Single station garment standing collar steaming and ironing machine

A single-station steam ironing machine technology, applied to washing devices, wrinkle-removing and flattening equipment, textiles and papermaking, etc., can solve the problems of limited and unsightly user workshop space, and achieve the goal of reducing height and shortening space distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

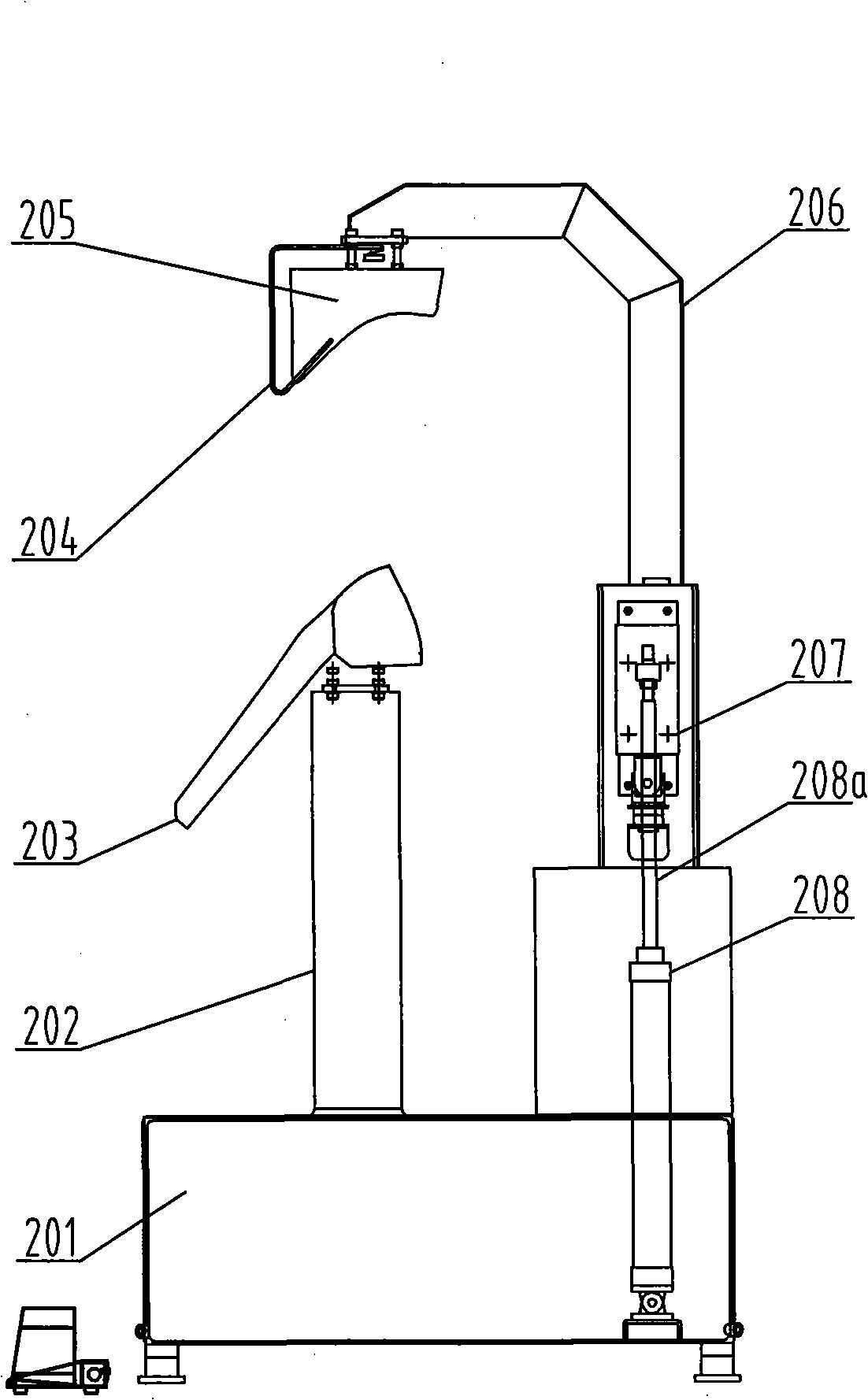

[0013] According to attached figure 2 and 3 , a schematic structural view of a single-station collar steamer for garments of the present invention, which has a fixed frame 201, a lower mold base 202 is fixed on the frame 201 with bolts, and a lower mold 203 is fixed on the lower mold base 202 with bolts;

