Operation panel, elevator using the operation panel, and method of taking out intermediate panel of the operation panel

A technology for the middle panel and operation panel, which is applied in the direction of elevators, transportation and packaging, etc., and can solve problems such as difficulty in holding by hand, installation of the middle panel 12, setting gaps between the side panels 6 and the middle panel 12, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

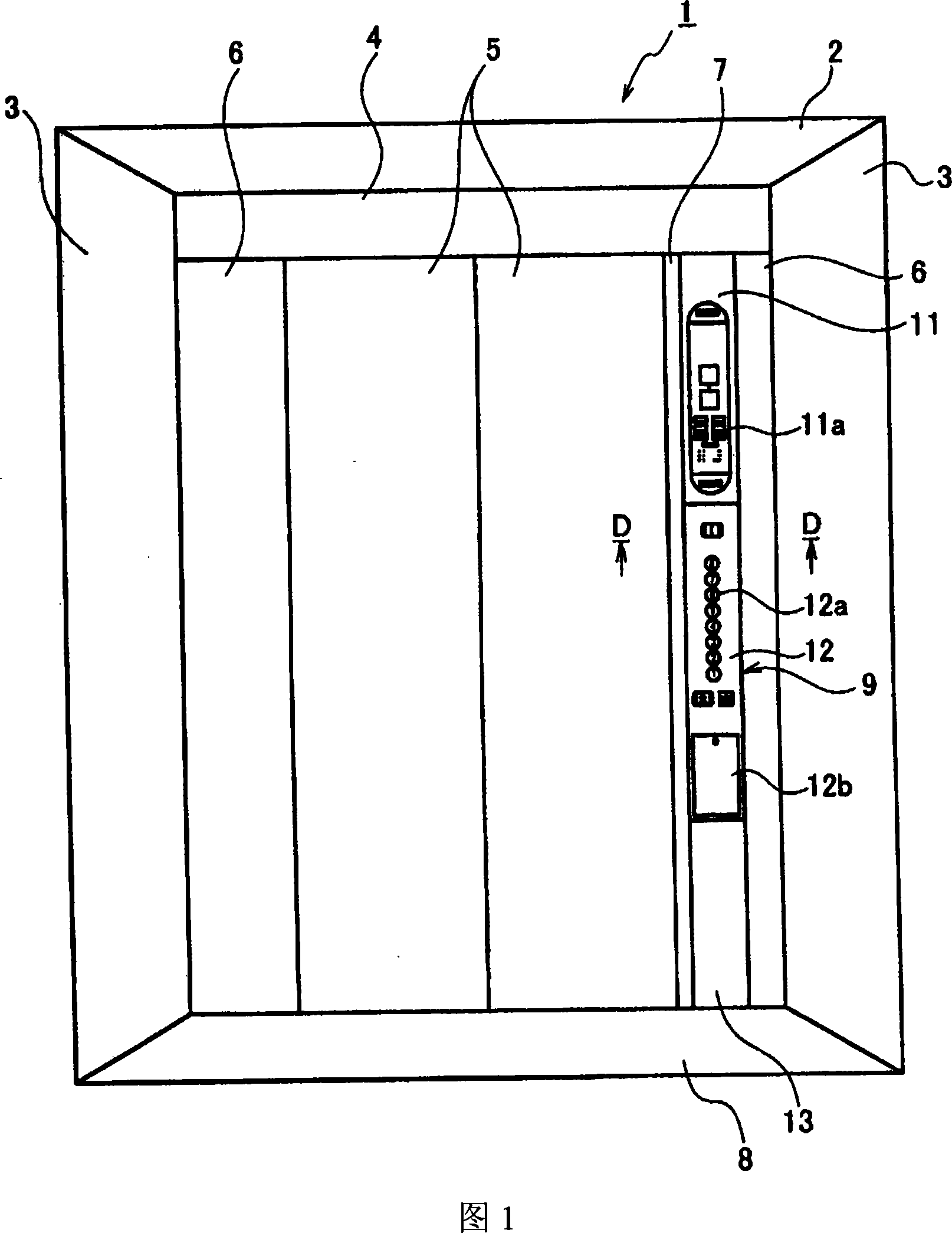

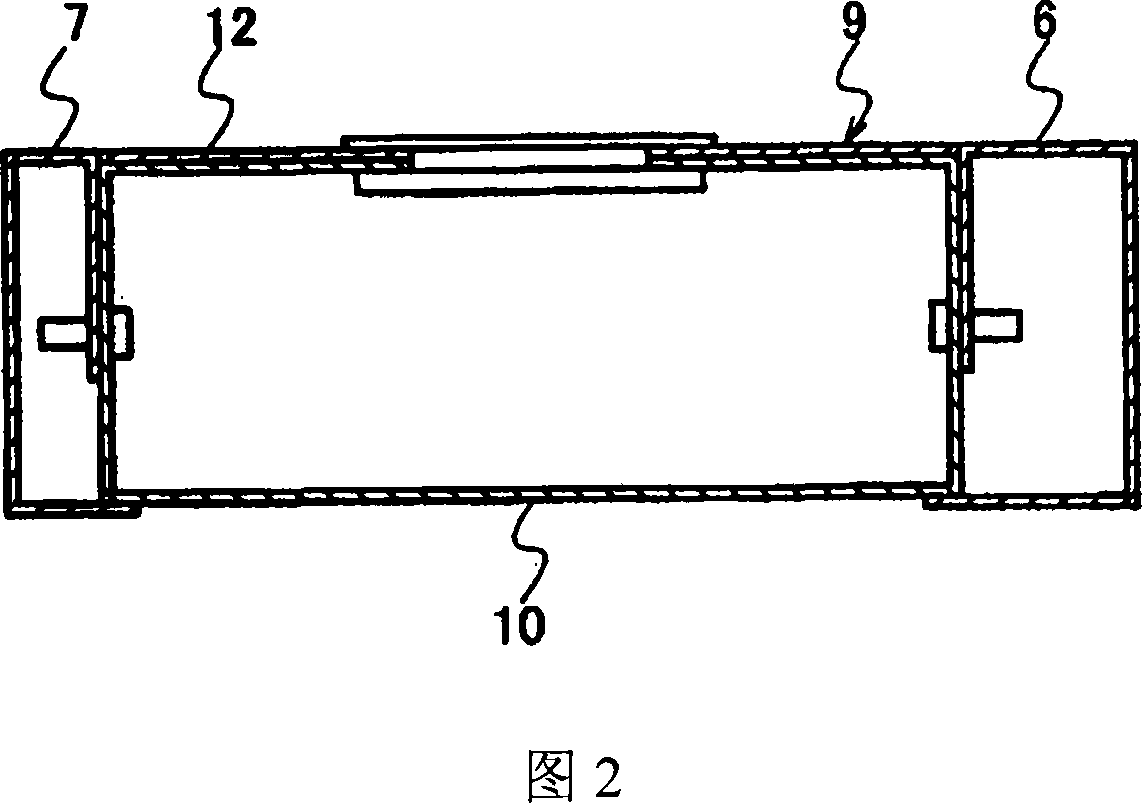

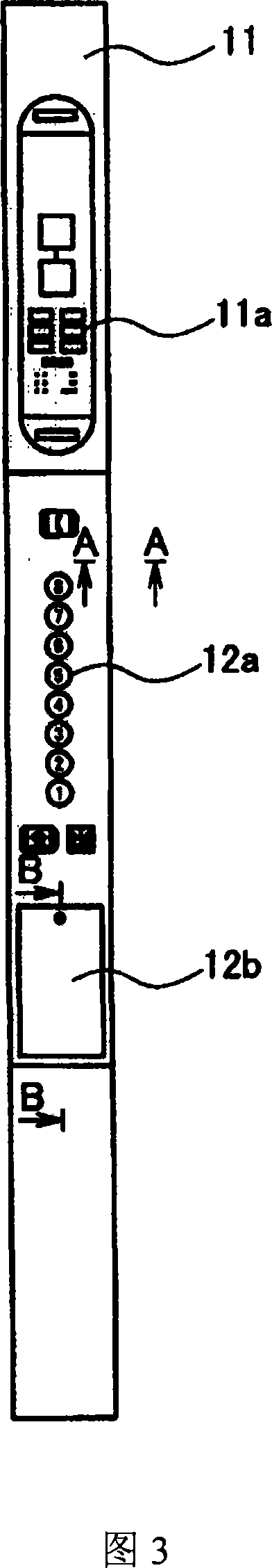

[0029] Fig. 3 is a front view of the operating panel in the car of the first embodiment of the present invention, Fig. 4A, Fig. 4B, Fig. 4C and Fig. 4D are perspective views of the operating panel in the car of Fig. 3, and Fig. 5 is the A-A line of Fig. 3 Sectional view, Fig. 6 is a view obtained from viewing the hinge unit from below, Fig. 7A, Fig. 7B, Fig. 7C and Fig. 7D are side sectional views of the first embodiment, Fig. 8 is a sectional view along line B-B of Fig. 3 , Fig. 9 is a view from below Transverse section view with the middle panel open.

[0030] In this embodiment, the same symbols are assigned to the same or similar parts as those of the above-mentioned conventional example, and repeated explanations are omitted.

[0031] In FIG. 3 , the upper panel 11 is fixed to the box body 10 (see FIG. 4 ) with screws. As shown in Figure 4A, Figure 4B, Figure 4C and Figure 4D, a pair of upper and lower hinge units 14 are arranged in the box body 10, and these hinge units...

no. 2 example

