Multi-saw blade band sawing machine and saw wheel rotating method

A band saw machine and saw wheel technology, applied in band saws, sawing equipment, wood processing equipment, etc., can solve the problems of single working mode, large energy consumption, inconvenient adjustment and operation, etc., and achieve the effect of improving work efficiency and saving energy Good, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

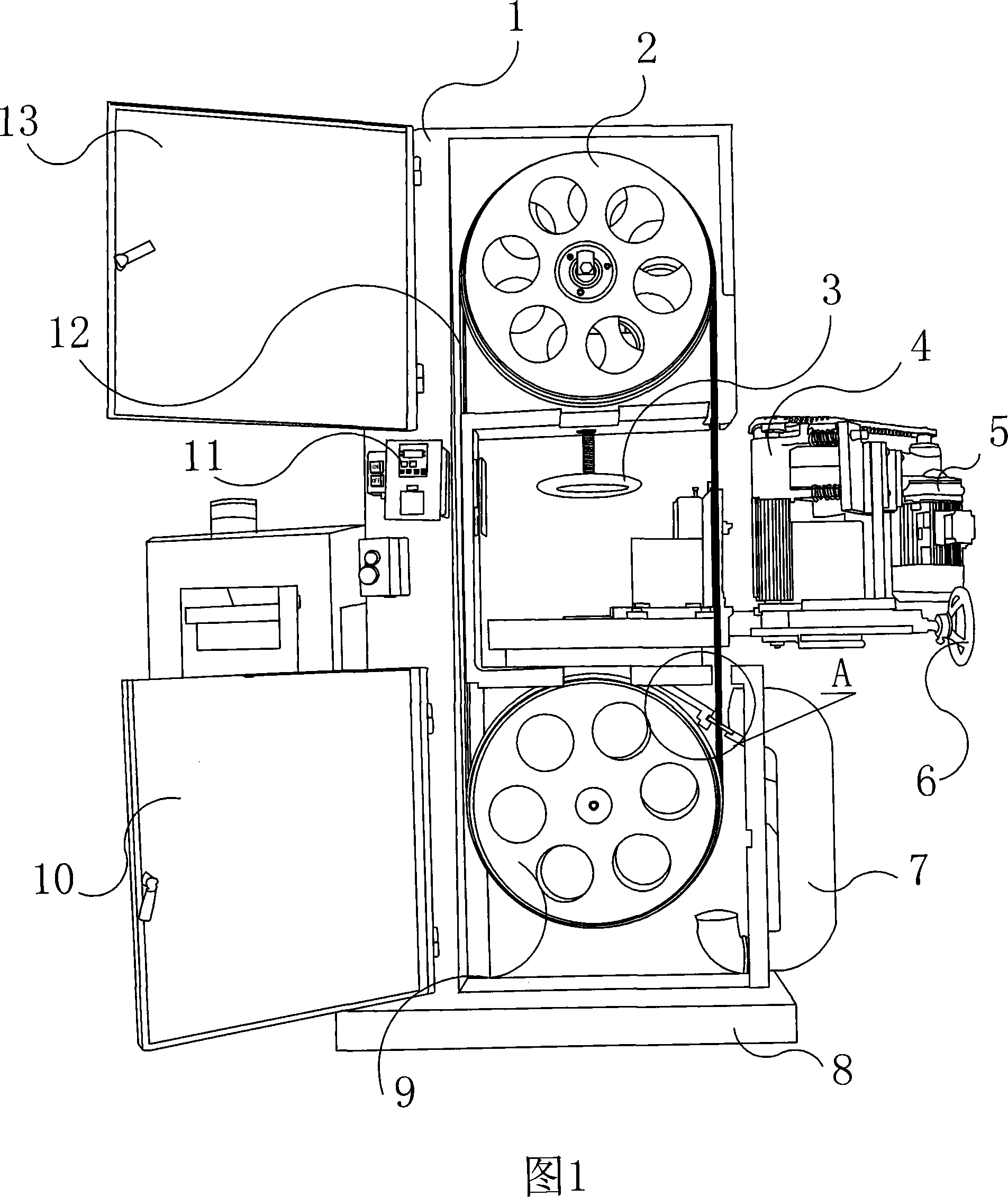

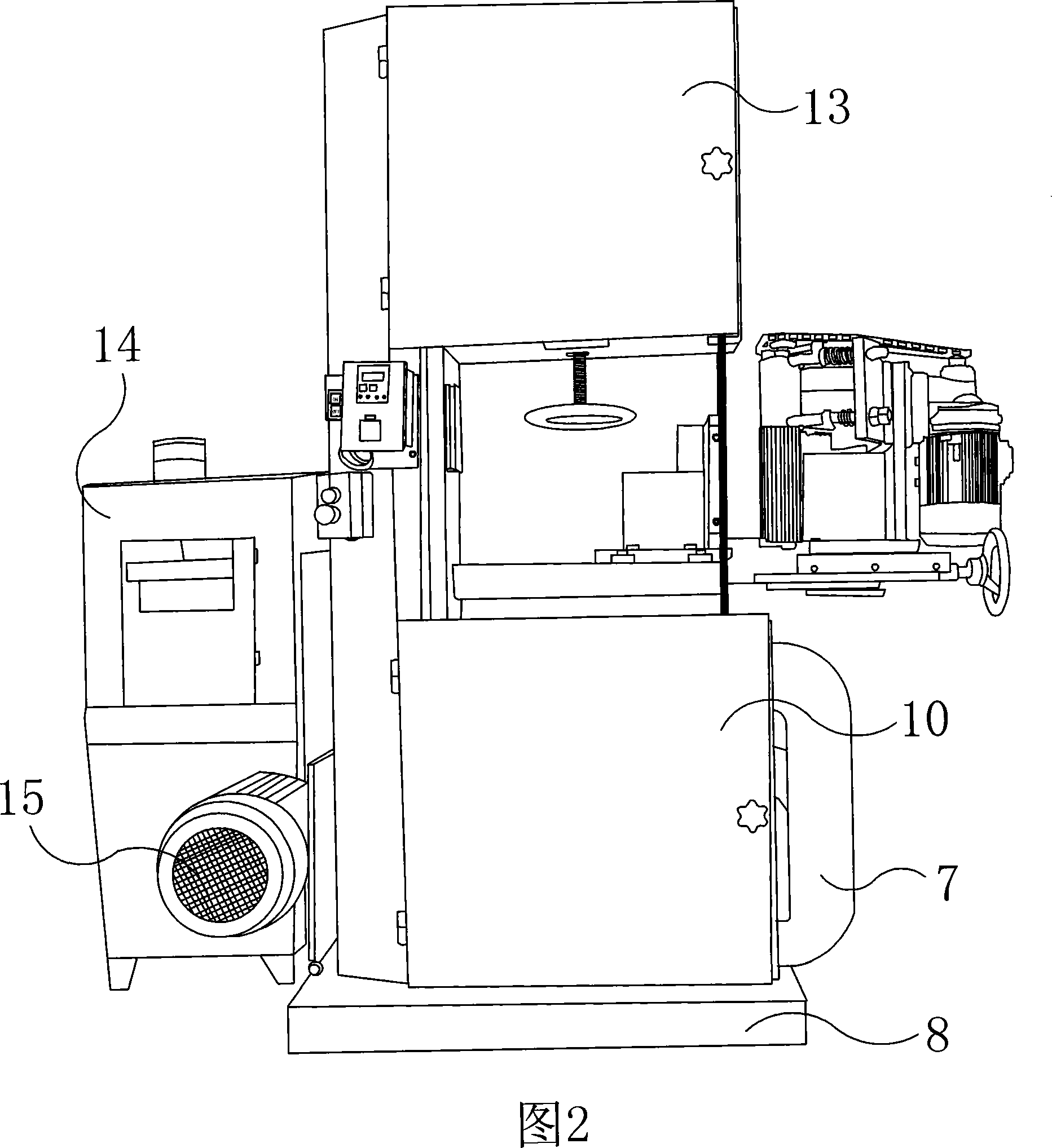

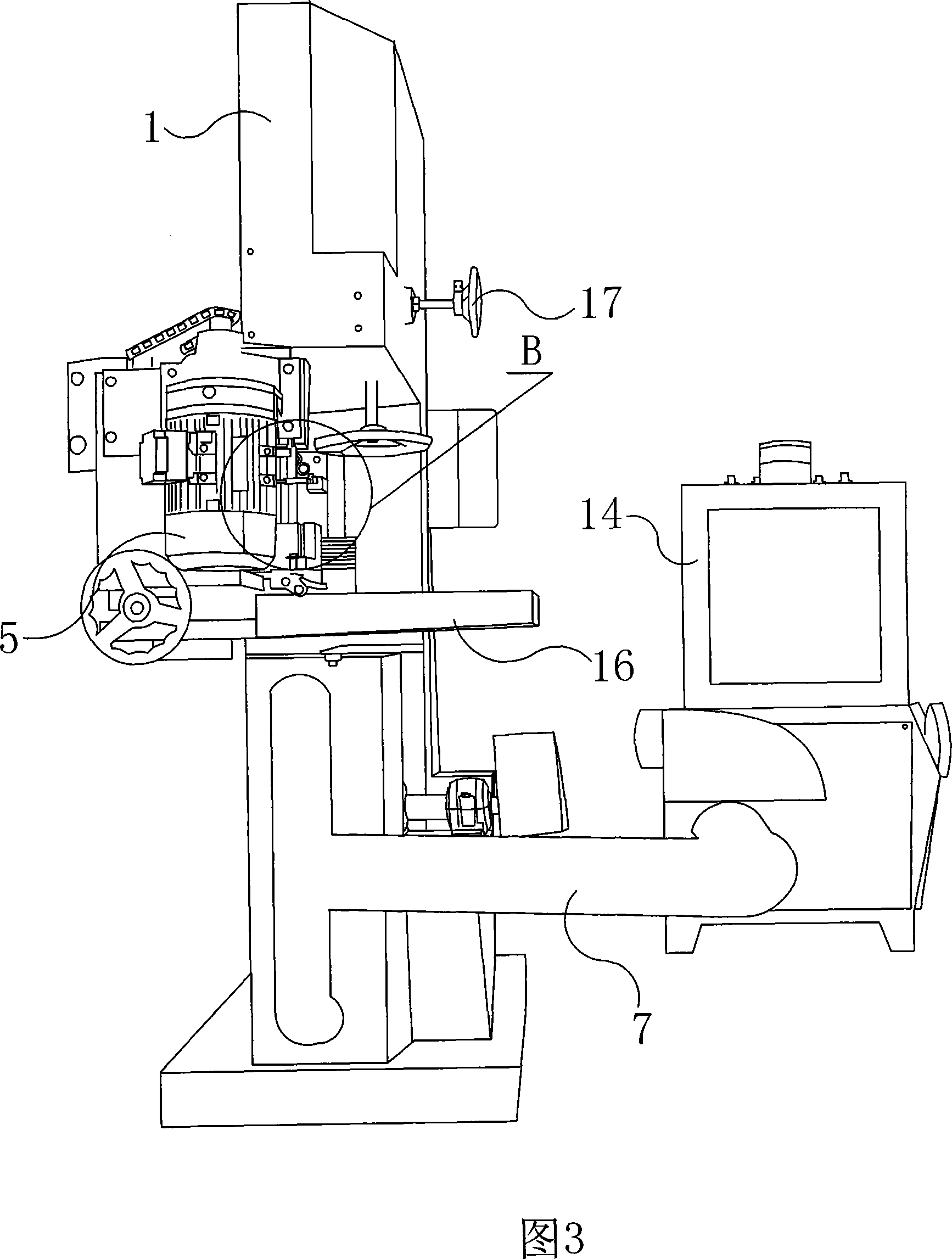

[0023] Embodiments Taking wood processing as an example, according to the specific thickness requirements of wood sawing, the inner wheel 28, middle wheel 29, and outer wheel 30 of different diameters and surface diameters of the passive saw wheel group 2 are equipped with corresponding bearings, and the frame 1 is installed in sequence. On the shaft 31 of the upper part. Active saw wheel group 9 and passive saw wheel group corresponding inner wheel, middle wheel, outer wheel of diameter surface diameter are installed successively on the axle of frame bottom, are fixed by pin. Three saw blades 12 are respectively connected to the inner wheel, the middle wheel and the outer wheel of the upper and lower parts of the frame. The tightness of connection is regulated by the passive saw wheel group vertical direction adjustment wheel 3 on the frame, and the angle is regulated by the passive saw wheel group angle adjustment wheel 17.

[0024] Loosen the screw 27, adjust the support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com