Isothermal treatment method for nodular cast iron bainite

A nodular cast iron, isothermal treatment technology, applied in the field of temperature treatment, can solve the problems of consuming manpower, material resources and time, unstable isothermal temperature, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

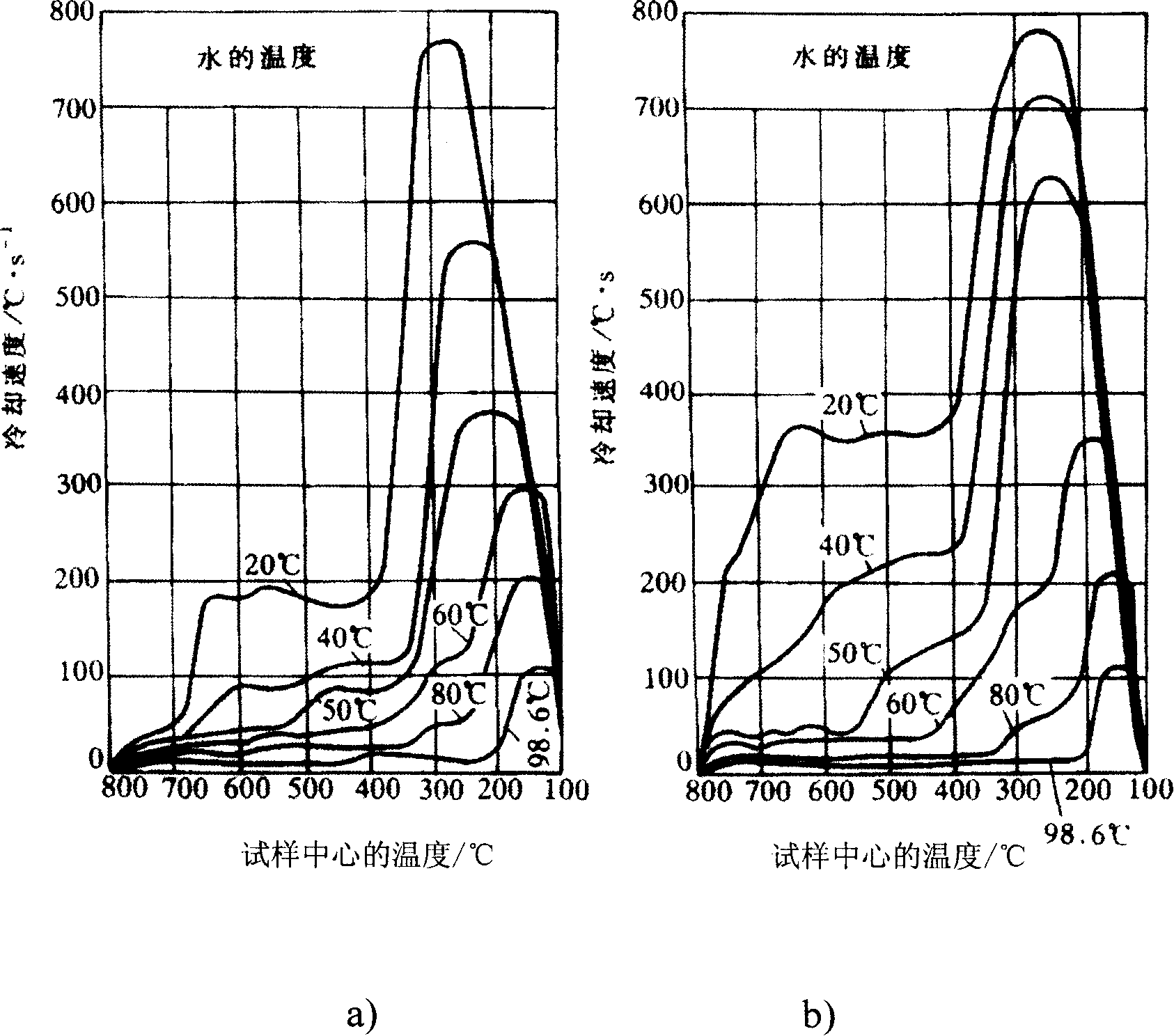

Image

Examples

Embodiment 1

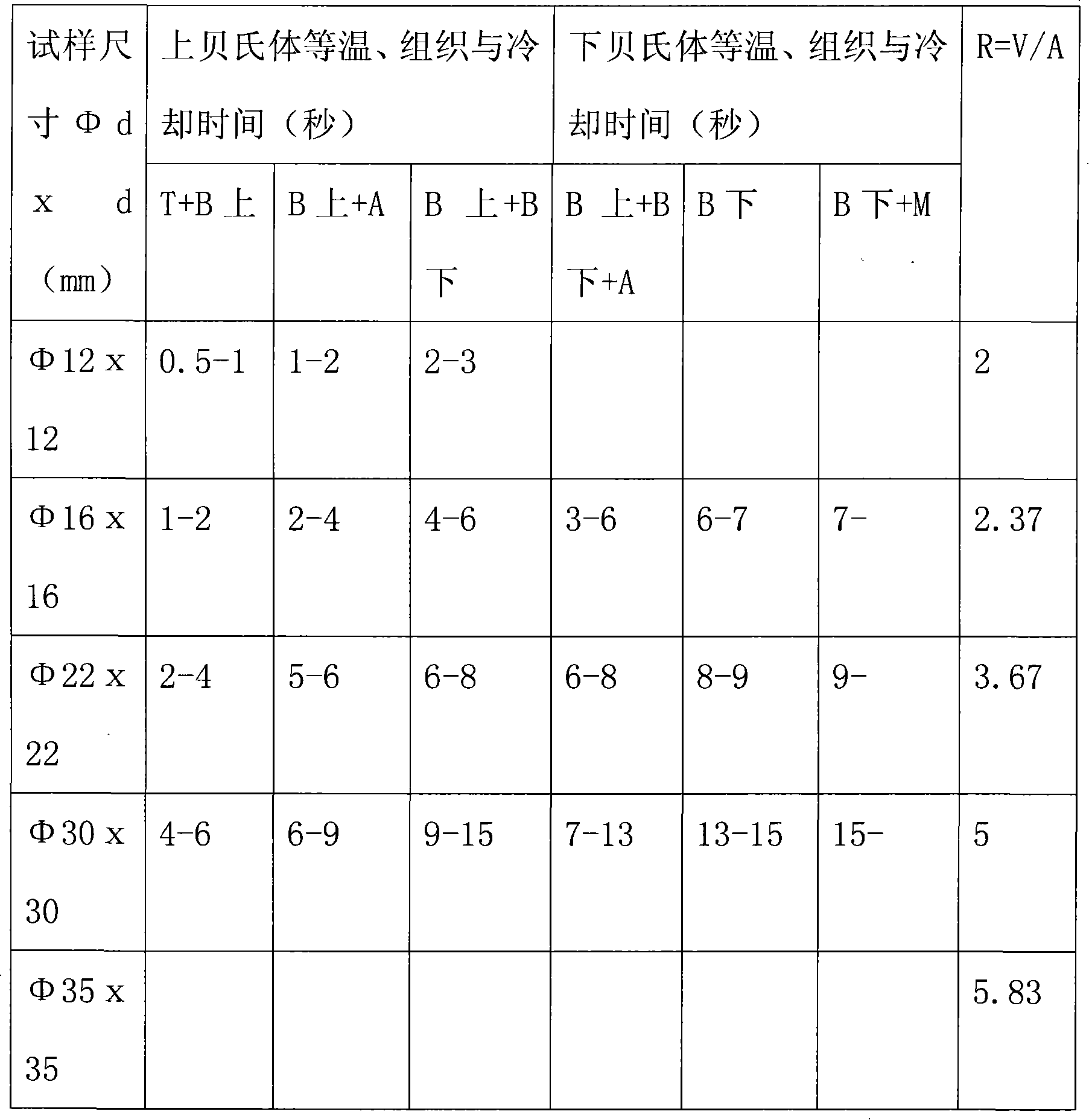

[0073] Embodiment 1. basic process data table example

[0074] Table 1 Basic cooling water temperature T 0 =Basic process data table at 30℃

[0075]

