Automatic testing and emendation system and method for finished circuit board

A finished circuit board, automatic testing technology, applied in electronic circuit testing and other directions, can solve problems such as slow testing process, laborious data recording, and a large number of transfer switches, and achieve the effects of convenient debugging, convenient operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

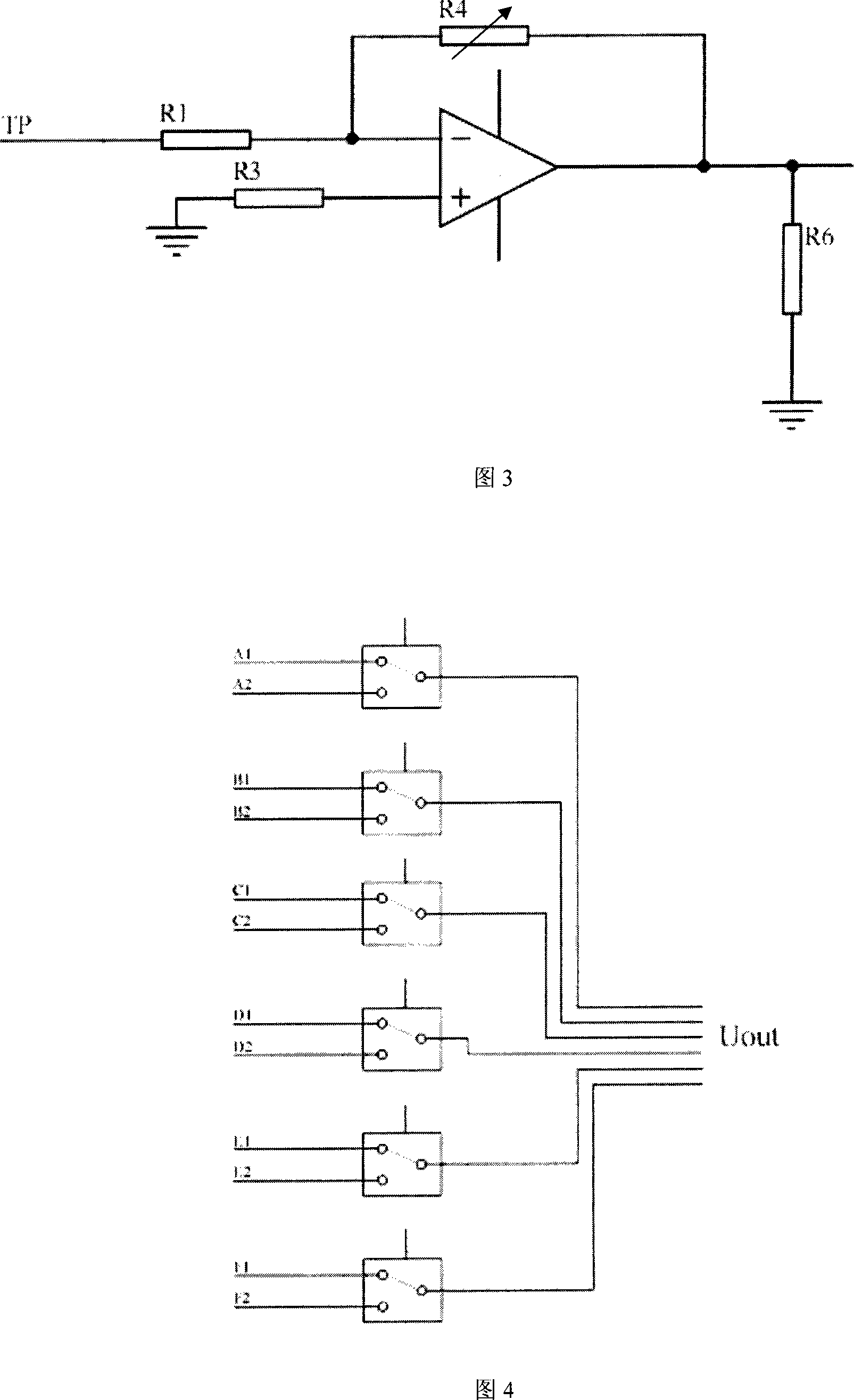

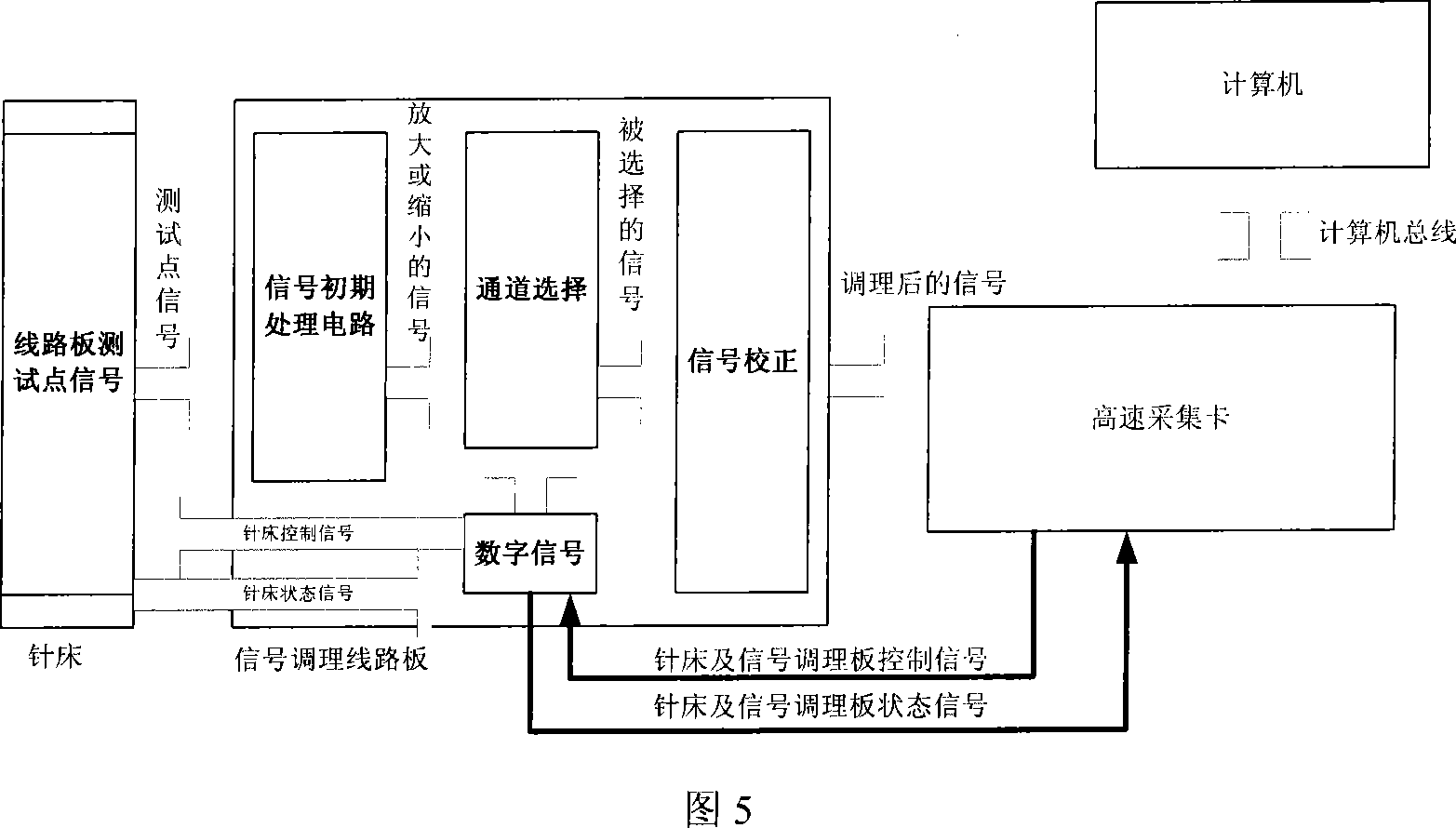

Method used

Image

Examples

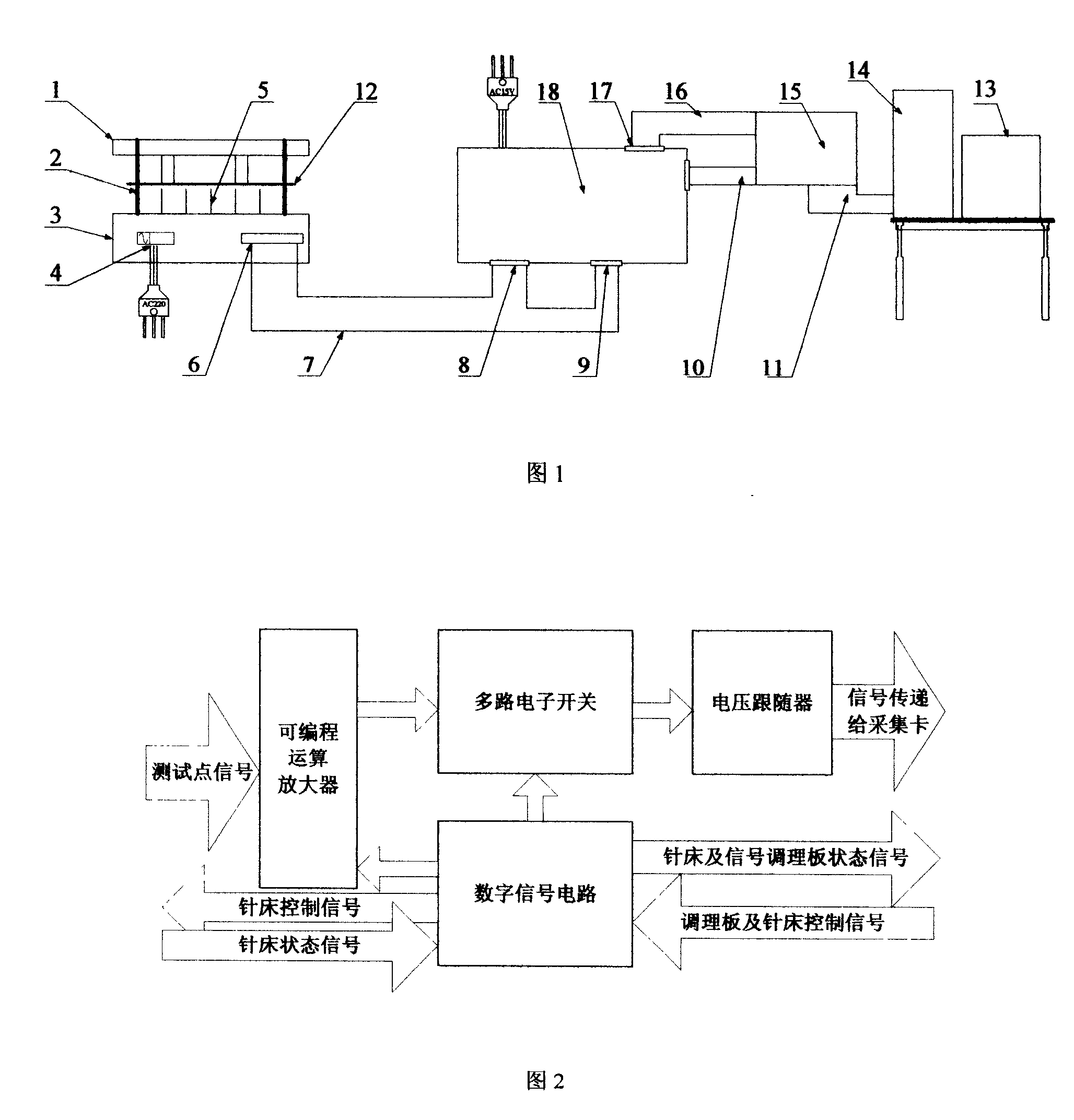

Embodiment 1

[0035] This embodiment takes the PCBA test of the electric welding machine industry as an example. The computer adopts the products of Taiwan Advantech Technology Co., Ltd. The detailed parameters are as follows:

[0036] Computer (industrial computer):

[0037] PCA-6006LV motherboard

