Aligning jump hammer tamping tool

A technology of tamping machine and splint hammer, which is applied in the mechanical treatment of coal loaded into the furnace, the petroleum industry, coking ovens, etc., and can solve the problems of difficult adjustment of manufacturing assembly, deviation wear, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

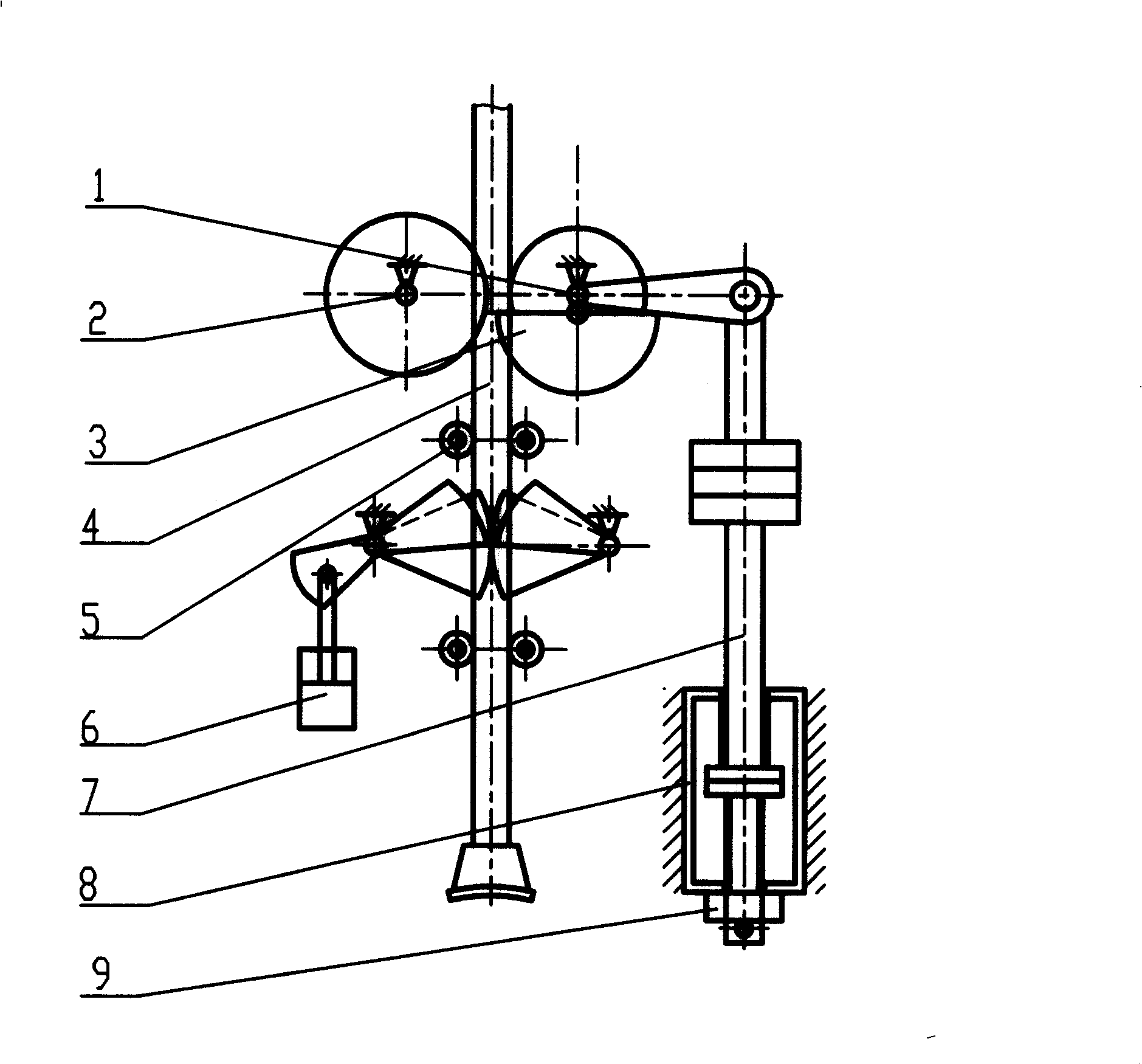

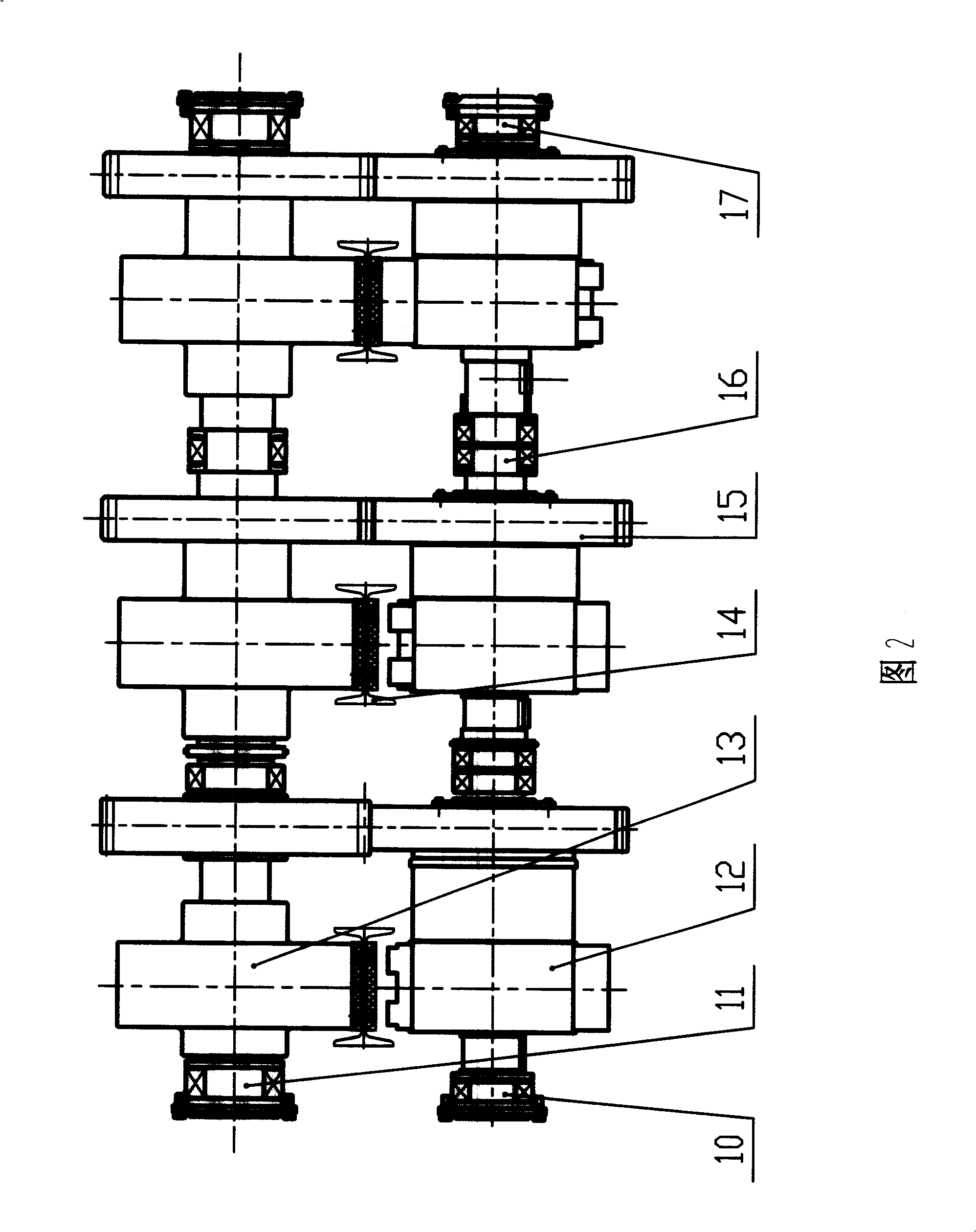

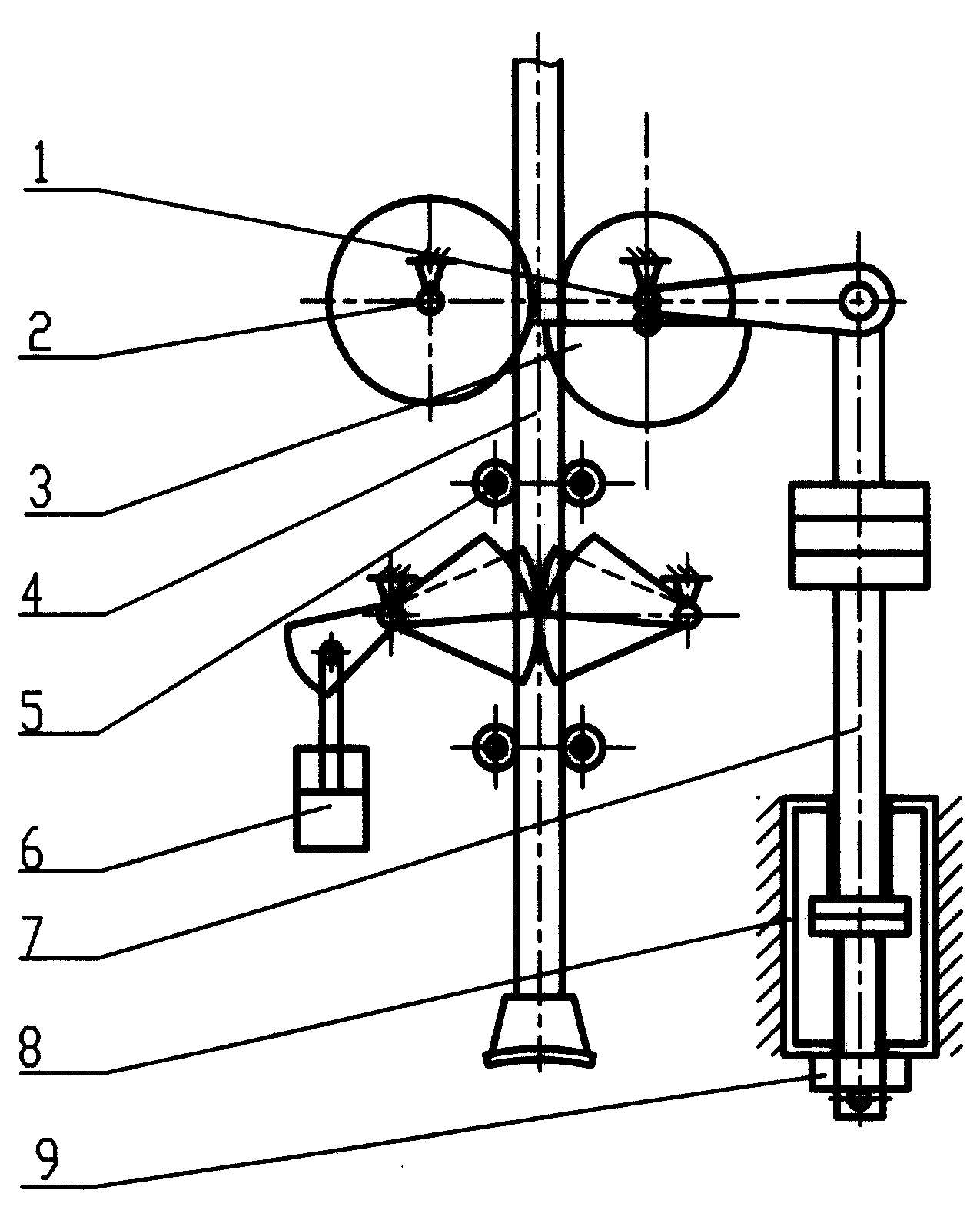

[0008] Specific embodiment: this self-aligning type splint hammer tamping machine as shown in the accompanying drawing has car body, the frame that is arranged on car body, the driving transmission mechanism that is arranged on frame and lifts the hammer mechanism, also is arranged on Tamping hammer 4 between frame guide wheel group 5. The car body also has a walking mechanism. The lower end of the frame is provided with an electric control mechanism and an operating mechanism. It is characterized in that the clamping parts of the hammer lifting mechanism are a friction wheel 2 and a half-ring friction cam 3 respectively arranged on both sides of the tamping hammer rod. The synchronously meshed gear 15 of the friction wheel and the half-ring friction cam meshes with the transmission gear of the drive transmission (see FIG. 2 ). The hammer lifting mechanism, the guide wheel group and the tamping hammer that are arranged on the frame are three groups (see Fig. 2) juxtaposed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com