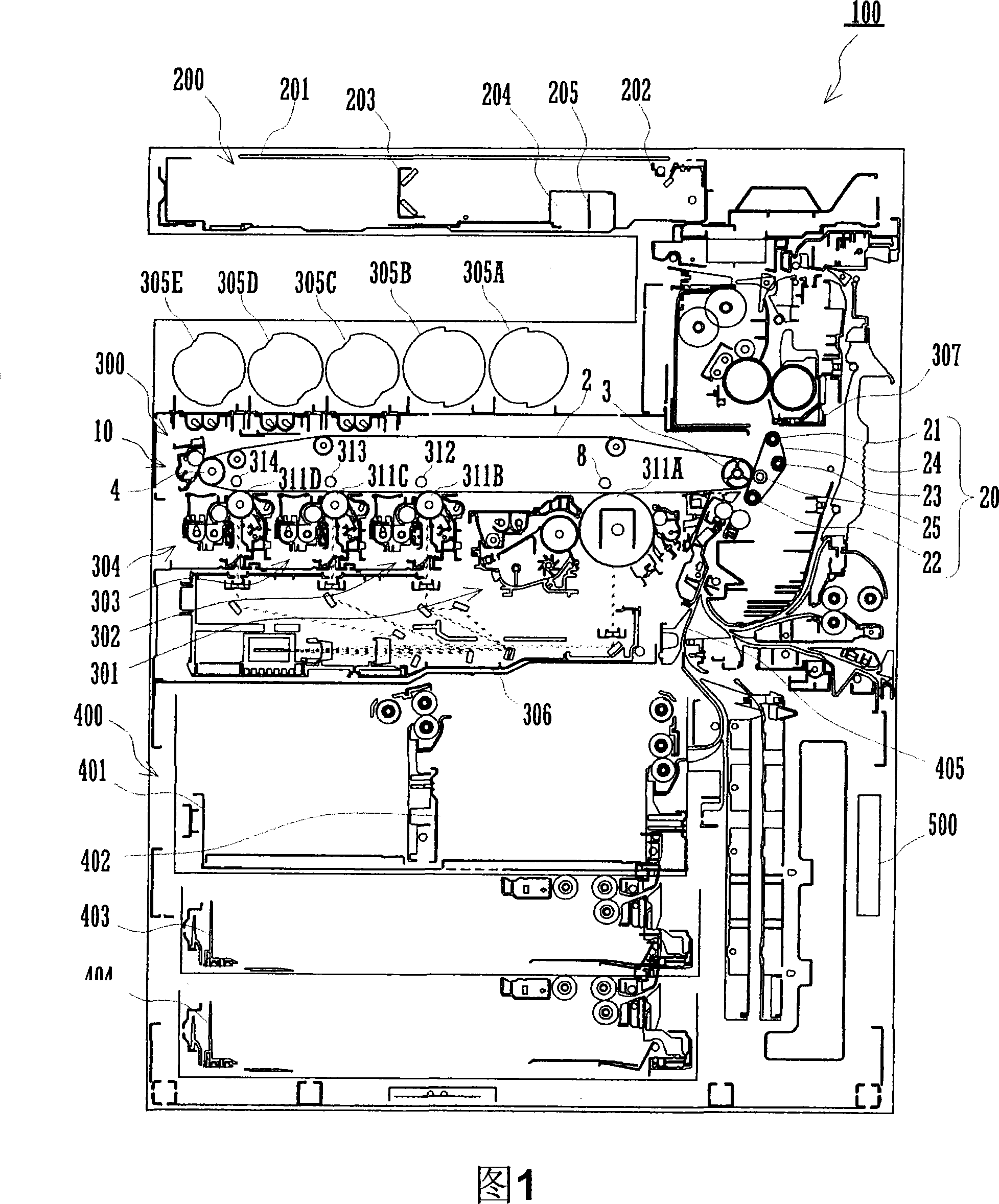

[0017] Hereinafter, the best mode for carrying out the present invention will be described when it is applied to a color image forming apparatus. FIG. 1 is a schematic diagram of a color image forming apparatus to which a belt transfer device according to an embodiment of the present invention is applied. Image forming apparatus 100 includes an image reading unit 200 , an image recording unit 300 , a paper feeding unit 400 , and a control unit 500 .

[0018] The image reading unit 200 includes a document table 201 , a first mirror base 202 , a second mirror base 203 , a lens 204 , and a solid-state imaging device (eg, CCD: Charge Coupled Device) 205 .

[0019] The original table 201 is made of a hard glass plate, and an original is placed on the upper surface. The first mirror base 202 mounts a light source and a first mirror. The second mirror base 203 mounts a second mirror and a third mirror.

[0020] The first mirror base 202 and the second mirror base 203 are free to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com