Papermaking felt

A wool and felt technology, used in papermaking, papermaking, textiles and papermaking, etc., to achieve the effect of extending service life and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

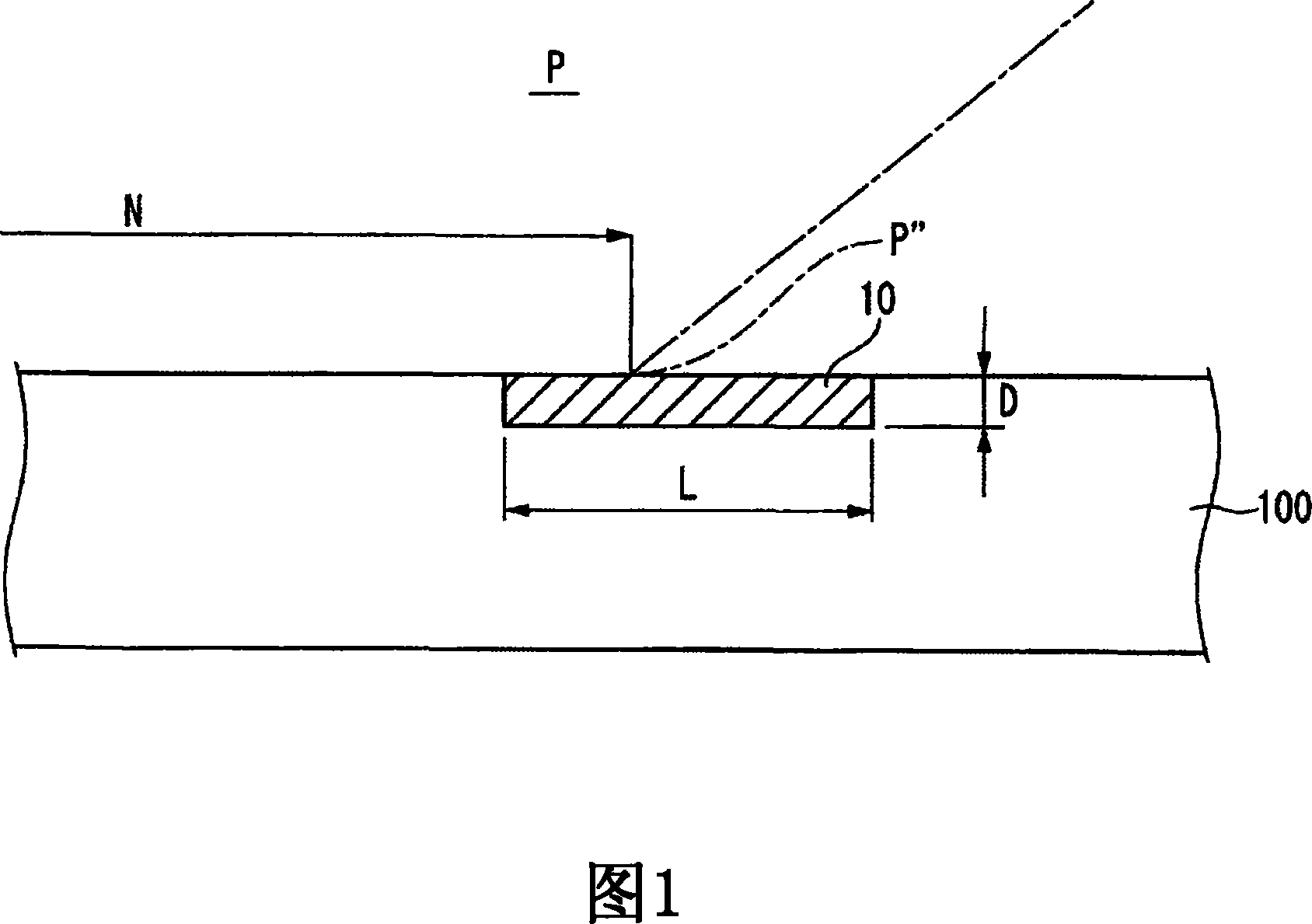

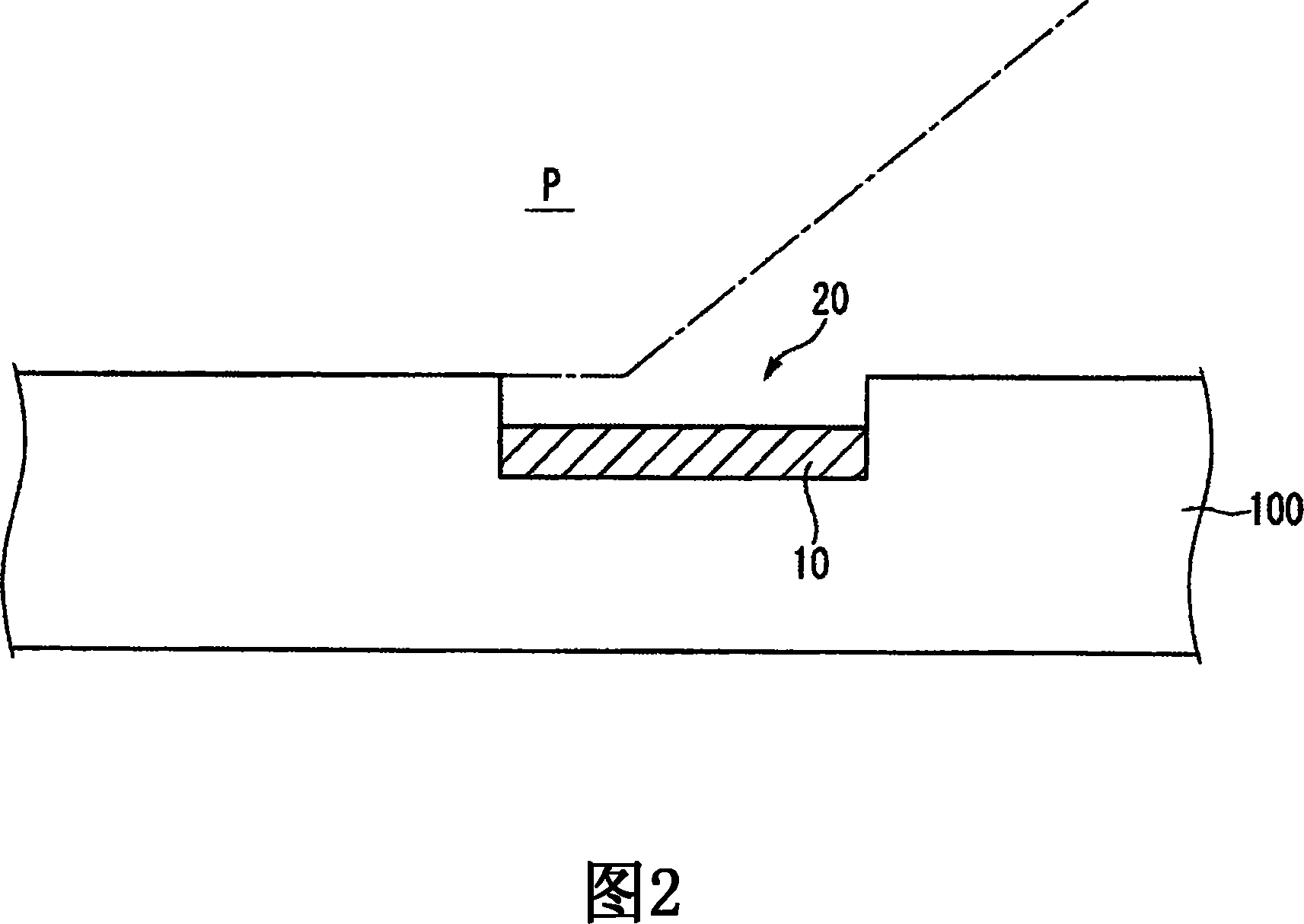

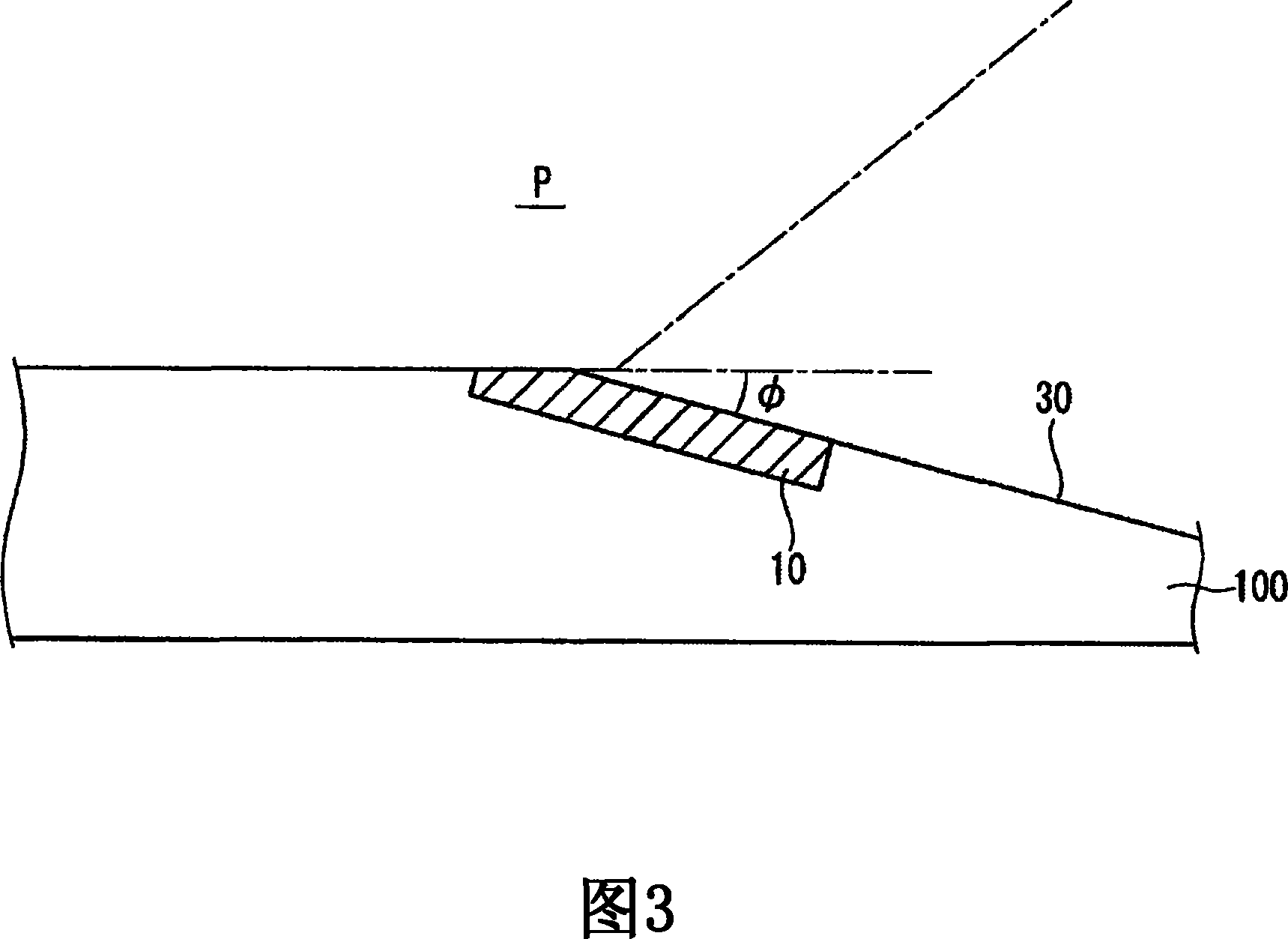

[0022] Hereinafter, a detailed description of the present invention will be described.

[0023] In the present invention, there is no particular limitation except that the protective layer is formed on the contact portion of the papermaking felt which is in contact with the edge of the squeeze roll. Therefore, the papermaking felt on which the protective layer is formed is not limited. However, the following are some examples of papermaking felts.

[0024] In general, papermaking felts have a base member that is sandwiched between layers of felt. Typically, textiles woven from warp and weft threads are used as base components, for example, in looms. The raw materials for warp and weft can be polyester (such as polyethylene terephthalate or polybutylene terephthalate), polyamide (such as polyamide-6, polyamide-66, polyamide -610 or polyamide-612), polyphenylene sulfide, polyvinylidene fluoride, polypropylene, aramide, polyether ether ketone, polytetrafluoroethylene, polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com