Water permeating pipeline, film or container for agricultural irrigation, manufacturing method and uses thereof

A technology for agricultural irrigation and water seepage pipelines, applied in the application, agriculture, and botany equipment and methods, etc., can solve the problems of high cost, clogging, inconvenient use, etc., and achieve the effects of low cost, uniform irrigation, and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

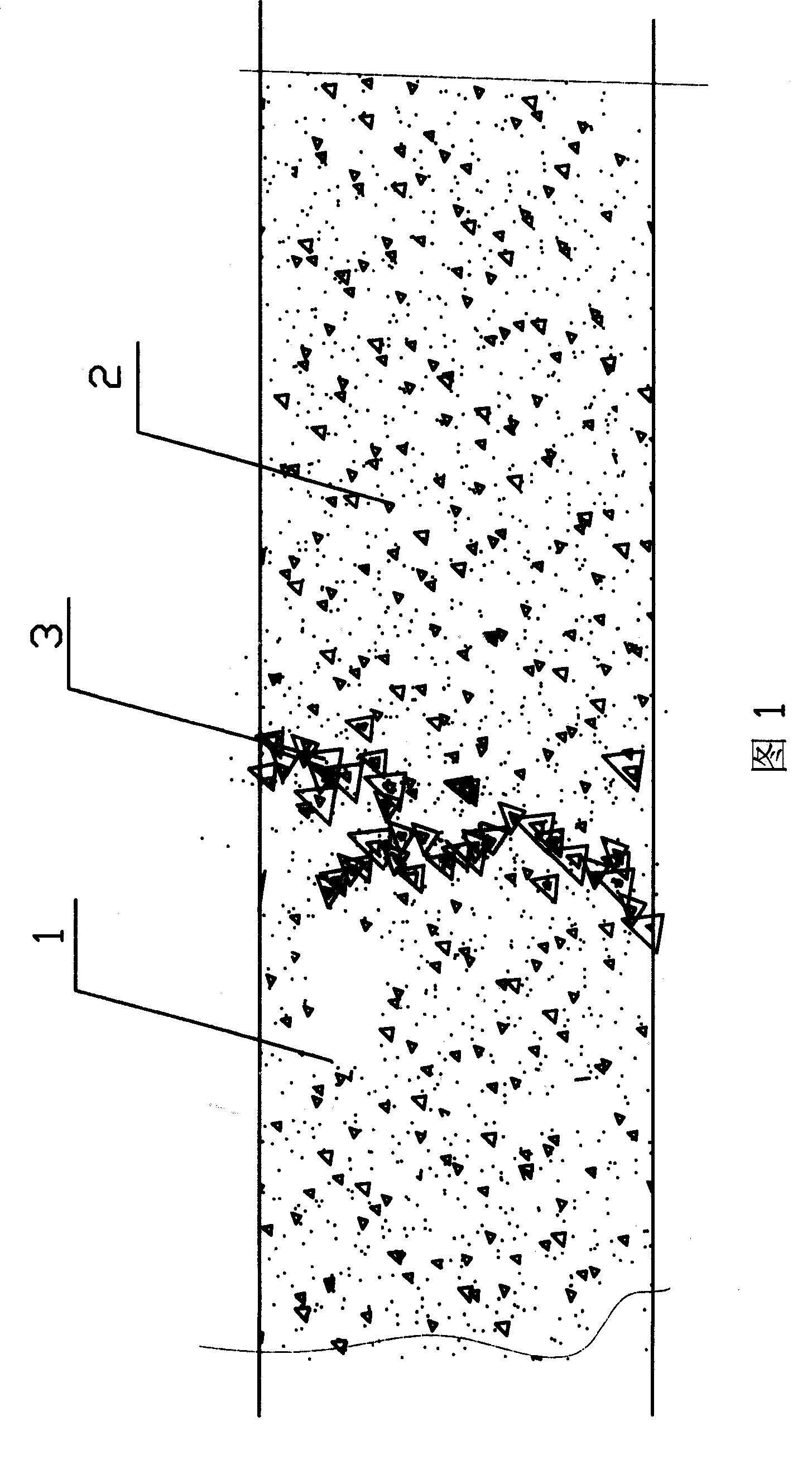

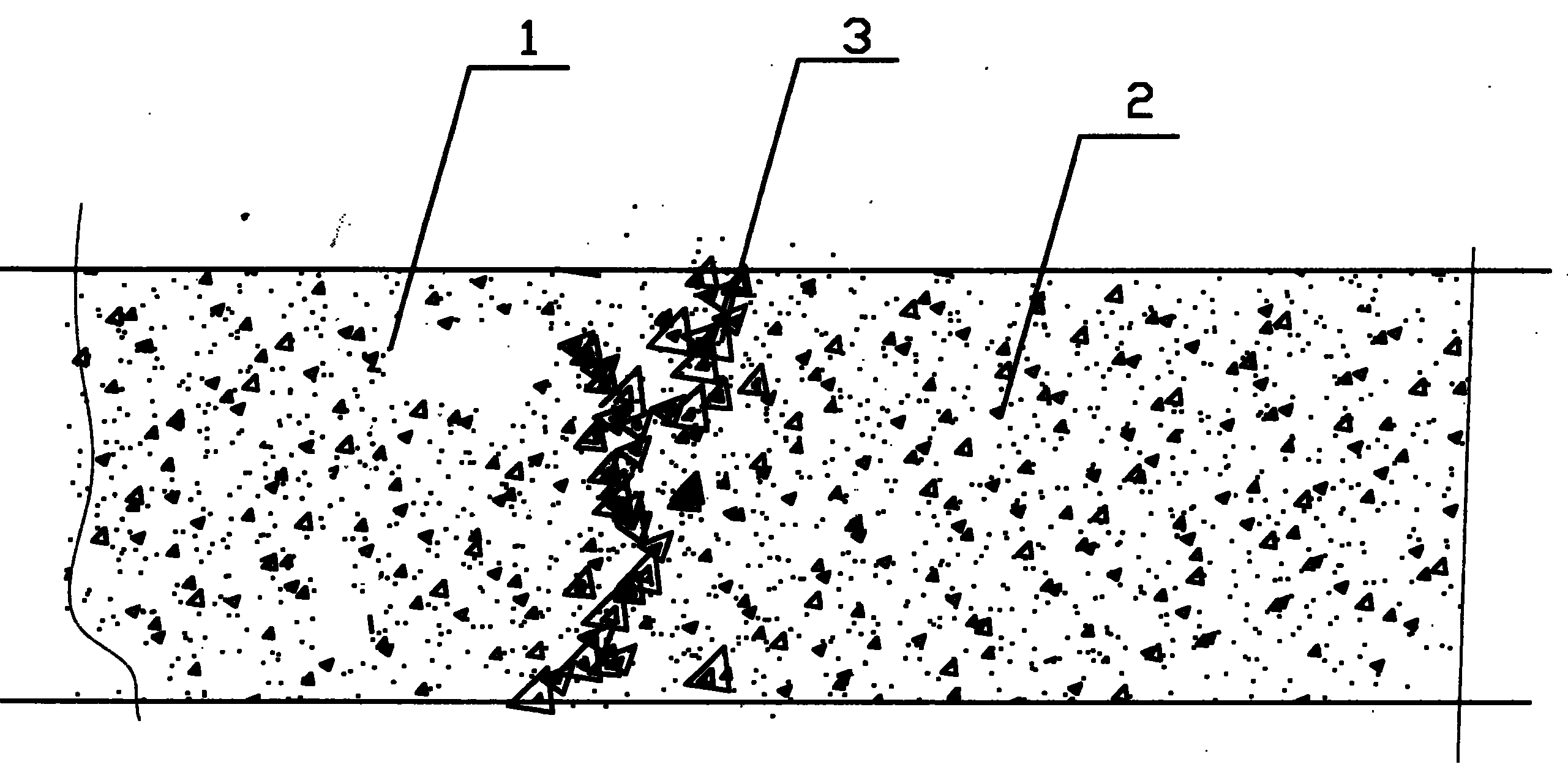

[0025] The seepage pipe or film or container for agricultural irrigation comprises: a plasticized molding material matrix 1, an inert filler 2 with a melting point higher than the plasticizing temperature is added to the plasticized molding material matrix, and the inert filler means that it cannot It melts at the processing temperature of the plastic and cannot be fused with the melted plastic to form a homogeneous material. The inert filler is coated in a release agent. The release agent refers to a certain compatibility with the matrix and can The material that forms a layer of liquid film on the surface of the above-mentioned inert filler, this release agent exists in the middle of the two phases of the inert filler phase and the plastic during the subsequent processing, to isolate the two phases and prevent the inert filler particles from directly contacting the plastic material In contact, the spacer dissolves into the matrix material to form a curved leakage channel 3 by...

Embodiment 2