[0014] The upper mold 205 is fixed on the upper mold frame 206 with bolts, and the upper mold is provided with a safety bar 204 . The upper mold frame is equipped with a linear guide rail, and this linear guide rail cooperates with the linear slide rail mounted on the frame 201 to make the upper mold move up and down on this track. Upper mold frame is connected on the cylinder 208 that moves up and down by floating joint.

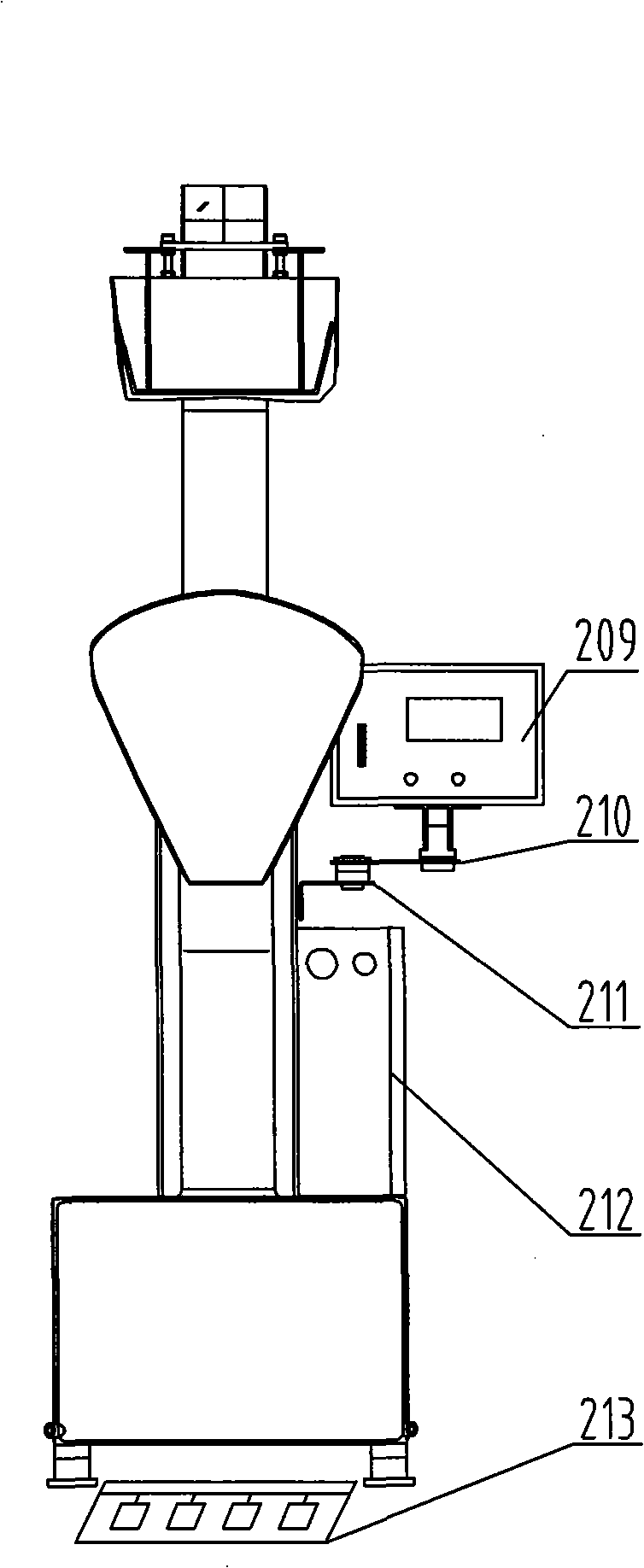

[0015] The electric control box 212 is fixed on the frame 201, the pedal switch 213 can be placed on the ground and electrically connected with the electric control box 212, the operation box 209 is fixed on the frame 201 by the connecting rod 210 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com