A method to increase production rate of a continuous mixer or extruder

一种混合机、挤压机的技术,应用在连续混合机或挤压机进行加工领域,能够解决温度控制难以实现等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] In the following examples, melt index (MI) was measured by ASTM-D1238 and density was measured by ASTM D-792 at 190°C and 2.16 kg.

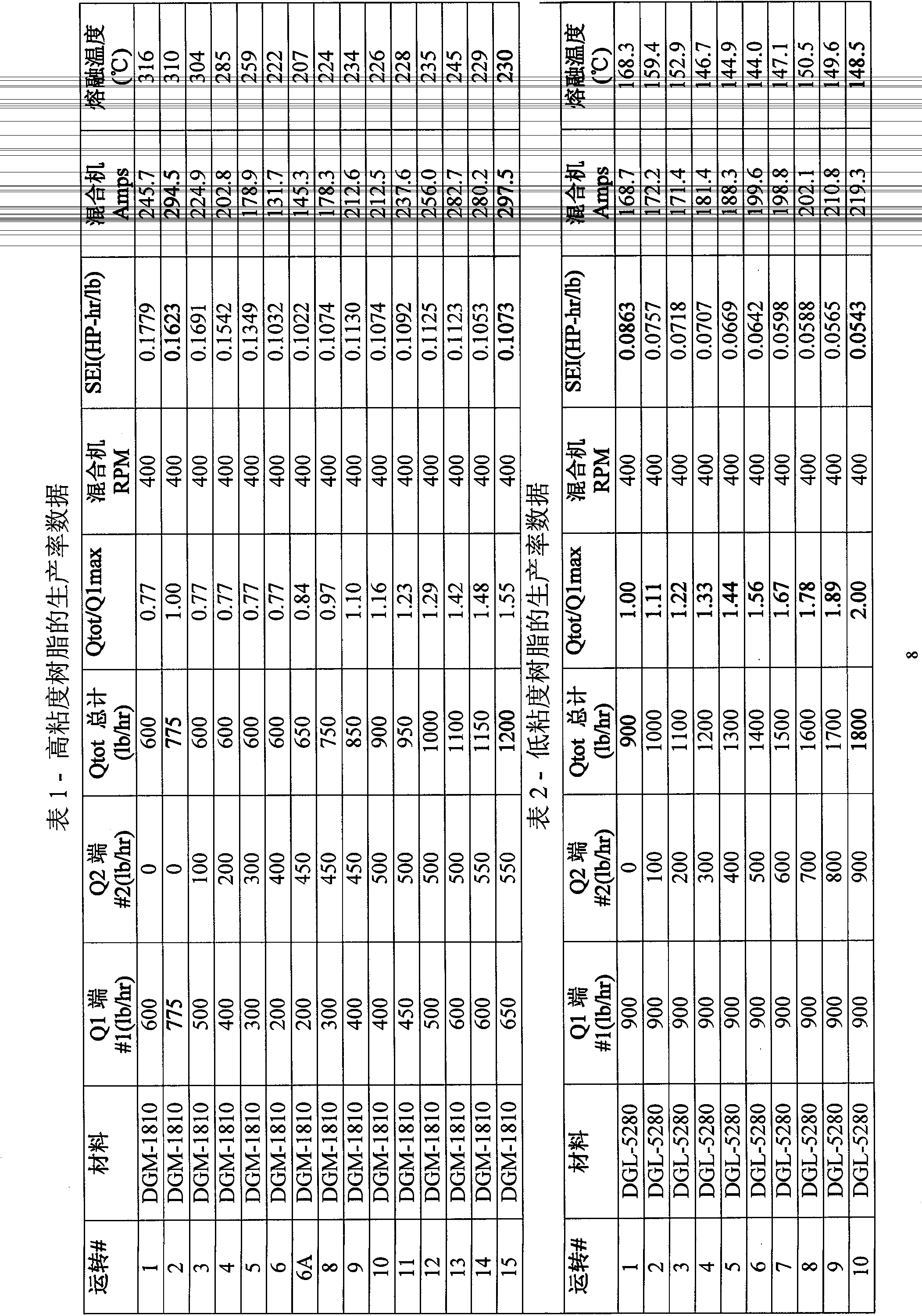

[0019] The concept of the present invention is in a two-stage Farrel TM Tests were carried out on a mixer, where the vented end was used as the second feed end, resulting in the results shown in Tables 1 and 2. In a two-stage Farrel with two feed ends and a two-stage mixing rotor TM 4”FCM TM experiment on. Each rotor has a first stage comprising an auger feed section followed by a mixing section. The second stage is the second stage portion of the rotor which was originally designed to improve ventilation and degassing and to improve additional mixing prior to polymer discharge.

[0020] As shown in Table 1, for high viscosity resin (DGM-1810 polyethylene (density 0.918g / cm 3 , MI is 1.0g / 10min, melting point is 121.2°C))—this is a representative intermediate gas phase resin—when using a single feed end, the maximum production rate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com