Production method for nano focusing X ray lens combination

A combined lens and nano-focusing technology, which is applied in the field of X-ray microstructured optical devices, can solve the problems of poor light-gathering ability, high roughness, and low X-ray radiation transmittance of the combined lens, so as to improve the radiation transmittance, The light-gathering ability is improved, and the effect of increasing the light-gathering aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

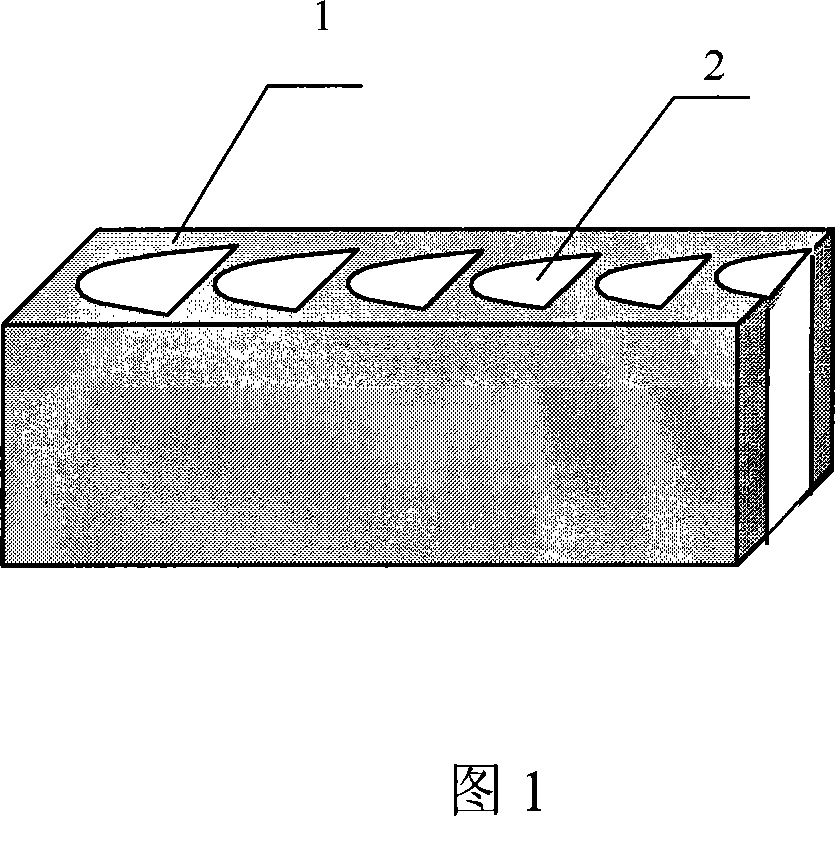

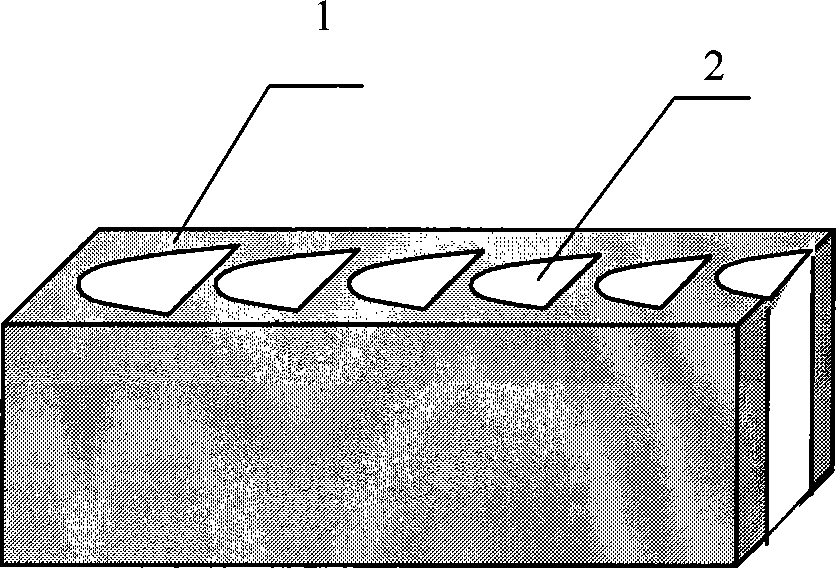

[0024] Refer to attached figure 1 , a method of manufacturing a silicon material one-dimensional nano-focus X-ray composite lens, the steps are as follows:

[0025] (A) use electron beam etching technology to make a photolithographic mask plate of glass substrate metal chromium material, the photolithographic mask pattern is composed of a plurality of combined lens refraction units coaxially arranged in sequence, and the refraction unit is composed of The through-hole-shaped air gap is formed together with the lens main body material. The cross-sectional shape of the air gap is elliptical, and the maximum diameter of the air gap corresponding to the minor axis of the ellipse is smaller than the minor axis of the ellipse. The elliptical air gap of the lens unit The long axis of the gap is on the same straight line, and the size of the ellipse corresponding to the air gap gradually decreases, and they are arranged in order from large to small;

[0026] (B) Carry out conventiona...

Embodiment 2

[0034] In the technical scheme of the present embodiment, the thickness of the ultraviolet negative photoresist in the step (C) is 1 micron, and the thickness of the aluminum metal film described in the step (E) is 150 nanometers, and the total depth in the step (G) The etching time of silicon is 30 minutes, the etching phase lasts 6 seconds, the gas SF 6 Injection rate 130 sccm, working pressure 2.4 Pa, working power 600 watts, deposition phase duration 5 seconds, gas C 4 f 8 The injection rate is 120sccm, the working pressure is 1.9 Pa, and the working power is 600 watts, and the rest are the same as in Example 1.

Embodiment 3

[0036] In the technical scheme of the present embodiment, the thickness of the ultraviolet negative photoresist in the step (C) is 3 microns, and the thickness of the aluminum metal film described in the step (E) is 200 nanometers, and the total depth in the step (G) The etching time of silicon is 40 minutes, the duration of etching phase is 6.5 seconds, the gas SF 6 The injection rate is 135 sccm, the working pressure is 2.5 Pa, the working power is 610 W, the duration of the deposition phase is 5.5 seconds, and the gas C 4 f 8 The injection rate is 125 sccm, the working pressure is 2.0 Pa, and the working power is 610 watts, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com