Light source for high efficiency illumination systems

A light beam and filament technology, applied in the field of lighting systems, can solve problems such as light waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

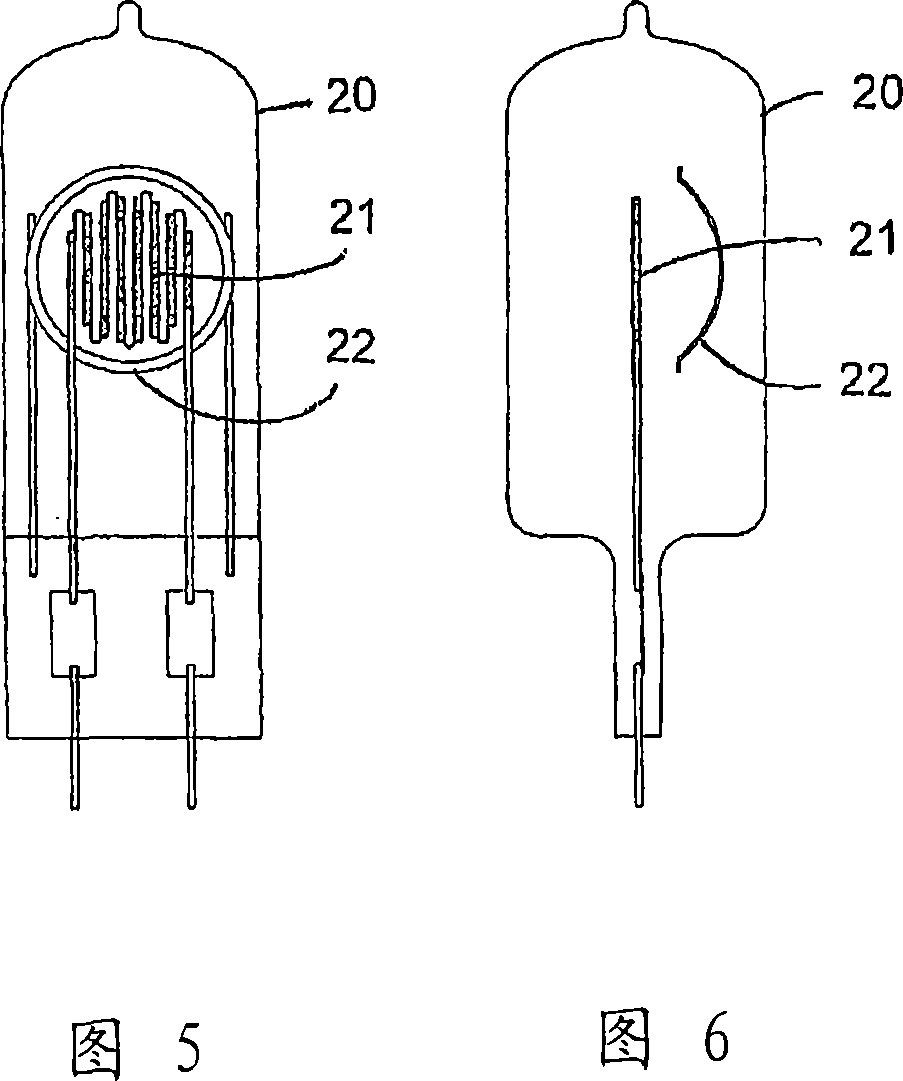

[0024] An exemplary embodiment of the present invention in which the light source is an incandescent filament will be described below with reference to FIG. 4 . Fig. 4 shows a view of the monoplanar incandescent filament array of the present invention as viewed from a position perpendicular to the spherical reflector. Referring to Fig. 4, it can be seen that the filament array comprises eight parallel helically wound coil sections. The outer filament section 7 is considerably shorter than the inner filament section 8, while the intermediate section 9, 10 between the outer and inner sections has an intermediate length. And the circle 11 shown in this figure represents the aperture through which the light emitted from this filament array will have to pass. It can be seen that each portion has a length that exceeds the boundaries of the circle. The fraction of the filament that emits light that would not pass through the aperture and would therefore be wasted, corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com