Shearing type lead damper

A technology of shear type and damper, which is applied in the direction of building components, earthquake resistance, etc., to achieve the effect of simplified connection, high practical application value, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiments.

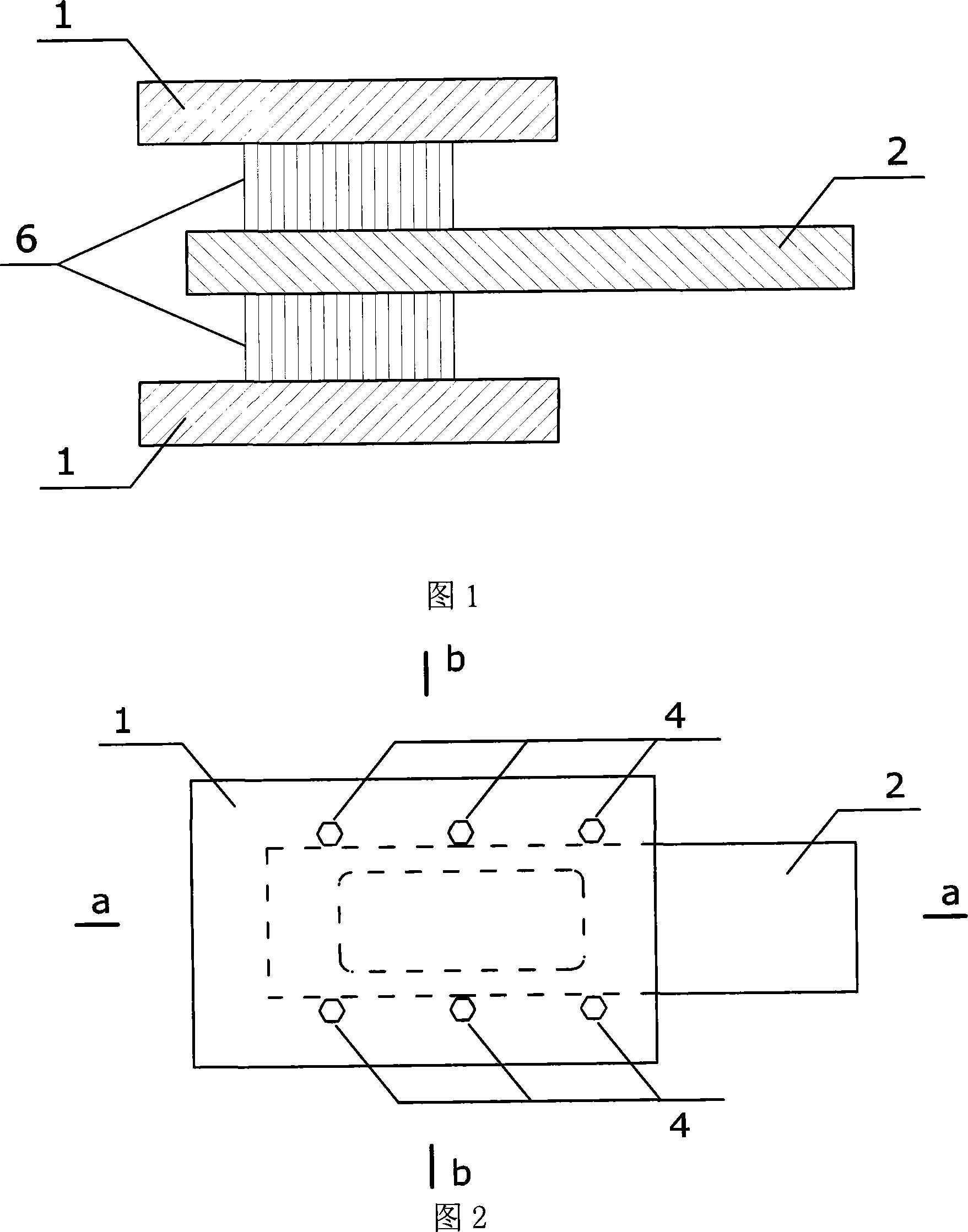

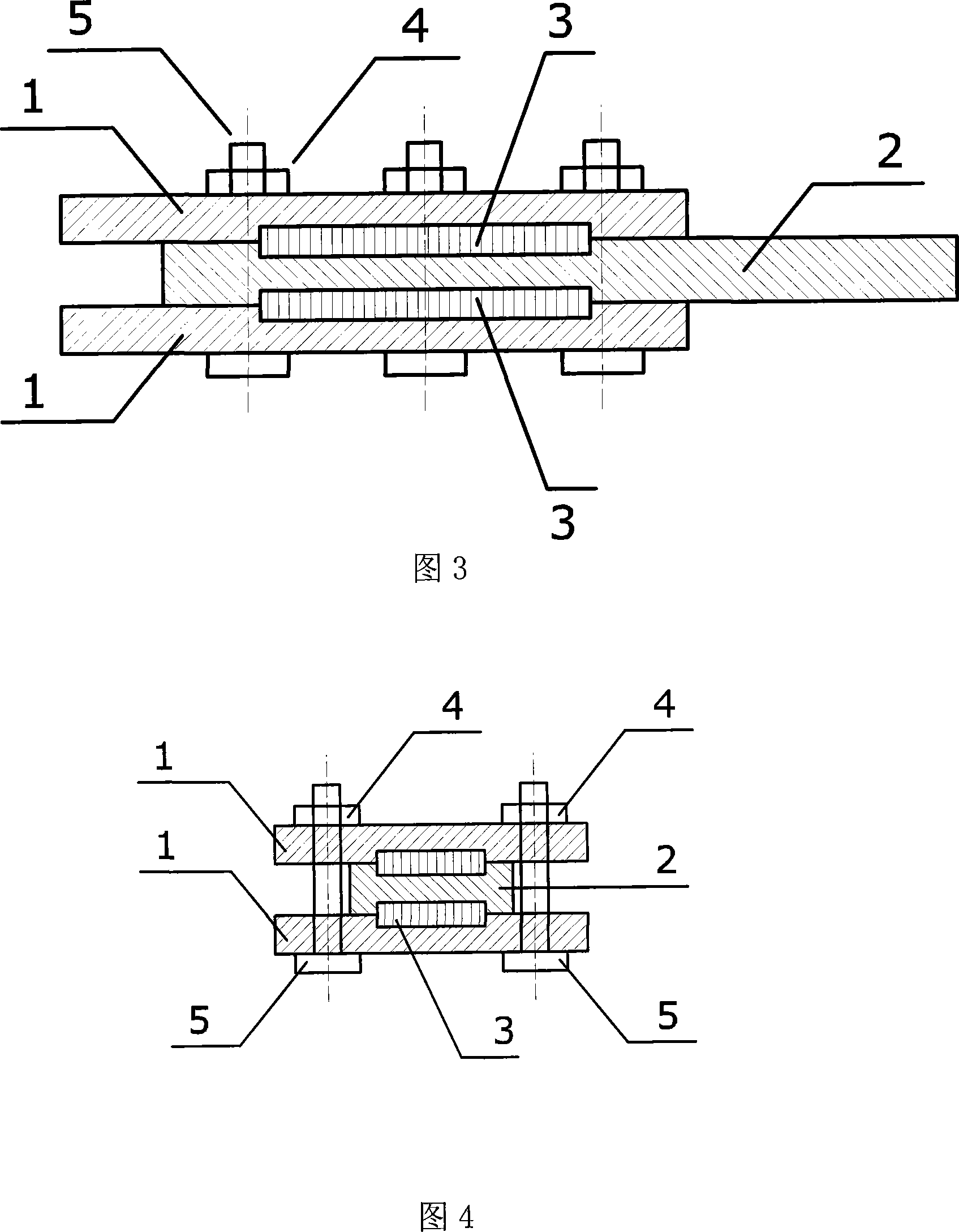

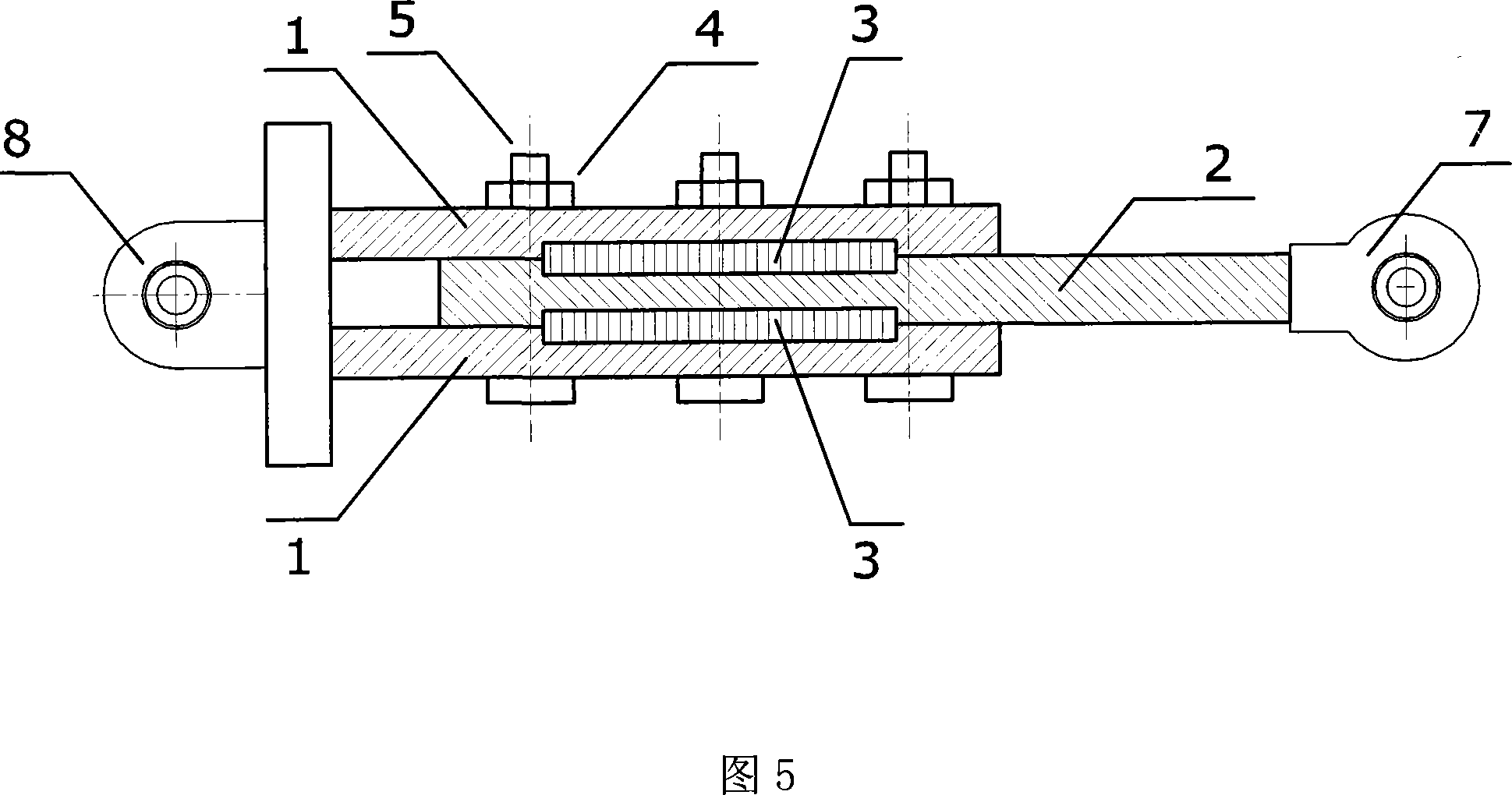

[0014] As shown in Figure 5, the shear-type lead damper includes two upper and lower cover plates 1 and a sliding plate 2. The two cover plates 1 are respectively buckled on the upper and lower surfaces of the sliding plate 2. The two cover plates 1 and Each contact surface of the sliding plate 2 is provided with a groove, and the four grooves are positioned oppositely and have the same size, forming two upper and lower cavities, and the shearing lead block 3 is directly embedded in the two cavities. A number of screw rods 5 are passed through the two cover plates 1, and the screw rods 5 are locked by a lock nut 4 to fix the two cover plates 1 and the sliding plate 2 and the shearing lead block 3 sandwiched between the two cover plates 1. The two cover plates 1 and the hinged end plate 8 are welded together, and the sliding plate 2 is welded to the connecting hinge 7.

[0015] The shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com