[0042] Next, a second embodiment of the present invention will be described. Fig. 10 is a view of the hinge unit of the second embodiment seen from below. In each of the following embodiments, parts identical or similar to those of the first embodiment are assigned the same symbols, and repeated descriptions are omitted.

[0043] In this embodiment, the socket hinge 15 and the flat hinges 16 and 17 of the hinge unit 14 are integrated. In this way, compared with the case where the socket hinge 15 and the flat hinges 16, 17 are welded together as in the first embodiment, the thickness at the time of folding can be reduced, so that the operation panel can be further thinned.

no. 3 example

[0045] A third embodiment of the present invention will be described below. 11A, 11B, 11C and 11D are side cross-sectional views of the third embodiment.

[0046] In this embodiment, the lower end of the rod 23 is pivotally connected to the box body 10 through a pin 22 extending transversely (orthogonal to the paper plane of FIG. 11 ). In addition, the connecting member 25 is pivotally connected to the upper end of the rod 23 through a pin 24 extending laterally, and the support shaft 25 a protrudes vertically upward from the upper end of the connecting member 25 .

[0047] The bearing 26 is mounted on the upper part of one side of the back of the middle panel 12, and the bearing 26 has a top wall 26a protruding rearward from the upper end. A through hole is formed in the top wall 26a, and the support shaft 25a is rotatably penetrated through the through hole.

[0048] During maintenance and overhaul, the screws 21 for fixing the middle panel 12 are removed from the state sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com