Speed control method during routing reversing transition course of multi-line cutting machine

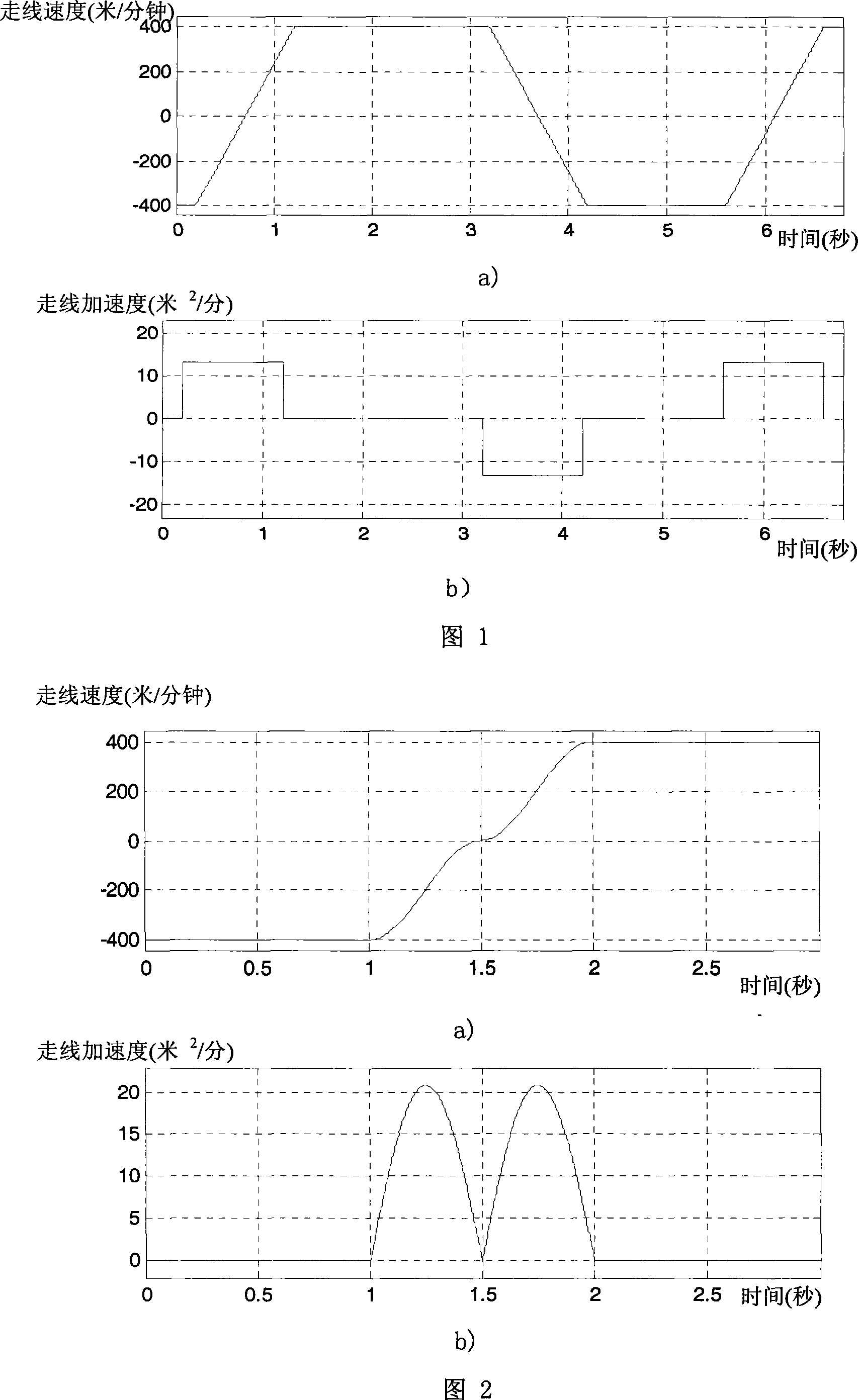

A technology of multi-wire cutting machine and transition period, which is applied in the field of speed control during the transition period of wire reversing of multi-wire cutting machine, can solve the problems of long transition time and high motor capacity requirements, and achieve short and shorten the transition time of reversing. Transition time, the effect of small speed fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

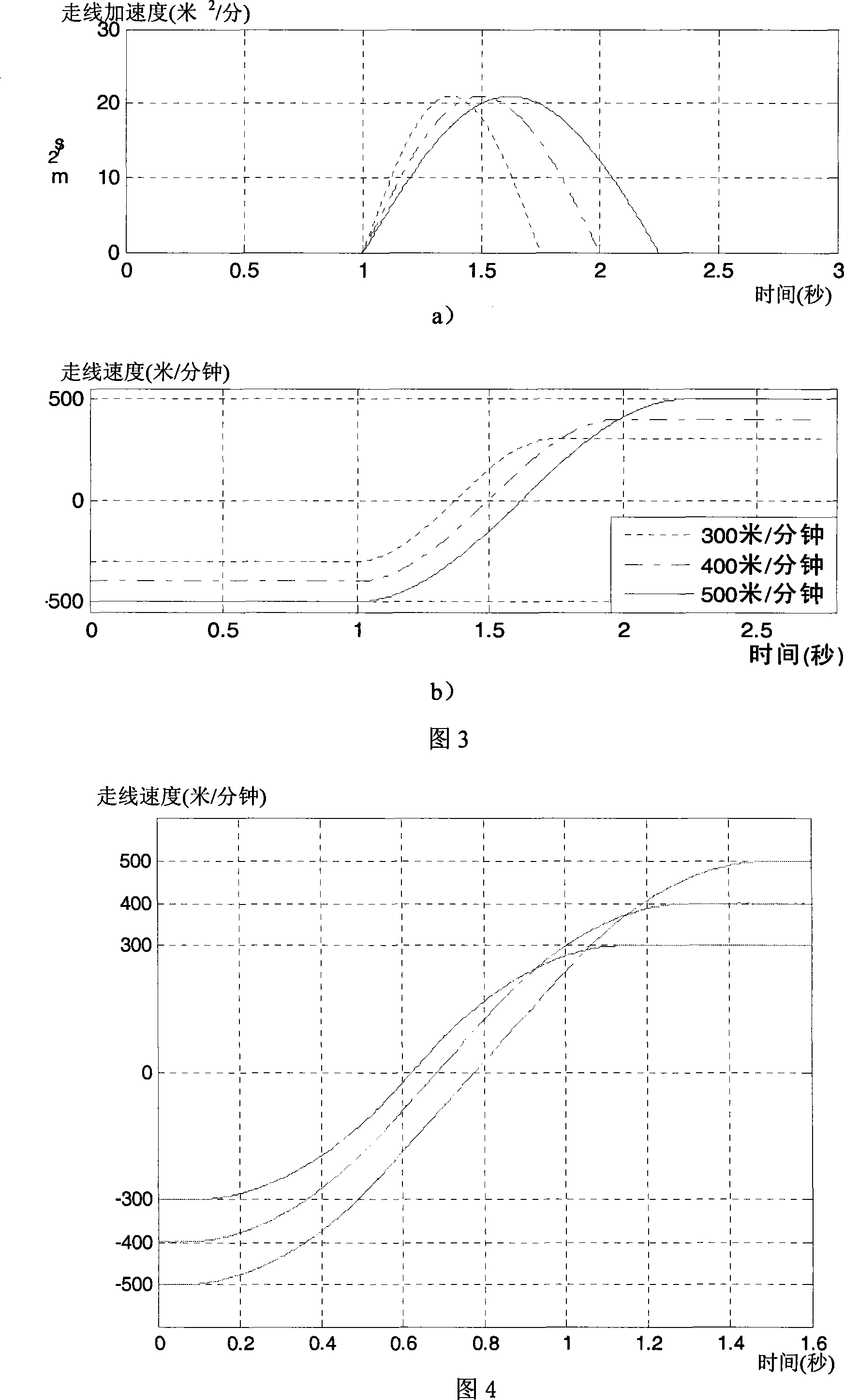

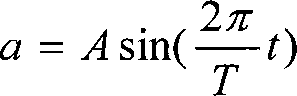

[0036] In order to meet the requirements of fast control algorithm, the MP2300 motion controller of Japan Yaskawa Company (YASKAWA) is selected as the main controller. The main controller realizes the control of the main motor through the control network based on the MECHATROLINK-II field bus. The main motor and Select SGMGH-75ACA21 and SGDS-75A12 for the servo drive respectively. First, set the transition time, the number of reciprocations per minute, and the routing speed parameters. When the routing speed is 400 m / min, the transition time T 0 , then when the speed is V, the transition time is T, then

[0037] T = V 400 T 0 - - - ( 6 )

[0038] The acceleration amplitude during the transition phase is:

[0039] A = 2 π V T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com