Independent measuring apparatus for grinding machines

A technology of measuring devices and grinding machines, applied in the direction of mechanical measuring devices, measuring devices, adopting mechanical devices, etc., can solve the problems of increasing cycle time, structural change errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

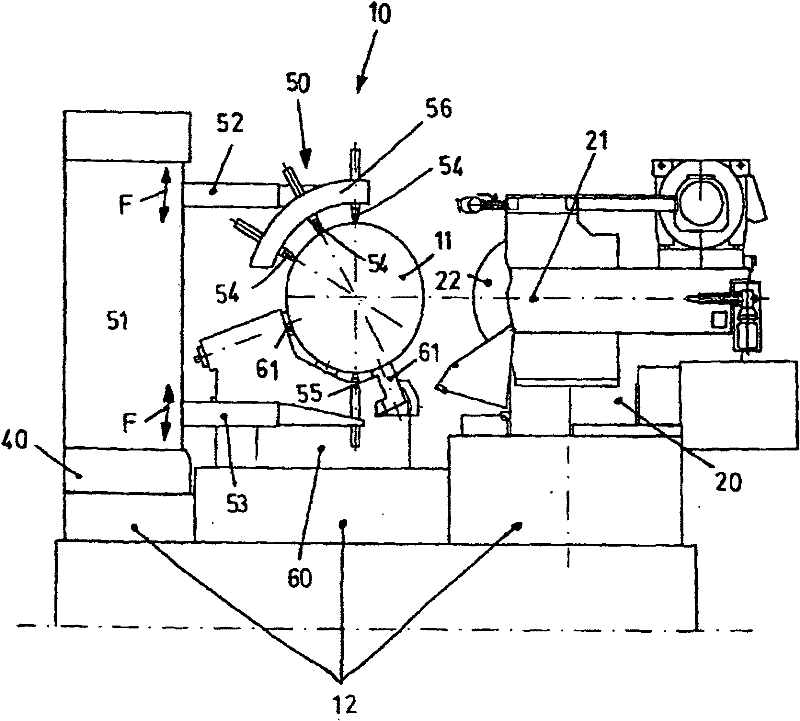

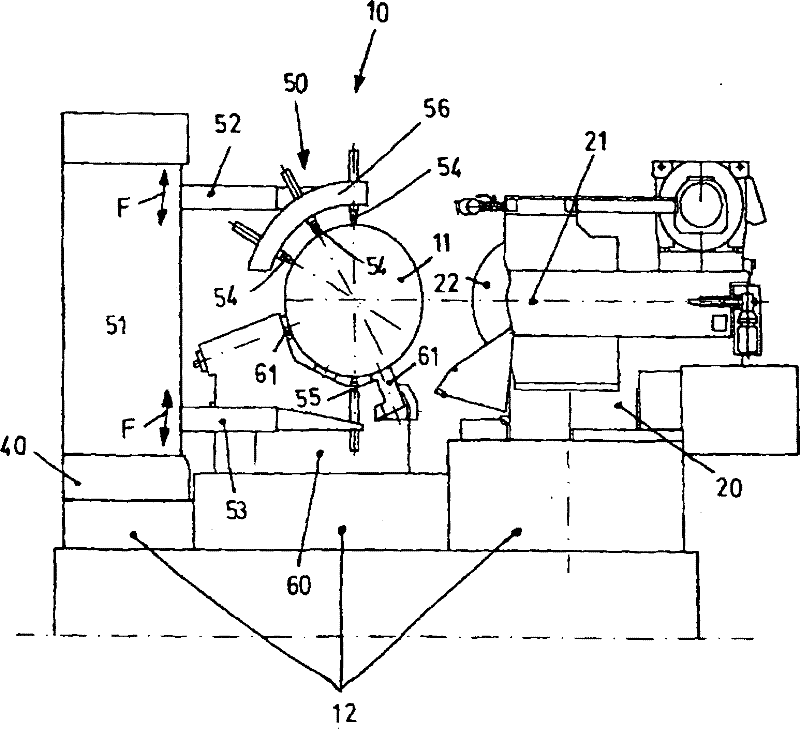

[0023] With reference to the drawings, a grinding machine 10 for cylinders 11, rollers and similar elements comprises at least one base 12, a grinding trolley 20 carrying a grinding unit 21 equipped with grinding wheels 22 and the support of individual gauges A rocking carriage (load measuring device 50 ) is movably supported along this base 12 .

[0024] The measuring and detecting device 50 for the geometry of the cylinders 11 is not only used for cylinders coming from rolling mills (in order to obtain strips made of metallic material), but can also be used in other sectors, including cylinders, rolls and other for paper mills Grinding treatment of similar components, usually flat non-ferrous or steel rolled parts and / or areas, such as marine engine structures and / or large-scale hydraulic systems.

[0025] Thus, the measuring and detection device 50 is assembled on an independent system, the measuring trolley 40 (as a first specific feature) is made with a clamp-like structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com