A method for automatic control of hot-rolled strip crown

A hot-rolled strip steel and control method technology, which is applied in the direction of contour control, etc., can solve the problems of affecting the rolling stability and the inability to guarantee the crown control accuracy of the full length of the strip steel, so as to improve the quality of the product shape and improve the convexity. The effect of degree control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

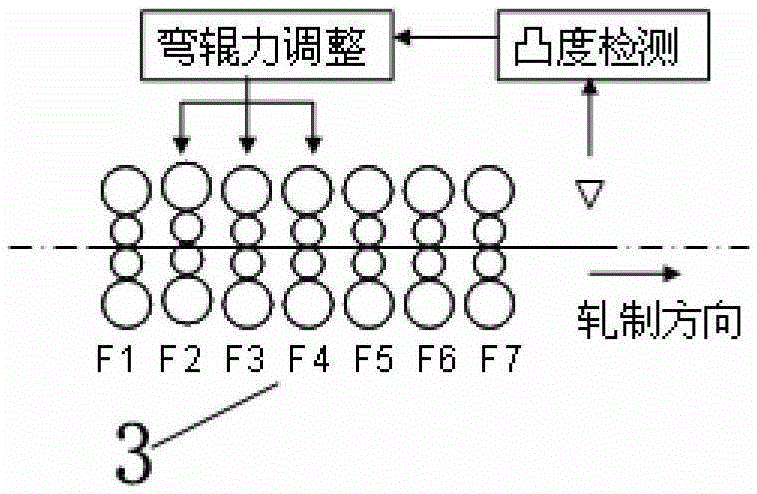

[0058] For a carbon steel product with a specification of 2*1150mm and a target convexity of 30μm (tolerance range ±20μm), the automatic convexity control method in this paper is used for production, and the control effect is as follows Figure 5 shown.

[0059] The set value of bending force of each frame and the actual value after dynamic adjustment are shown in Table 1 below. The average measured value of the final strip crown is 33 μm, reaching the target range required by the product.

[0060] Table 1 Bending force of each frame (unit: kN)

[0061] using method

Embodiment 2

[0063] For a carbon steel product with a specification of 12*1380mm and a target convexity of 40μm (tolerance range ±20μm), the automatic control method of convexity in this paper is used for production. The measured strip crown after threading is 46 μm. The set value of the bending force of each frame and the actual value after dynamic adjustment are shown in Table 2 below. The average measured value of the final strip crown is 39 μm, reaching the target range required by the product.

[0064] Table 2 Bending force of each frame (unit: kN)

[0065] using method

Embodiment 3

[0067] For stainless steel products, the specification is 6*1300mm, and the target convexity is 40μm (tolerance range ±20μm), the automatic control method of convexity in this paper is used for production. The measured strip convexity after threading is 18 μm. The set value of the bending force of each frame and the actual value after dynamic adjustment are shown in Table 3 below. The average measured value of the final strip convexity is 27 μm, reaching the target range required by the product.

[0068] Table 3 Bending force of each frame (unit: kN)

[0069] using method

[0070] According to the present invention, in the case where there is a deviation in the crown setting, the crown control accuracy of the entire length of the strip can be guaranteed, that is, in order to realize the automatic control of the crown of the hot-rolled strip, the uniformity of the crown of the strip can be guaranteed, and at the same time Avoid affecting rolling stability.

PUM

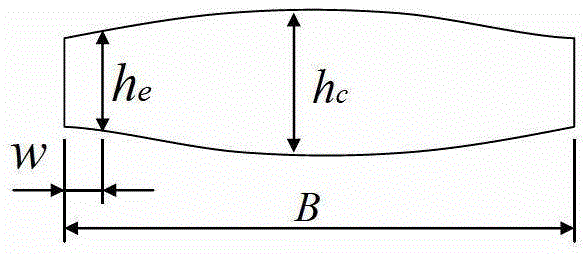

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com