[0038] PCA-6113P4 base plate

[0039] Intel Pentium4 2.4GHz CPU

[0040] Kingston 256M DDR memory

[0041] Seagate 80G IDE hard drive (7200 rpm)

[0042] Asus DVD drive

[0043] D-Link 100M network card

[0044] 250W industrial power supply

[0045] Data acquisition control card model: PCL-1800, a 330KHz high-speed multi-function data acquisition card. The detailed parameters are as follows:

[0046] 12-bit A / D, 330KS / s sampling rate

[0047] 1K sampling FIFO

[0048] 16 single-ended or 8 differential inputs

[0049] 2-way 12-bit D / A (one with DMA)

[0050] 16-way DIO and a 16-bit counter

[0051] Analog trigger function

[0052] 16 analog watchdogs for analog trigger

[0053] As ...

Embodiment 2

[0078] This embodiment takes the most common KR circuit board in the electric welding machine industry as an example.

[0079] Put the KR series PCBA into the needle bed, clamp the tooling, check the connection and power on;

[0080] Start the computer, run the data collection and processing program, input the name of the tester and the PCBA model, and after confirmation, perform a series of initializations and enter the waiting state;

[0081] Click "Start Collection", the system starts to collect the information of each point, and displays it on the screen after proper processing. If no calibration is required, click Save and the test ends.

[0082] This embodiment has been tested and has the following characteristics:

[0083] 1. High test and correction efficiency: give full play to the advantages of the powerful acquisition and control functions of the software and data acquisition control card, collect the signals of each test point through the needle bed, send them to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap