Method for confirming pipe joint width and pipe joint

A pipe joint and width technology, applied in the field of pipe joints, can solve problems such as axial movement between pipe joints and water pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

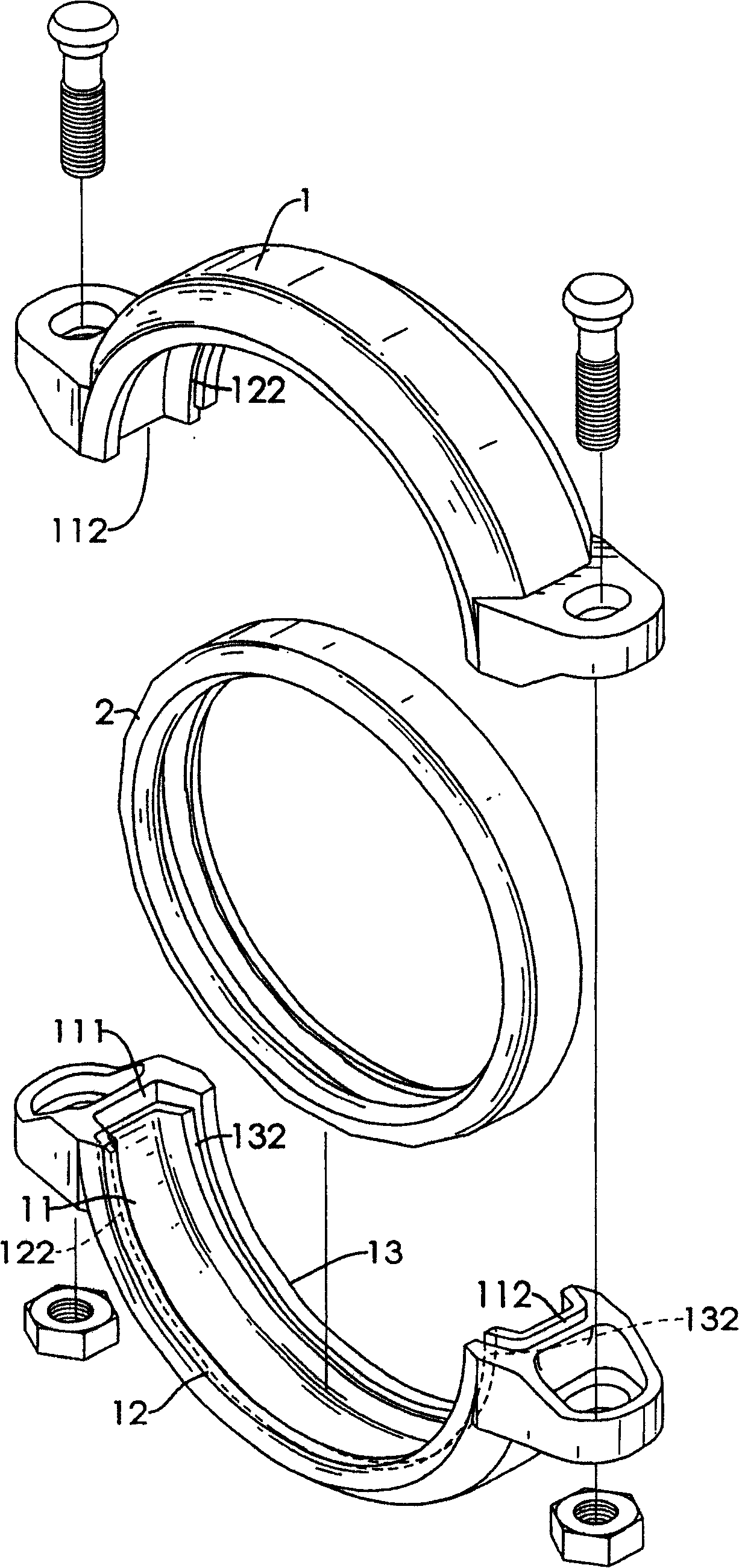

[0023] See figure 1 , The pipe joint made by the present invention is composed of two shells 1 with a semicircular section and a gasket 2 sandwiched between the two shells 1 . The shape of the pipe joint is the same as that of a general traditional pipe joint. It also has a perforation at the end for combination, and a combination of a screw and a nut for fixing the two semicircular shells. Since the structure here is the same traditional pipe joint, it will not be described in detail.

