Brake power generator for a hydraulic vehicle braking system

A vehicle braking and braking force technology, which is applied to electric braking systems, brakes, vehicle components, etc., can solve the problems of complex structure, complex assembly and design, and large structural volume of the braking system, so as to avoid large structural volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

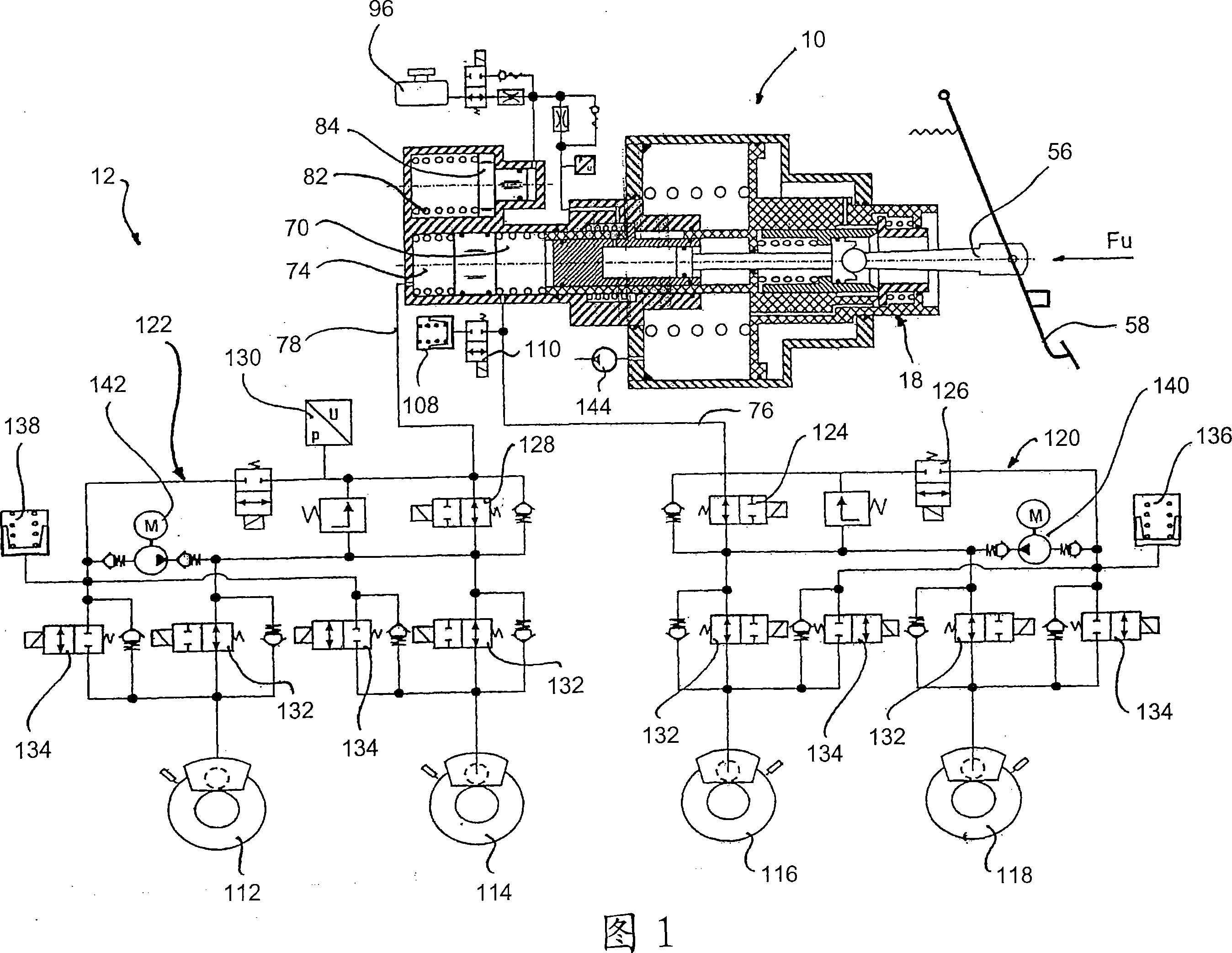

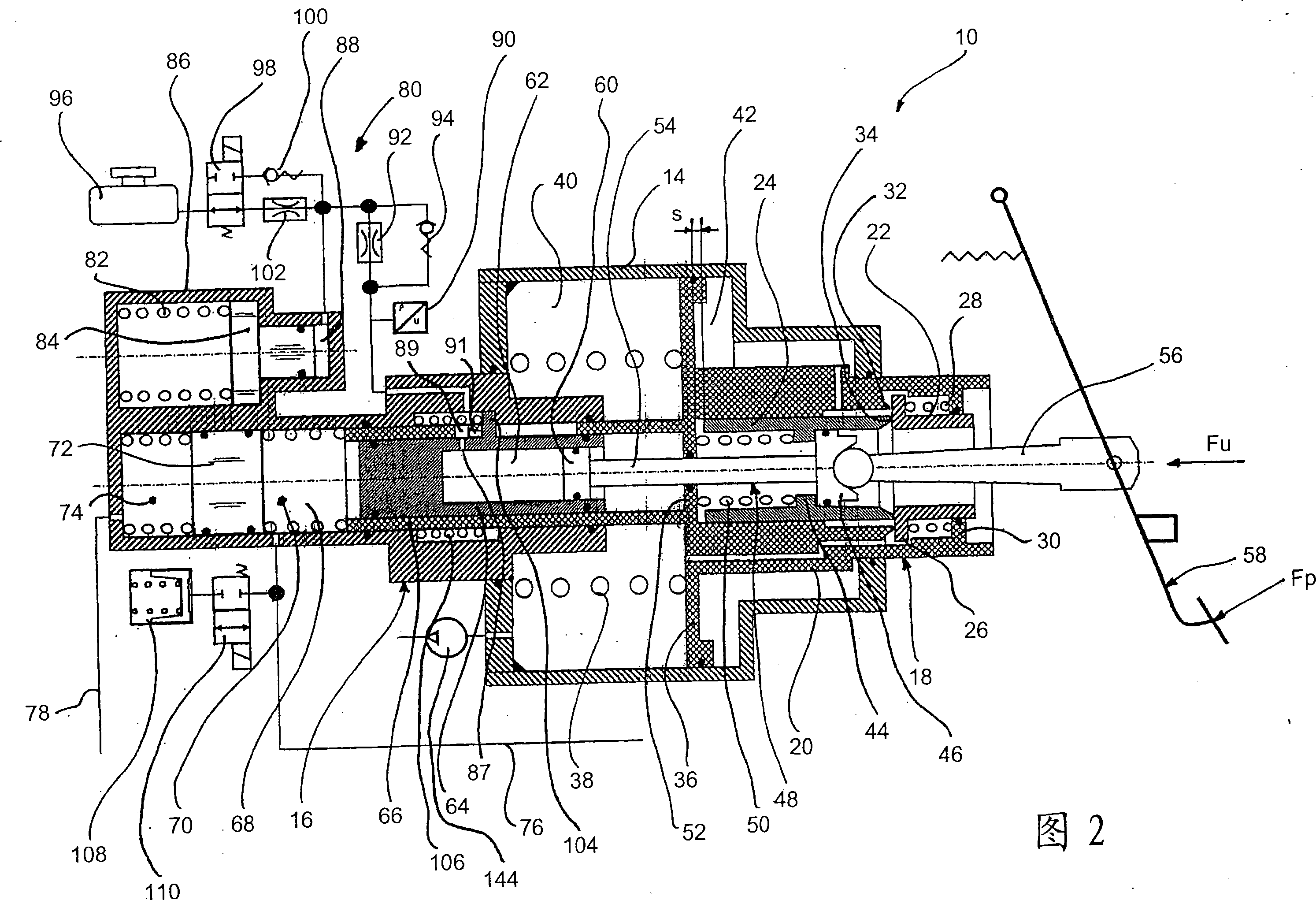

[0032] FIG. 1 shows a brake force generator according to the invention, generally designated 10 , which is integrated in a brake system 12 according to the invention. Before explaining the structure and function of the braking system according to the present invention, first, the braking force generator according to the present invention will be explained in detail.

[0033] The brake force generator according to the invention comprises a cylinder housing 14 on the left-hand side in FIG. 2 , which holds a master brake cylinder 16 and into which a control valve 18 is inserted. The control valve 18 includes a control valve housing 20 , a control valve element 22 and a valve sleeve 24 . Formed on the control valve element 22 is a flange 26 against which a pretensioning spring 28 bears. The pretensioning spring 28 is supported at the other end on a collar 30 in which the control valve element 22 is displaceably guided with a sealing effect. On the end of the flange 26 facing awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com