A detection and analysis method and system for a DC micro-motor product

An analysis method and micro-motor technology, applied in the measurement of current/voltage, measurement device, measurement of electrical variables, etc., can solve the problems of high labor intensity, low production efficiency, inaccurate results, etc., to improve the level of automation and realize automatic Adjust and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

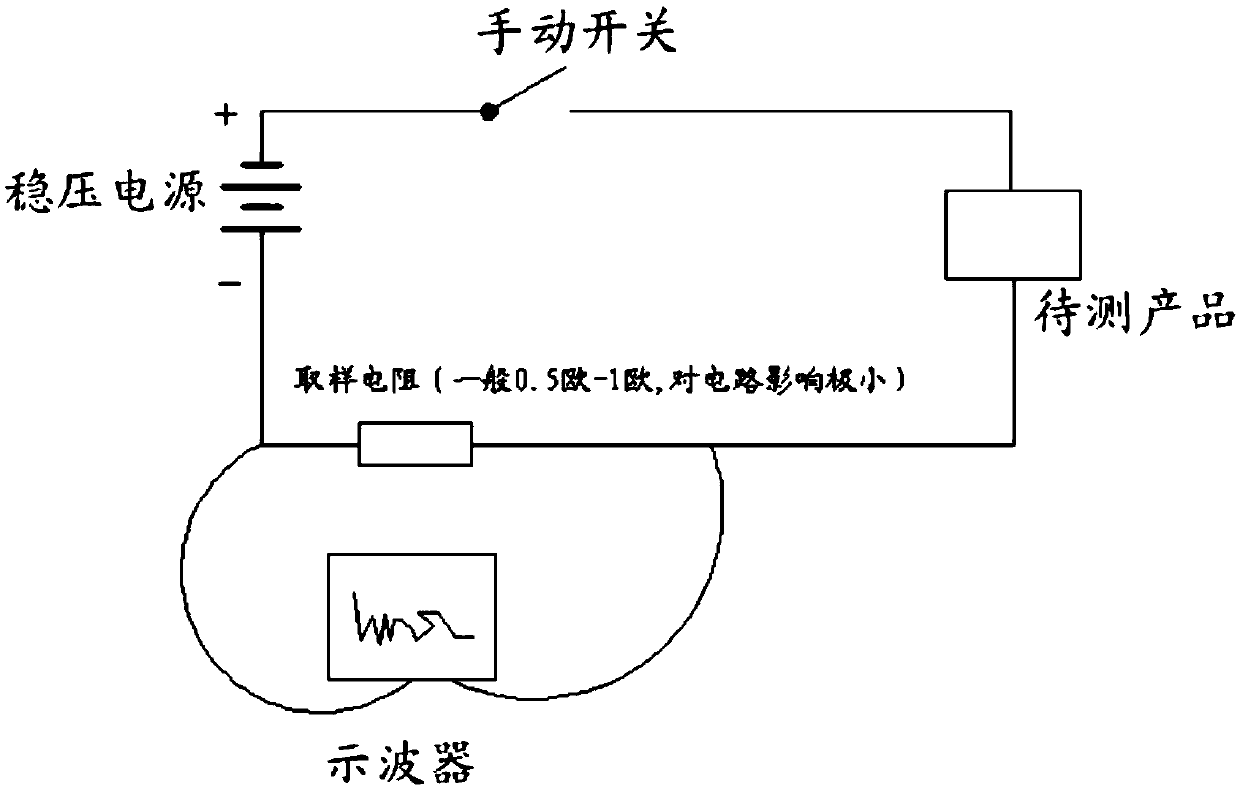

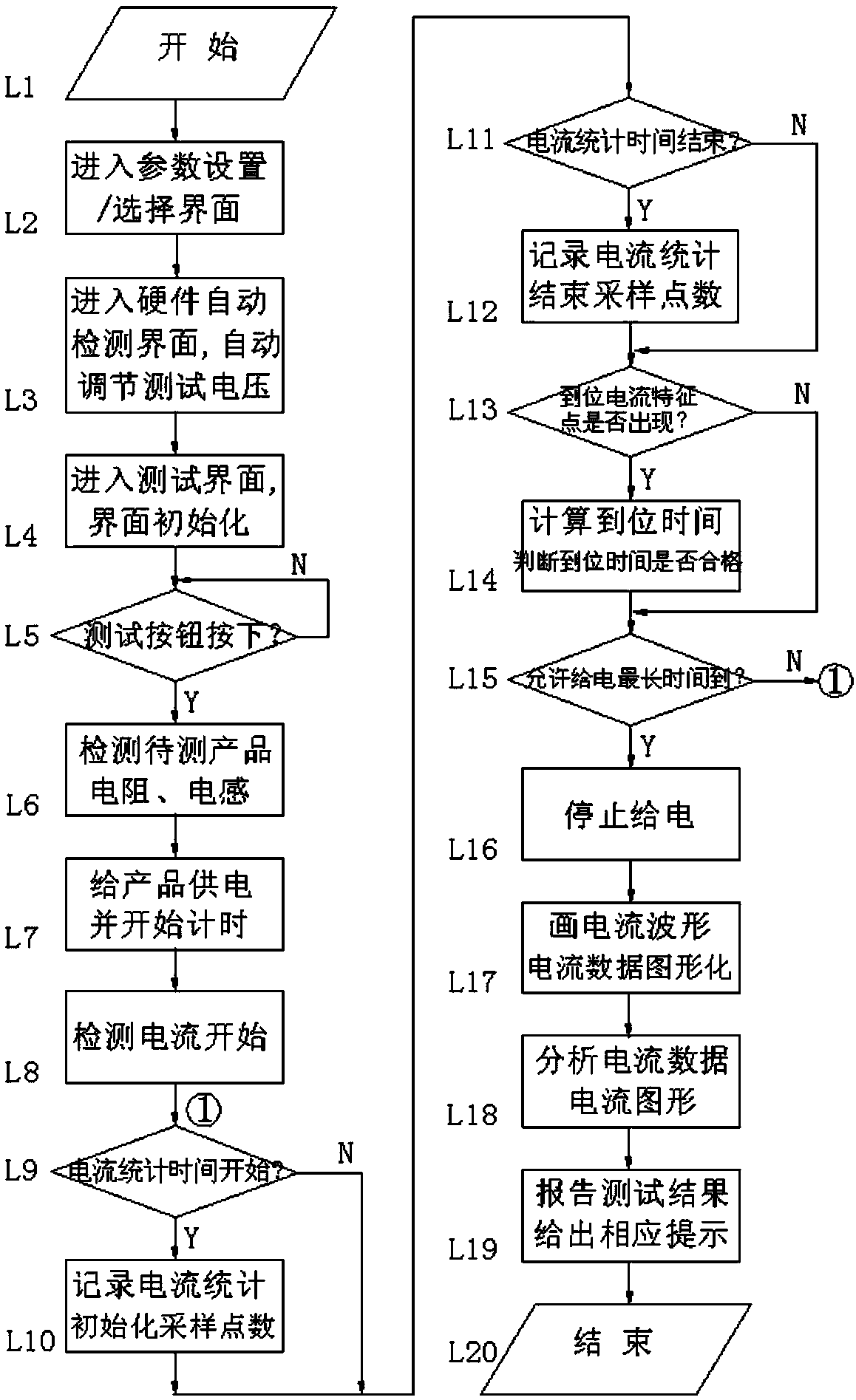

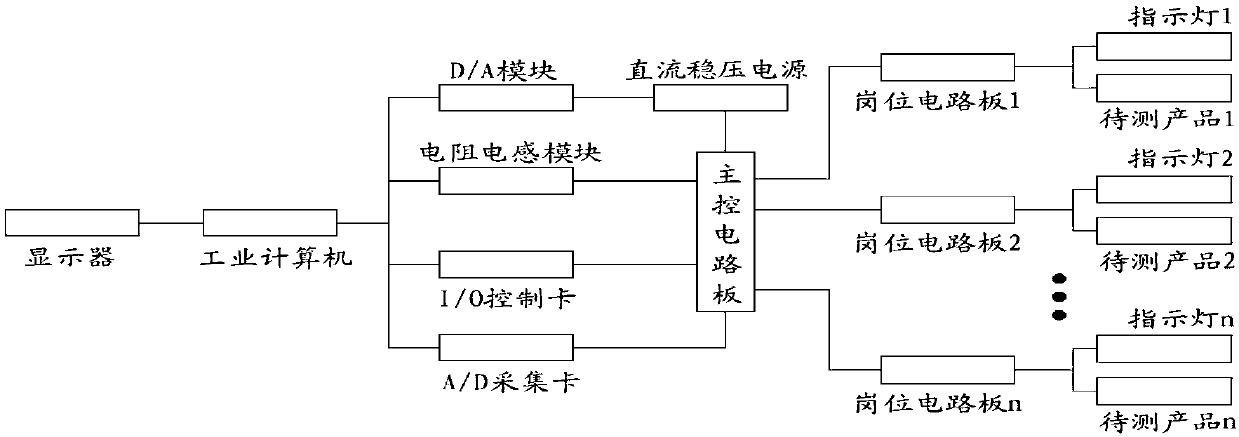

[0079] See figure 1 — Figure 12 , a detection and analysis method for a DC micro-motor product, the steps are as follows:

[0080] L1: start;

[0081] L2: Enter the parameter setting / selection interface;

[0082] L3: Enter the hardware automatic detection interface, automatically adjust the test voltage

[0083] In order to improve the automation of the equipment, the test program can automatically detect the hardware and automatically adjust the test voltage. If the hardware self-test fails, a maintenance message will pop up. After the hardware self-test is normal, it will automatically enter the test interface;

[0084] L4: Enter the test interface, interface initialization

[0085] Initialize the test interface to prepare for the test;

[0086] L5: Test if the button is pressed

[0087] The program waits for the tester to press the test button. After the test button is pressed, the program starts to test the product;

[0088] L6: Detect the resistance and inductance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com