Working roll with consideration to strip steel convexity, edge drop control and abrasion control and using method

A technology of wear control and strip crown, which is applied in the direction of manufacturing tools, contour control, rolls, etc., can solve problems such as no crown control function, achieve stable control effect, improve the crown control of non-oriented silicon steel, and benefit Promoted app performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

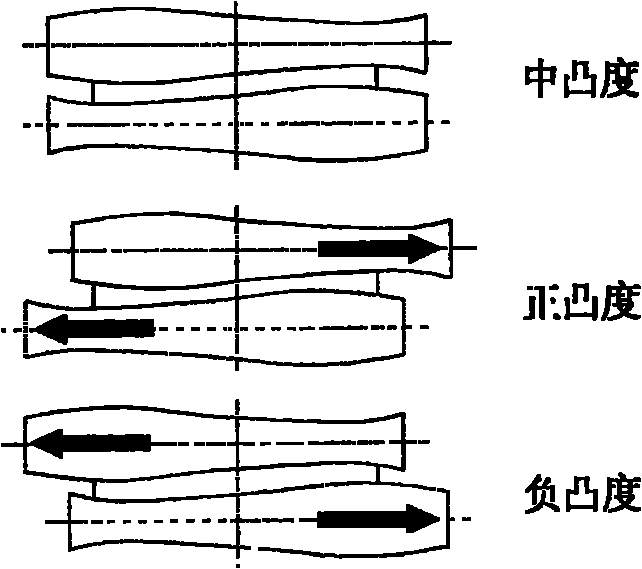

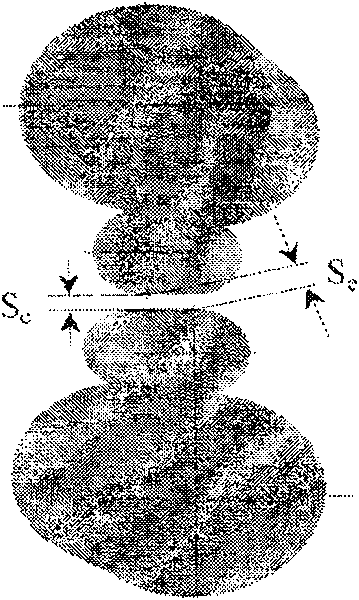

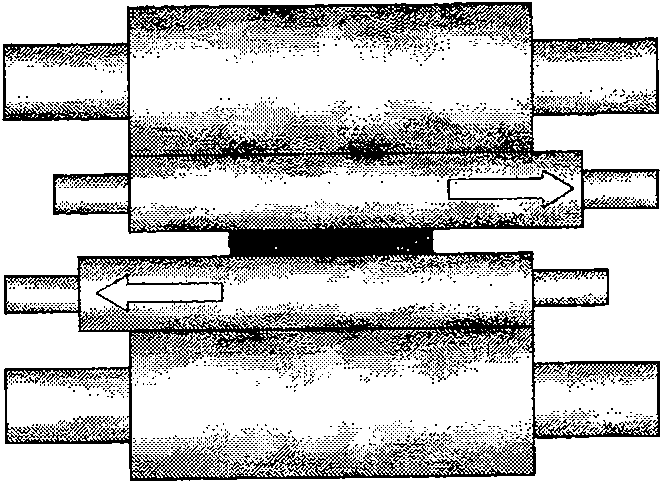

[0043] This embodiment provides a work roll that is used when rolling 2.3mm×1050mm low-grade non-oriented silicon steel with a 1700 hot continuous rolling mill, taking into account strip crown, edge drop control and wear control. 1700 hot continuous rolling mill F5 stand has a work roll body length of 2000mm and a roll body diameter range of 760mm to 700mm. The roll shape curves of the upper and lower work rolls are the same, but they are placed at an opposite angle of 180°. We call it ASR-Y here. (asymmetry self-compensating work rolls for Yrolling campaign) asymmetric self-compensating work rolls.

[0044] The above work roll is taken as an example. The ASR-Y upper work roll is composed of three parts according to the length direction, that is, the length of the crown control section L 1 , edge drop and wear control section length L 2 , the length of the structural process section L 3 (refer to Figure 4 );

[0045] The equations for determining the roll curves of each s...

specific Embodiment approach 2

[0102] Convexity control segment length L 1 Part of the roll shape curve can also adopt ordinary parabolic roll shape See Figure 7 , (see Remn-Min Guo, Characteristics of rolling mills with roll shifting, Iron and steelengineer, 1988, 65(12): 45-54) plus the hot roll shape stability component established by the hot rolling rolling unit (see Zhang Jie, Zhang Xuanli , Cao Jianguo, et al. Parameter optimization model of work roll temperature field based on genetic algorithm, Metallurgical Equipment, 2003, (4): 4-7; Ginzburg VB, High-Quality SteelRolling: Theory and Practice, Marcel Dekker, New York, 1993: 488-528) composite. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com