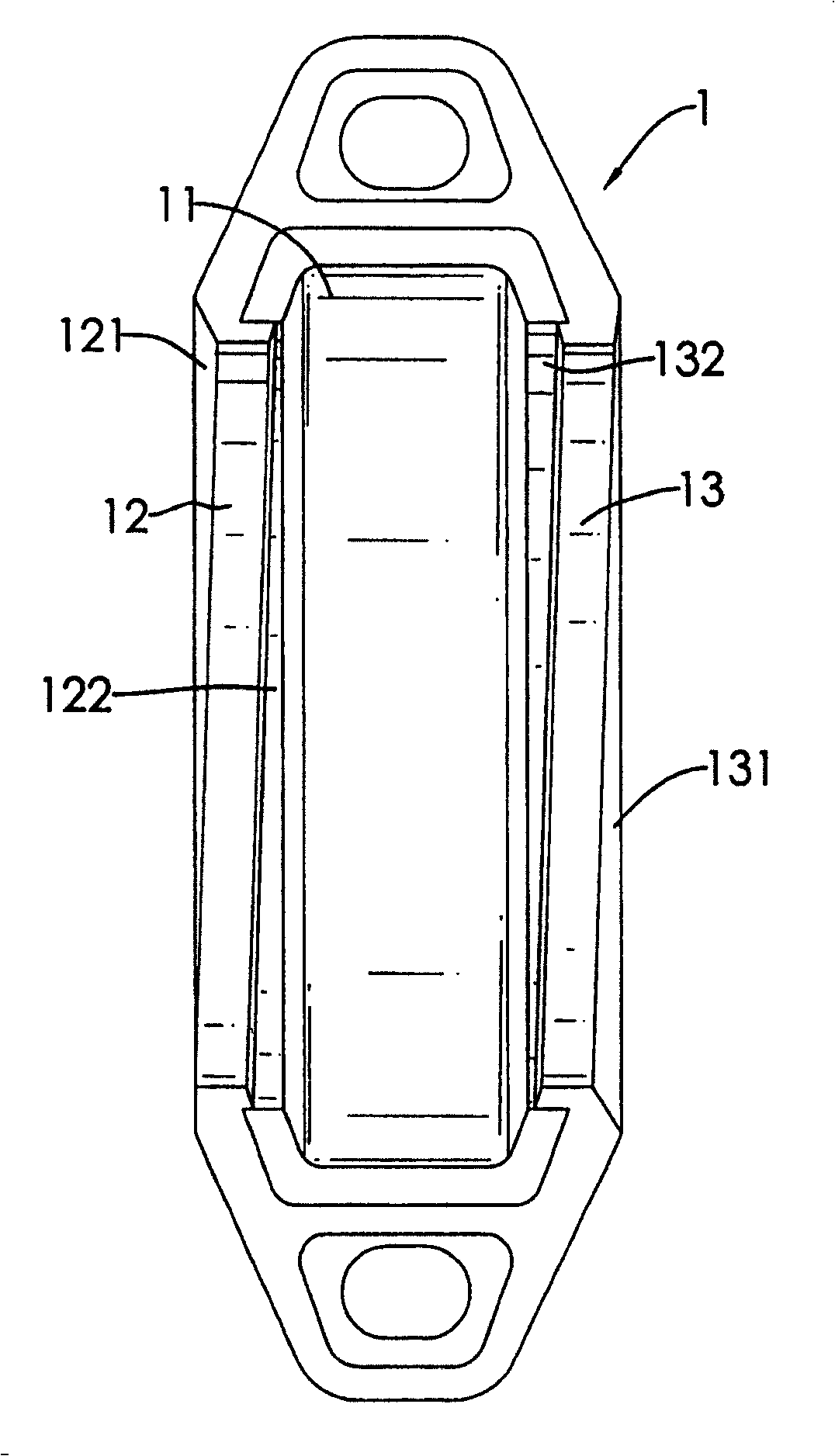

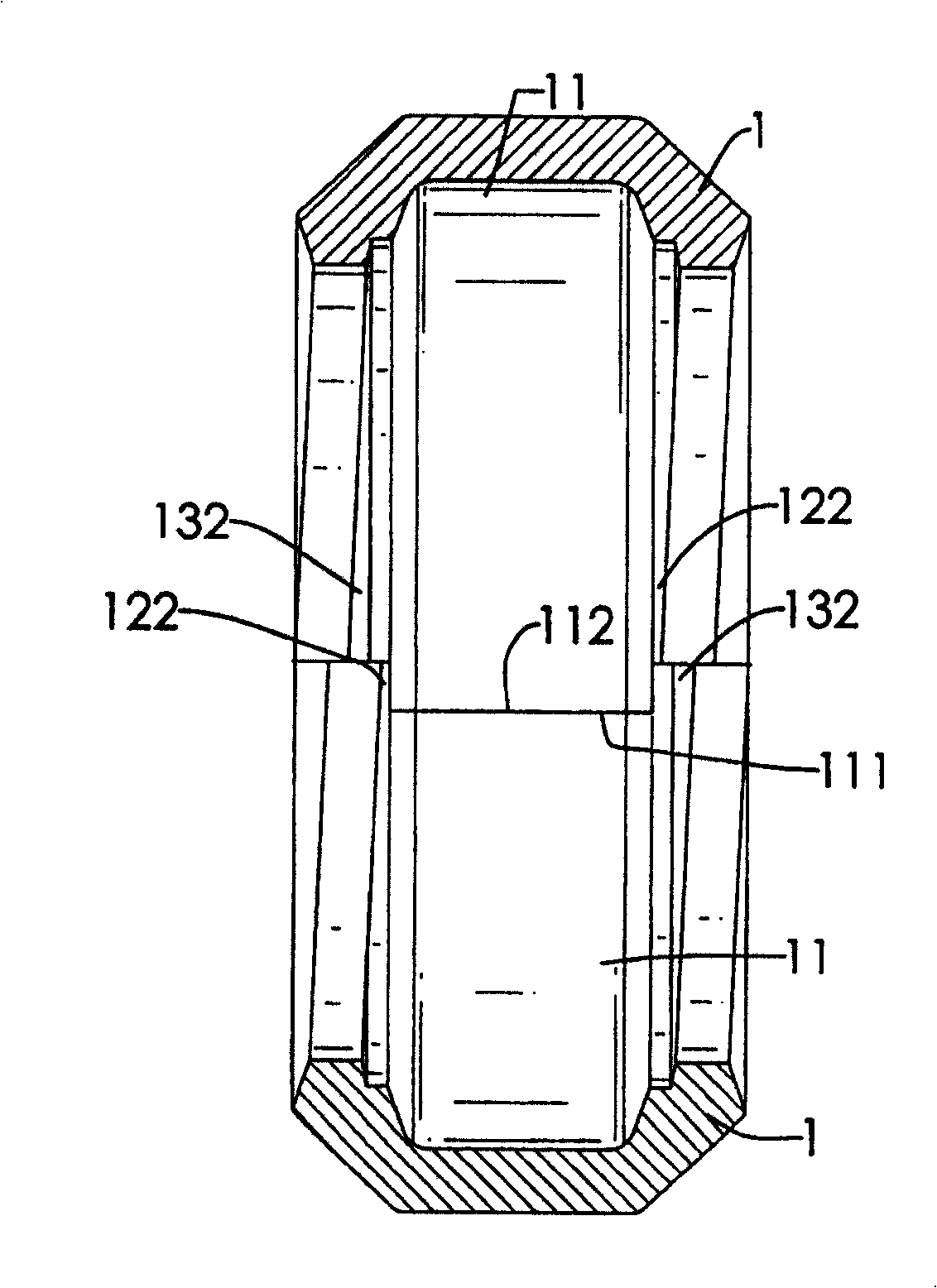

[0024] The inner surface of the first casing 1 is provided with a gasket groove 11 which can accommodate the sealing gasket 2, and a first side tooth 12 and a second side are respectively provided at the opposite side surfaces of the gasket groove 11. tooth 13. A notch 111 and a tongue 112 are respectively formed at both ends of the spacer groove 11; The combined device when the shells 1 are combined.

[0025] see you again figure 2 as well as image 3 with Figure 3A , the first tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com