One-sided electrode with reduced twisting for a secondary battery, and method for producing same

A secondary battery and electrode technology, applied in the field of single-sided electrodes and their preparation, can solve problems such as limiting battery performance and increasing costs, and achieve the effects of improving productivity, avoiding curling, and improving work convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

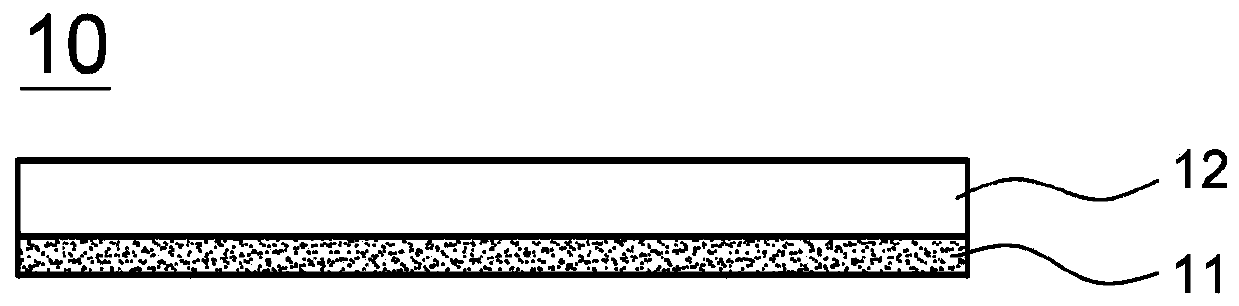

[0088] A clad metal (8μm+12μm) containing copper and stainless steel was prepared. Thereafter, the electrode paste (by LiNi 0.55 mn 0.30 co 0.15 o 2 , Denka black as a conductive material and polyvinylidene fluoride as a binder were mixed in a weight ratio of 96:2:2 and then NMP was added) were coated on the composite metal to have a thickness of 200 μm. Then, it is dried and rolled to produce a single-sided electrode sheet.

Embodiment 2

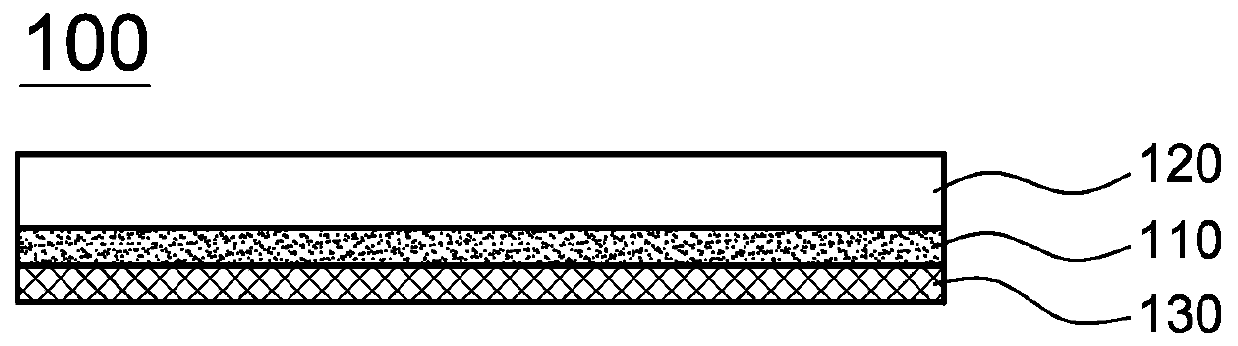

[0090] A stainless steel having a thickness of 12 μm was laminated on one side of a copper foil having a thickness of 8 μm as a current collector, and then heat and pressure were applied to form an electrode deformation preventing layer. Then the electrode paste (by LiNi 0.55 mn 0.30 co 0.15 o 2 , Denka black as a conductive material and polyvinylidene fluoride as a binder were mixed in a weight ratio of 96:2:2 and then NMP was added) were coated on the other side of the copper foil to have a thickness of 200 μm. Then, it was dried and rolled to prepare a single-sided electrode sheet.

Embodiment 3

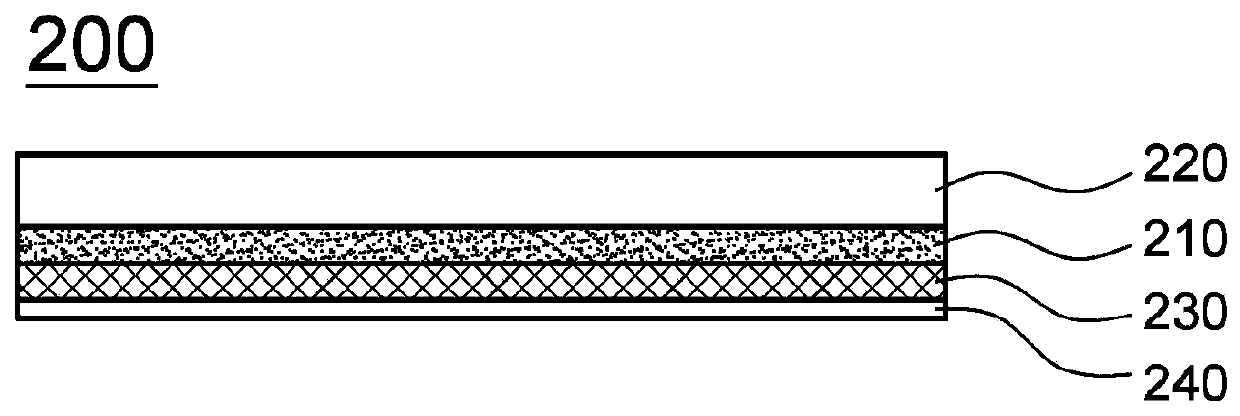

[0092] The polypropylene solution was coated onto a copper foil having a thickness of 8 μm as a current collector to have a thickness of 12 μm, and dried to form an electrode deformation preventing layer. Thereafter, the electrode paste was coated so as to have a thickness of 40 μm, followed by drying and rolling to prepare a single-sided electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com