Process for mfg. one-dimensional X ray refracted diffraction micro structural component of polymethyl methyl acrylate material

A technology of polymethyl methacrylate and production method, applied in X-ray/γ-ray/particle irradiation therapy, analyzing materials, material analysis using wave/particle radiation, etc., can solve the problem of low depth of device structure and surface roughness It can achieve the effect of small material limitation, good focal spot quality, and reduced X-ray absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

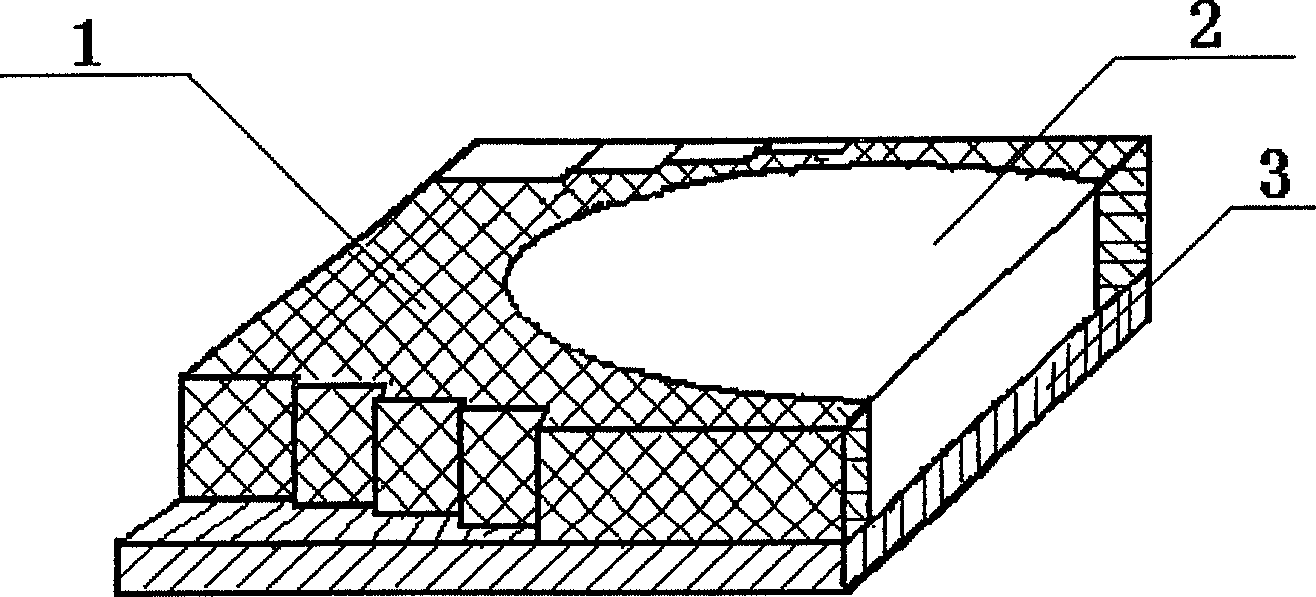

[0029] Referring to accompanying drawing 1, a kind of manufacturing method of polymethyl methacrylate material one-dimensional X-ray diffraction microstructure device, described one-dimensional X-ray diffraction microstructure device comprises a plurality of lens units arranged coaxially in sequence , the lens unit is composed of a lens composed of a main body with an air gap, the upper side wall of the lens main body has upward stepped steps, and the step width of each step is equal; the lower side of the lens main body The wall is provided with a downward step-like step symmetrically arranged with the axis as the center line and the step of the upper side wall of the lens. The lens is provided with an open air gap. The maximum diameter of the gap corresponding to the direction of the minor axis of the ellipse is smaller than the minor axis of the ellipse, and the major axes of the elliptical air gaps of the lens unit are located on the same straight line. The manufacturing me...

Embodiment 2

[0044] In the technical scheme of the present embodiment, the thickness of the polyimide material is 5 microns in the step (C), and the metal material electroforming cathode film described in the step (D) is a titanium material, and the surface of the titanium sheet is coated with The thickness of coating polymethyl methacrylate is 500 microns, and all the other steps are identical with embodiment 1.

Embodiment 3

[0046] In the technical scheme of the present embodiment, the metal material electroforming cathode film described in the step (D) is a titanium material, and the thickness is 400 nanometers, and the thickness of the polymethyl methacrylate coated on the surface of the titanium sheet is 800 nm in the step (K). Micron, all the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com