[0027] Water seepage pipes or membranes or containers for agricultural irrigation, the composition of which includes: polyethylene as a matrix, inert fillers with a melting point higher than the plasticizing temperature of polyethylene, such as powdery bentonite, white carbon black, A mixture of one or more substances in activated carbon, calcium carbonate or starch in arbitrary proportions, the inert filler is coated in a release agent, and the release agent has a certain compatibility with the matrix and can be used in the above-mentioned The material that forms a layer of liquid film on the surface of the inert filler, this release agent exists in the middle of the inert filler phase and the plastic phase during subsequent processing, to isolate the two phases and prevent the inert filler particles from directly contacting the plastic material , including a mixture of one or more substances in liquid paraffin, silicone oil or lubricating oil in any proportion. A curved leak...

Embodiment 3

[0029] Seepage pipes or membranes or containers for agricultural irrigation, the composition of which includes: polyvinyl chloride as a matrix of plasticized molding materials, inert fillers with a melting point higher than the plasticizing temperature of polyvinyl chloride, such as powdered A mixture of one or more substances in bentonite, white carbon black, activated carbon, calcium carbonate or starch in any proportion. The inert filler means that it cannot be melted at the processing temperature of the plastic, nor can it be fused with the melted plastic to form a A homogeneous material, the inert filler is coated in a release agent, the release agent refers to a material that has a certain compatibility with the matrix and can form a layer of liquid film on the surface of the above inert filler, this release agent It exists in the middle of the inert filler phase and the plastic phase in the subsequent processing to isolate the two phases and prevent the inert filler part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com