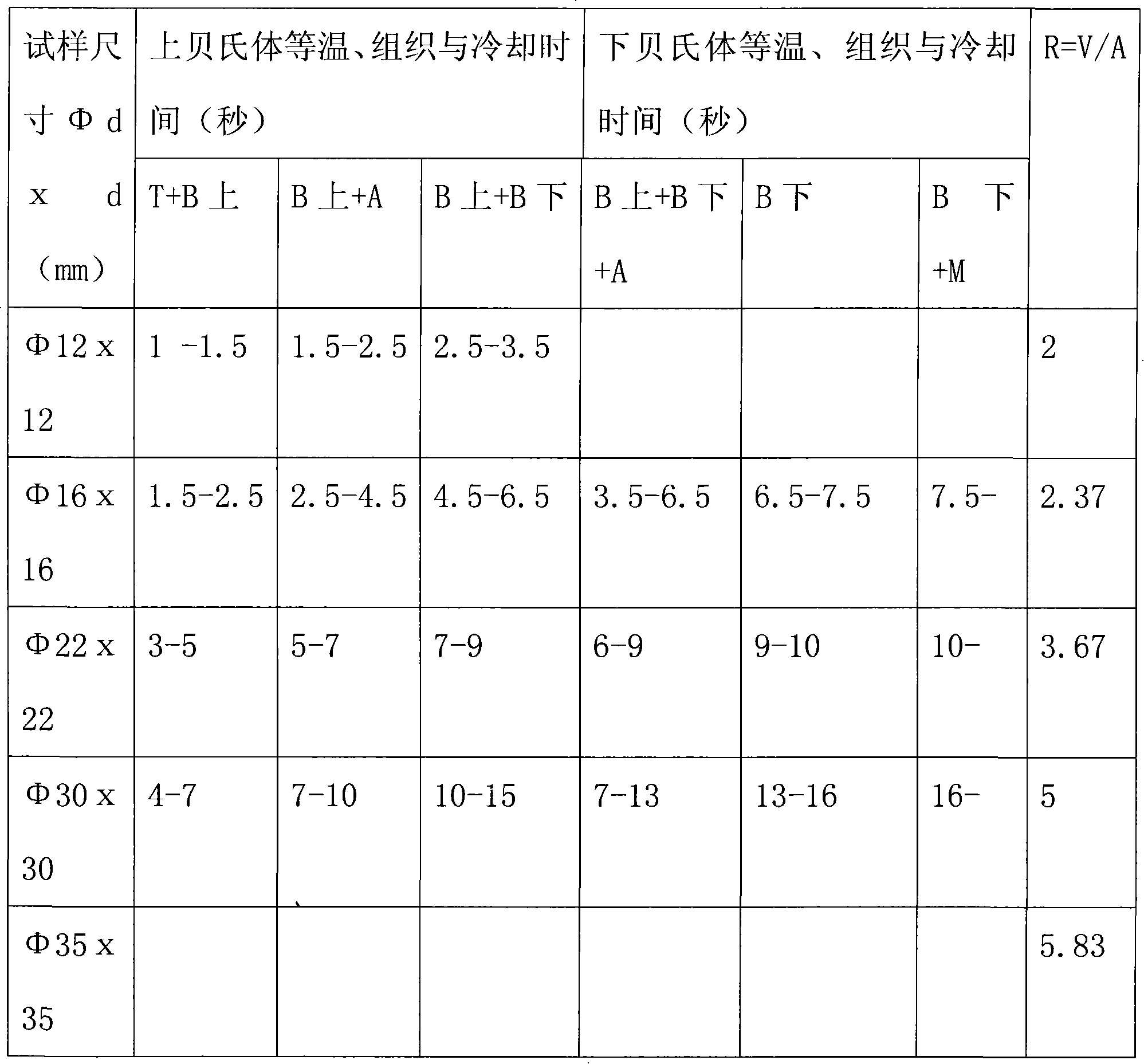

[0076] Table 2 Basic process data table for practical cooling water temperature T=40°C

[0077]

Embodiment 3

[0078] Embodiment 3. Controlled cooling process parameter search example

[0079] The size of a workpiece to be processed is Φ16×100mm to calculate R=3.70; look up table 1, the basic standard workpiece with a basic size of Φ22×22 (mm) has R=3.67. The cooling parameters R of the two are very similar, so the process parameters of Φ22×22 (mm) can be used to control the cooling treatment of a workpiece to be processed.

Embodiment 4

[0080] Example 4.T 0 , t, n 0 Examples of relevant process data sheets

[0081] Table 3T 0 , t, n 0 Process data sheet (measured)

[0082] Sample size

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com