Production for aluminium-material X-ray assembled lens

A technology for combining lenses and manufacturing methods, which is applied in the directions of lenses, radiation/particle processing, photolithographic process exposure devices, etc., can solve the problems of large absorption of X-ray radiation, large spherical aberration, etc., and achieves increased light collection aperture and small material restrictions. , The effect of easy beam alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

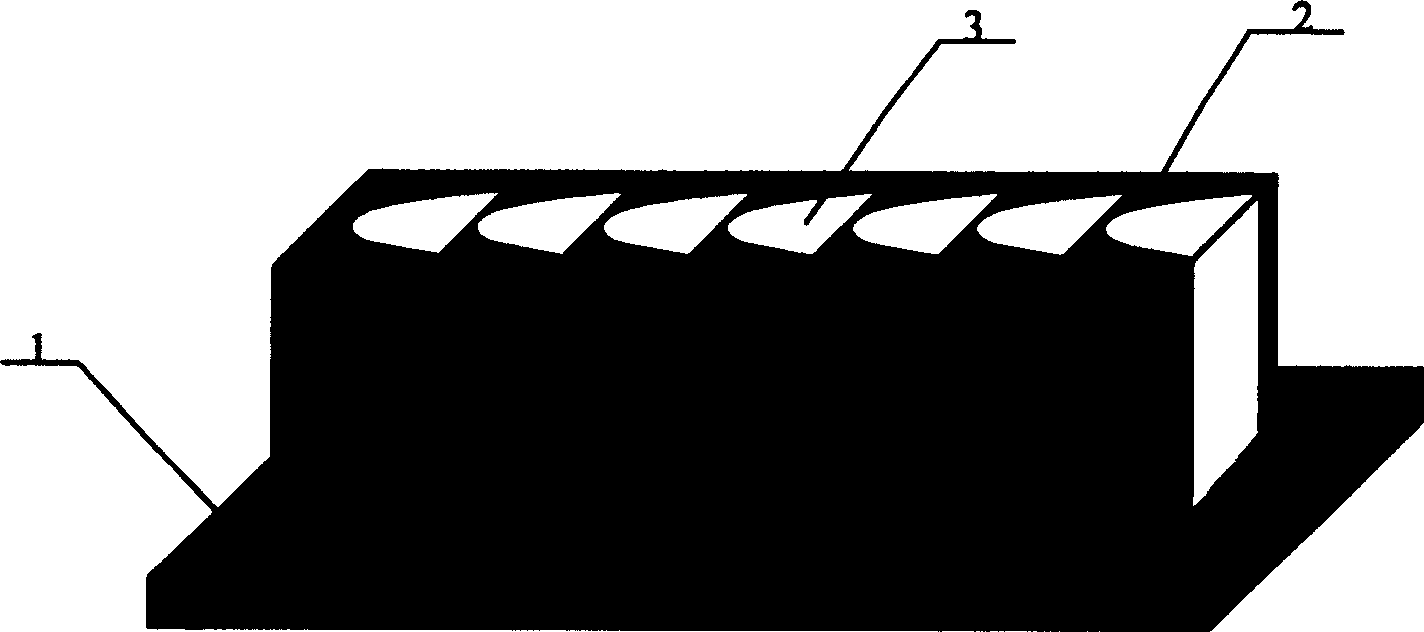

[0029] Refer to attached figure 1 , a kind of manufacture method of aluminum material parabolic X-ray compound lens, comprises the preparation of X-ray lithography mask, the preparation of X-ray lithography substrate and the formation of final aluminum material lens; (1) X-ray lithography mask The preparation includes the following steps:

[0030] (A) Spin-coating a layer of polyimide coating on the surface of the silicon substrate through conventional cleaning treatment, baking and curing;

[0031] (B) growing an electroformed cathode film of a copper material on the surface of the solidified sample sheet;

[0032] (C) Coating a layer of AZP4000 photoresist on the surface of the electroformed cathode film, carrying out photoetching, development, and hardening of the above photoresist to form a photoresist pattern structure;

[0033] (D) growing one deck metal thin film on photoresist pattern structure, described metal thin film material is gold, and its thickness is less th...

Embodiment 2

[0045] In the technical scheme of the present embodiment, the metal material electroforming cathode film described in the step (B) is a titanium material, and the thickness of the PMMA coating on the surface of the titanium sheet is 1000 microns in the step (1), and all the other steps are the same as in Example 1.

Embodiment 3

[0047] In the technical scheme of the present embodiment, the metal material electroforming cathode film described in the step (B) is a nickel material, and the thickness of the PMMA coating on the surface of the titanium sheet is 2000 microns in the step (1), and all the other steps are the same as in Example 1.

[0048] Process tests have been carried out on the above three embodiments, and it can be seen from the test results that they all meet the requirements of the structural shape and size of the X-ray combined lens, and the process test effect of embodiment 2 is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com