Process for mfg. unidimensional X ray refracted diffraction micro structural component of aluminium material

A manufacturing method and X-ray technology, applied in the field of X-ray microstructured optical devices, can solve the problems of small material restrictions, large material restrictions, and high roughness, so as to reduce X-ray absorption, increase light collection aperture, and improve transmission rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

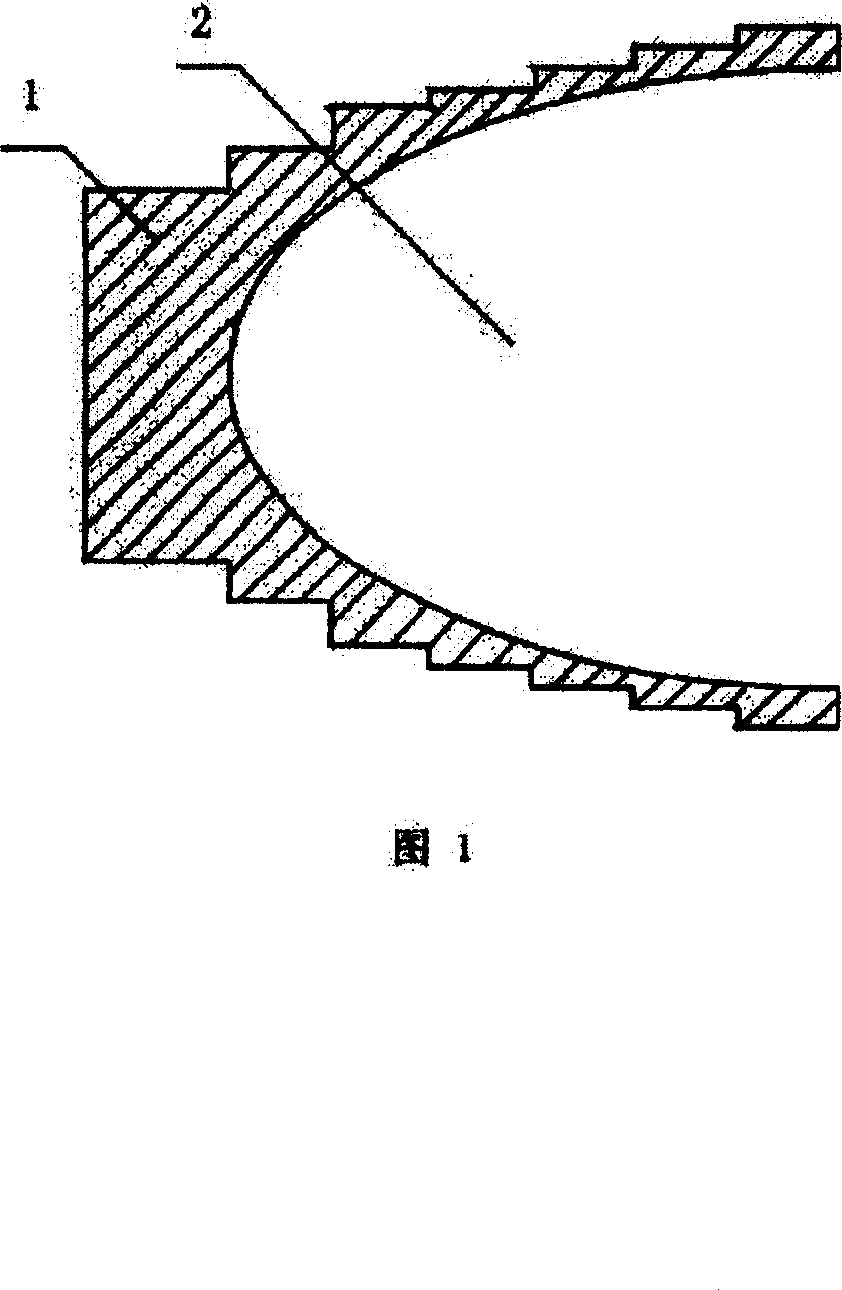

[0032] Referring to accompanying drawing 1, a kind of manufacturing method of one-dimensional X-ray diffraction microstructure device of aluminum material, described one-dimensional X-ray diffraction microstructure device is made up of a plurality of lens units of coaxial order successively, and described lens unit It consists of a lens body with an air gap, the upper side wall of the lens body has upward stepped steps, and the step width of each step is equal; the lower side wall of the lens body has a shaft as the center line Downward stepped steps arranged symmetrically with the steps on the upper side wall of the lens, the lens body is provided with the open air gap, the cross-sectional shape of the air gap is elliptical, and the air gap corresponds to the minor axis of the ellipse The largest aperture dimension in the direction is smaller than the minor axis dimension of the ellipse, and the major axis of the elliptical air gap of the lens unit is located on the same strai...

Embodiment 2

[0051] In the technical scheme of the present embodiment, the metal material electroforming cathode film described in the step (B) is a titanium material, and the thickness of the PMMA coating on the surface of the titanium sheet is 500 microns in the step (1), and all the other steps are the same as in Example 1.

Embodiment 3

[0053] In the technical scheme of the present embodiment, the metal material electroforming cathode film described in the step (B) is a nickel material, and the thickness of the PMMA coating on the surface of the titanium sheet is 2000 microns in the step (1), and all the other steps are the same as in Example 1.

[0054] Process tests have been carried out on the above three embodiments, and it can be seen from the test results that they all meet the requirements of the structural shape and size of the X-ray combined lens, and the process test effect of embodiment 2 is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com