Nail gun

A technology of nail guns and nail magazines, applied in the field of nail guns, which can solve problems such as unfavorable nail gun troubleshooting operations, delayed completion of nail gun work, and stuck nails, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Several preferred embodiments of the present invention are listed below, and will be described in detail in conjunction with the accompanying drawings.

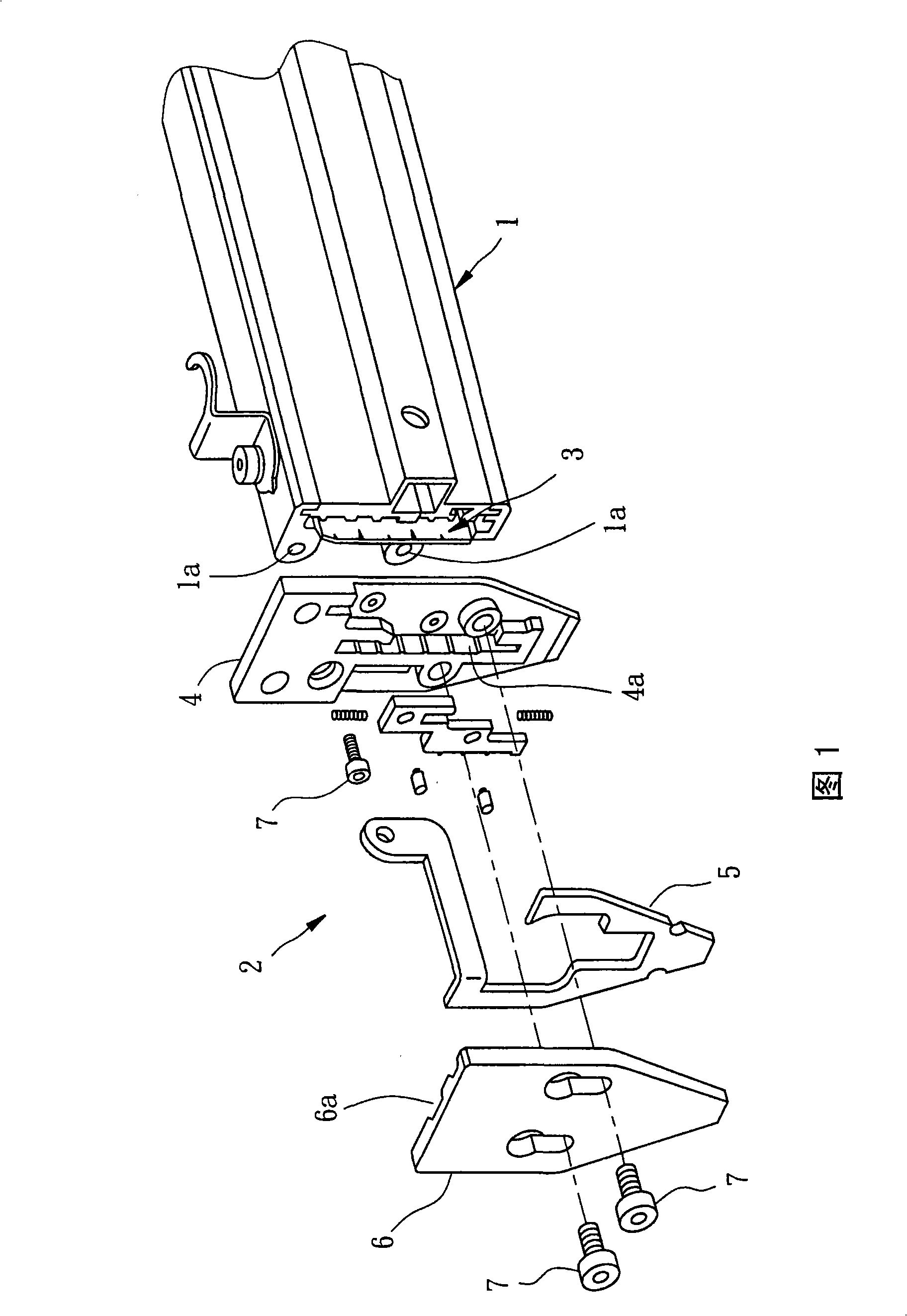

