Display device manufacturing device and display device manufacturing method

A technology for a display device and a manufacturing device, which is applied in the directions of identification devices, instruments, optics, etc., can solve the problems of deterioration of the quality of the display device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

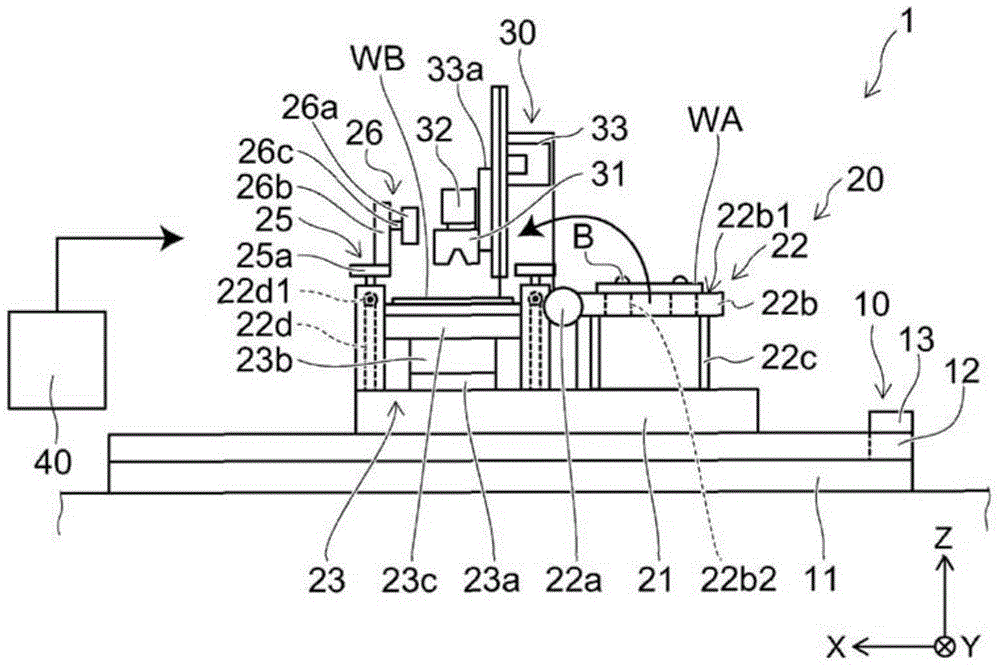

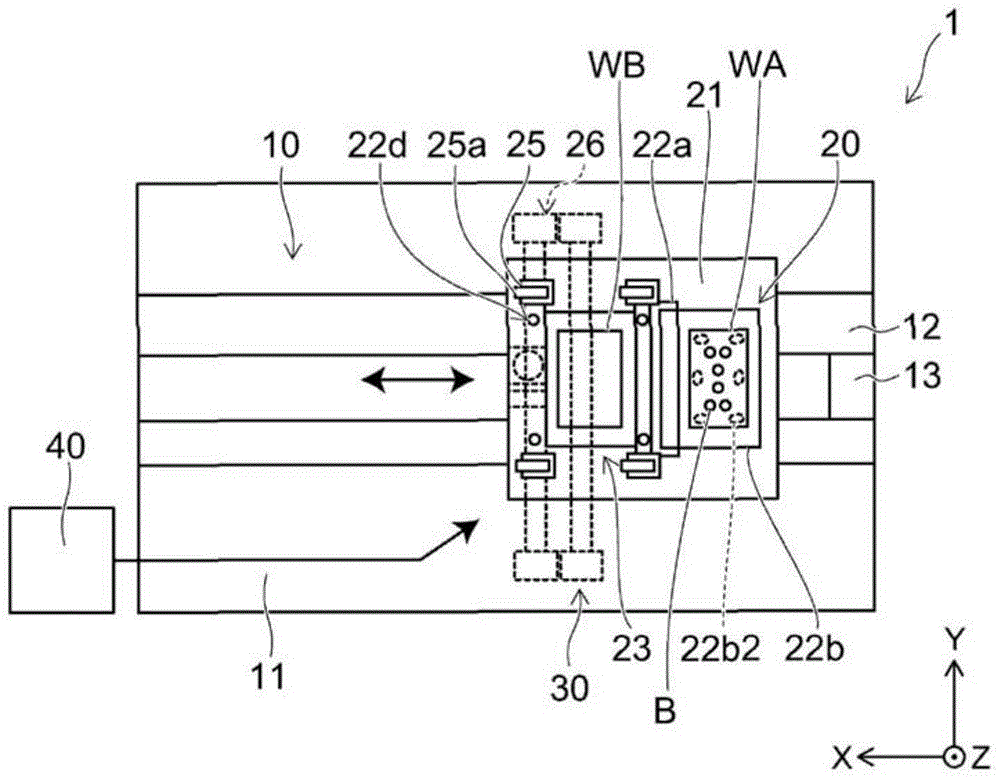

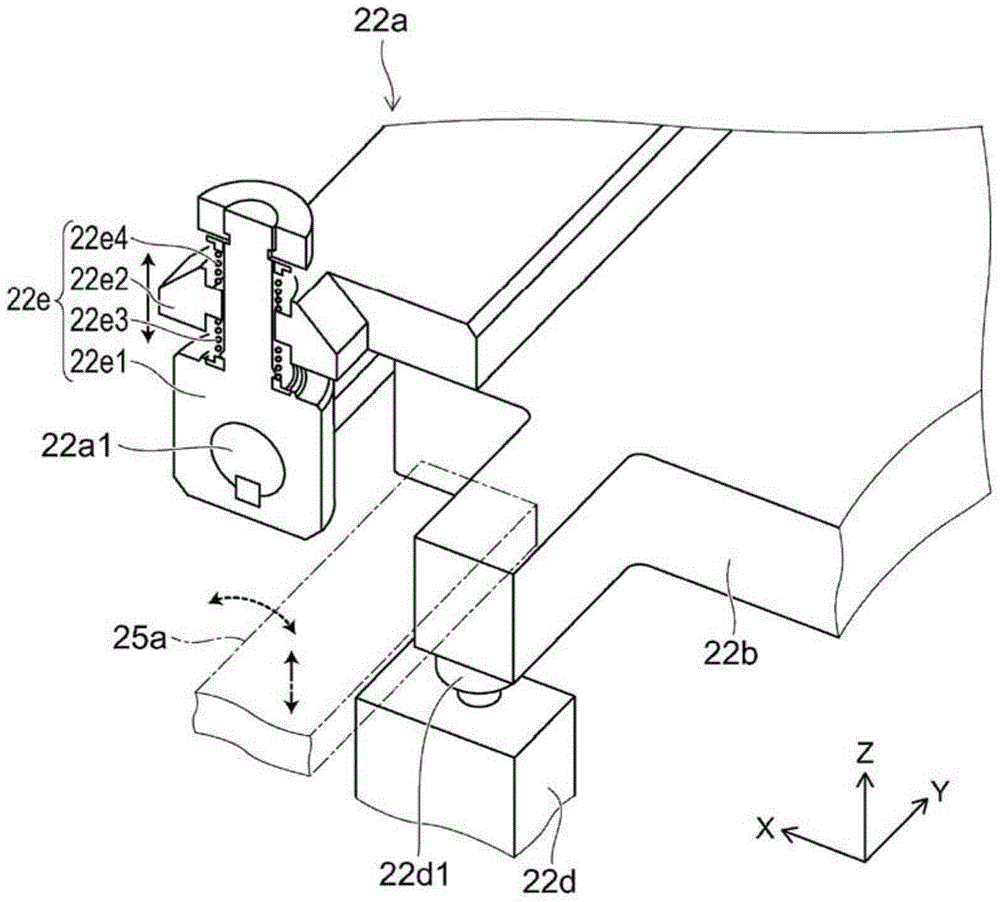

[0015] Embodiments are illustrated below with reference to the drawings. In addition, in each drawing, the same code|symbol is attached|subjected to the same component, and detailed description is abbreviate|omitted suitably.

[0016] In addition, arrows X, Y, and Z in each drawing indicate three directions perpendicular to each other, for example, arrows X, Y indicate a horizontal direction, and arrow Z indicates a vertical direction.

[0017] In addition, the display device in the display device manufacturing apparatus 1 and the display device manufacturing method of the present embodiment can be a device having a pair of substrates facing each other. For example, the display device is a liquid crystal display device, an organic EL (Organic Electro Luminescence) display device, or the like. In addition, the substrate WA (corresponding to an example of the first substrate) and the substrate WB (corresponding to an example of the second substrate) described later are, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com