Pushing type garbage cleaning vehicle

A sweeping vehicle and push-and-go technology, which is applied to road cleaning, cleaning methods, construction, etc., can solve the problems of affecting the garbage winding capacity and the small volume of the garbage storage chamber, and achieve the effect of sustainable long working stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

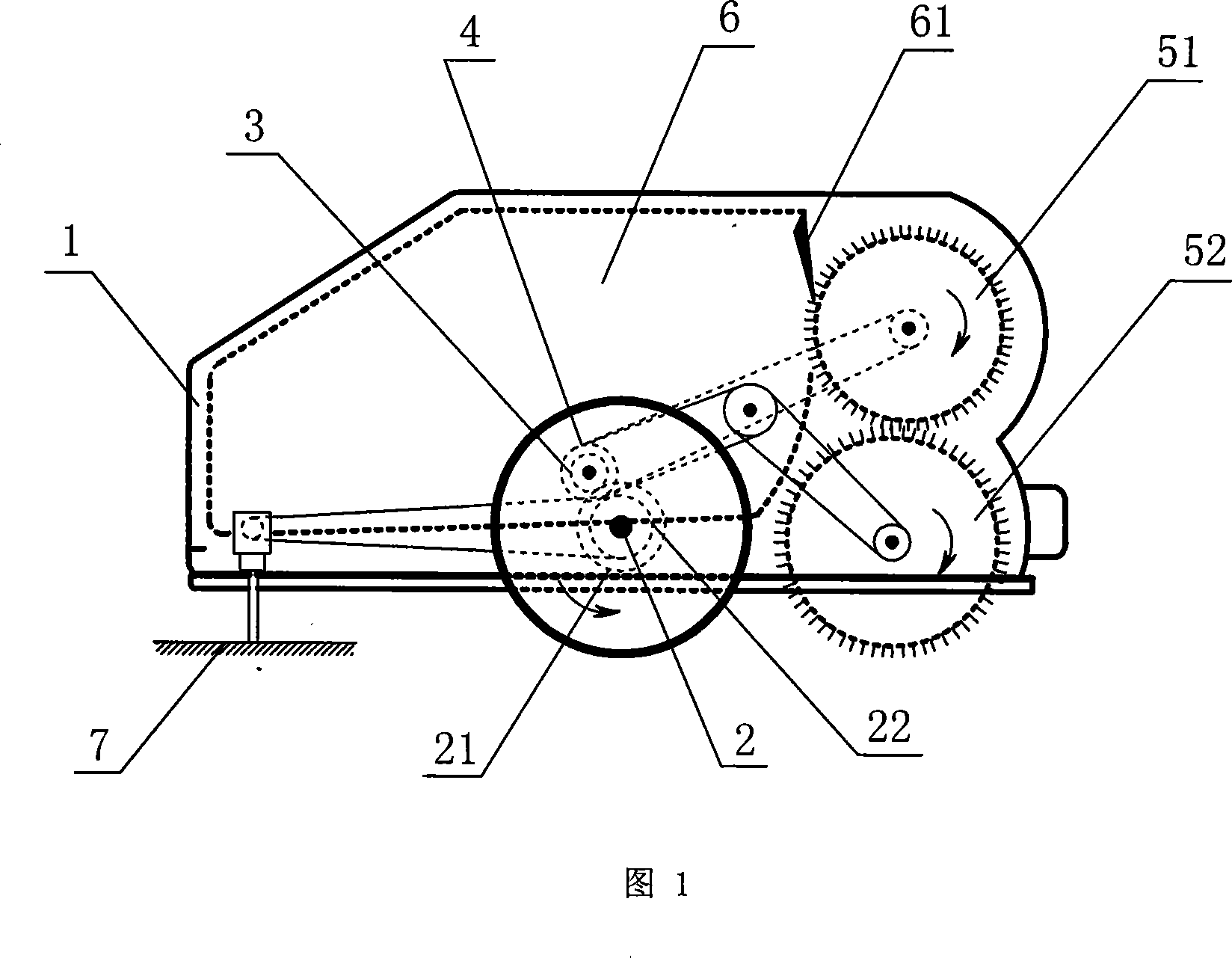

[0013] As shown in Figure 1, a push-type garbage sweeper has a vehicle body 1 with wheels on both sides of the vehicle body 1, and the wheels have a rotating shaft 2, and a driving gear 21 is arranged on the wheel rotating shaft 2, and a drive gear 21 is correspondingly arranged beside the driving gear 21. Coaxial reversing gear 3 and transmission sprocket 4, reversing gear 3 meshes with driving gear 21; upper and lower roller brushes 51 and lower roller brushes 52 with bristles in cross contact are arranged side by side in the body 1, and the lower roller brush 52 touches the ground The ends of the respective rotating shafts of the two roller brushes are provided with sprockets, and are all chained by the drive sprocket 4; the front positions of the two roller brushes in the vehicle body 1 are provided with a garbage storage cavity 6, and the entrance of the garbage storage cavity 6 is set At the front position of the upper roller brush 51 and close to the upper roller brush 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com