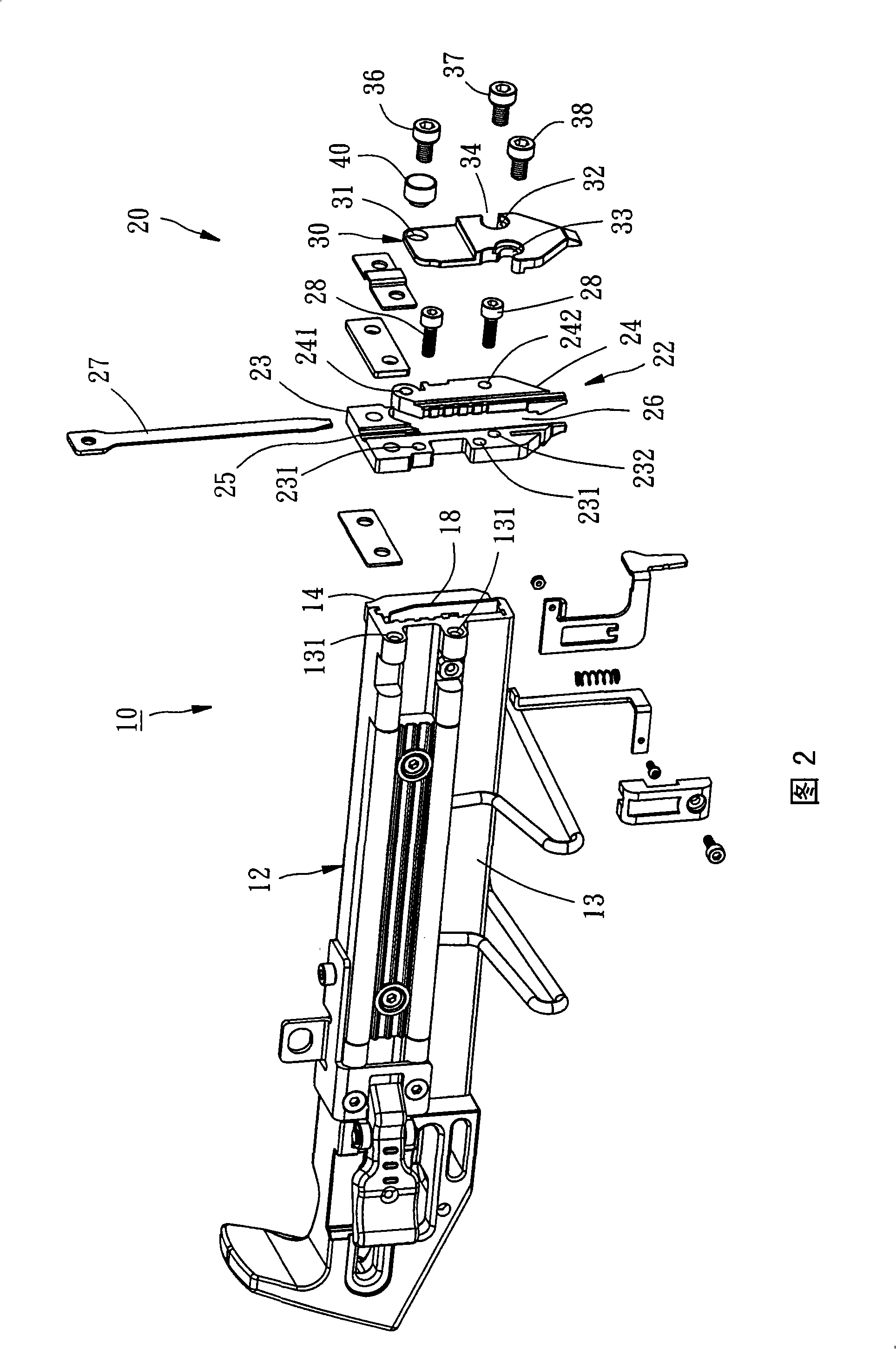

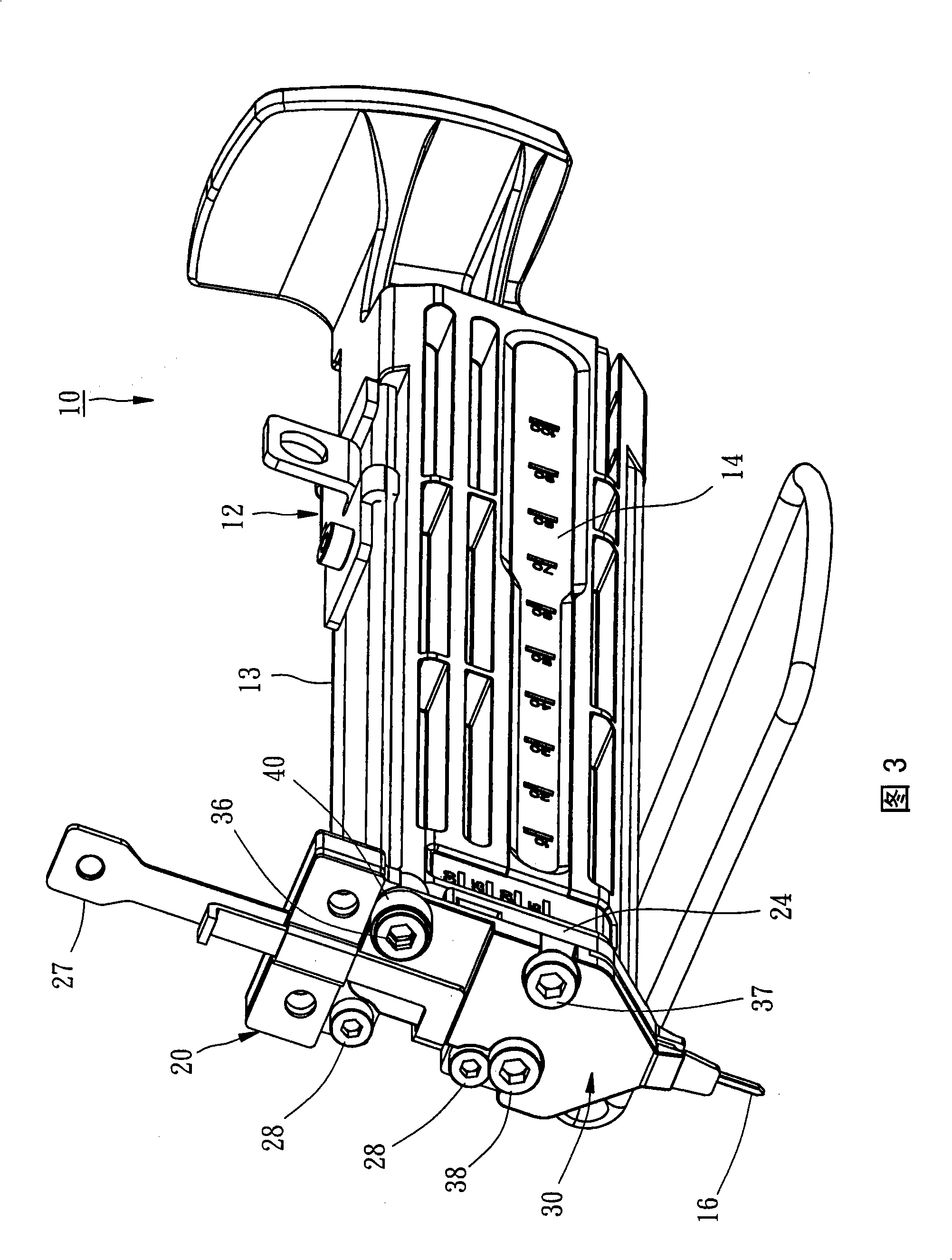

[0045] 2 to 4 illustrate two parts of the nail magazine 12 and the nozzle 20 of the nail gun 10 according to a preferred embodiment of the present invention.

[0046] Wherein the nail box 12 includes a left side cover 13 and a right side cover 14, the front side of the left side cover 13 has two screw holes 131, and the right side cover 14 is slidable with the left side cover 13. The left side cover 13 is combined, and the interior of the nail box 12 is provided with a plurality of nail bodies 16 and a nail pushing member 18 for pushing the nail bodies 16 toward the front end of the nail box 12 .

[0047] The gun nozzle 20 includes a needle slot seat 22, a striker 27, two fixing bolts 28, a front cover 30, a first to a third bolt 36-38 and a bolt sleeve 40, wherein:

[0048] The needle groove seat 22 includes a left n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap