Use of a diester to improve the Anti-wear properties of a lubricant composition

A technology for lubricating compositions and uses, applied in the field of lubricating compositions, can solve problems such as damage to post-processing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

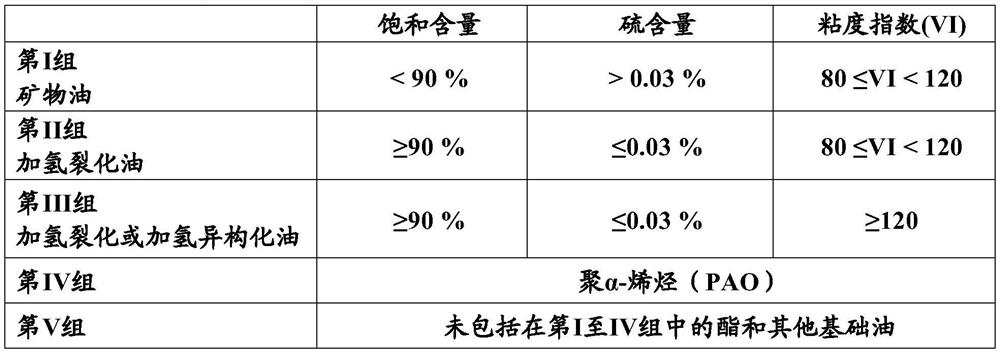

Image

Examples

Embodiment 1

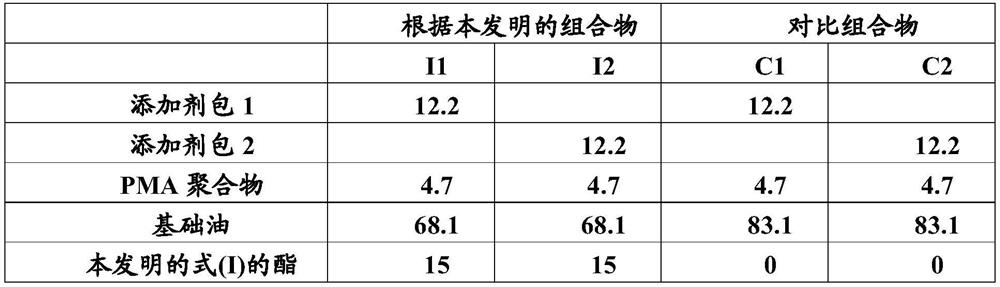

[0193] Preparation of Lubricating Compositions Comprising the Diesters Claimed According to the Invention and Comparative Compositions

[0194] The lubricating compositions (I1 and I2) of the present invention using the diester of formula (I) and the lubricating compositions without the diester of formula (I) were formulated using the components and amounts (expressed in weight percent) indicated in Table 1 below. Comparative compositions (C1 and C2).

[0195] The lubricating composition is obtained by simply mixing the following components at room temperature:

[0196] - Base oils of group III (KV100=4.2 mm2 / s, KV40=19.1 mm2 / s, VI is 126), available for example from the company SK Lubricantes under the trade name 4 commercially available,

[0197] - Conventional additive package 1 comprising antiwear additives (bis[O,O-bis(2-ethylhexyl)] and bis(dithiophosphate)zinc, for example under the name 269R), antioxidants, friction modifiers, dispersants and detergents,

[019...

Embodiment 2

[0209] Evaluation of anti-wear performance

[0210] Evaluation method

[0211] This evaluation is based on a procedure according to standard ASTM D2670, which requires the use of a FALEX tribometer under the following test conditions.

[0212] - Specimen: FALEX steel

[0213] - Grinding time: 300s;

[0214] - Test duration: 180 minutes;

[0215] - Grinding load: 445N;

[0216] - Test load: 1335N;

[0217] - Speed: 290 rpm;

[0218] - room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com