Concentricity detection device and its method

A technology for testing equipment and concentricity, applied to measuring devices, installation, optics, etc., can solve problems such as slow speed, error, low efficiency and precision, and achieve the effects of reducing production costs, improving efficiency, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

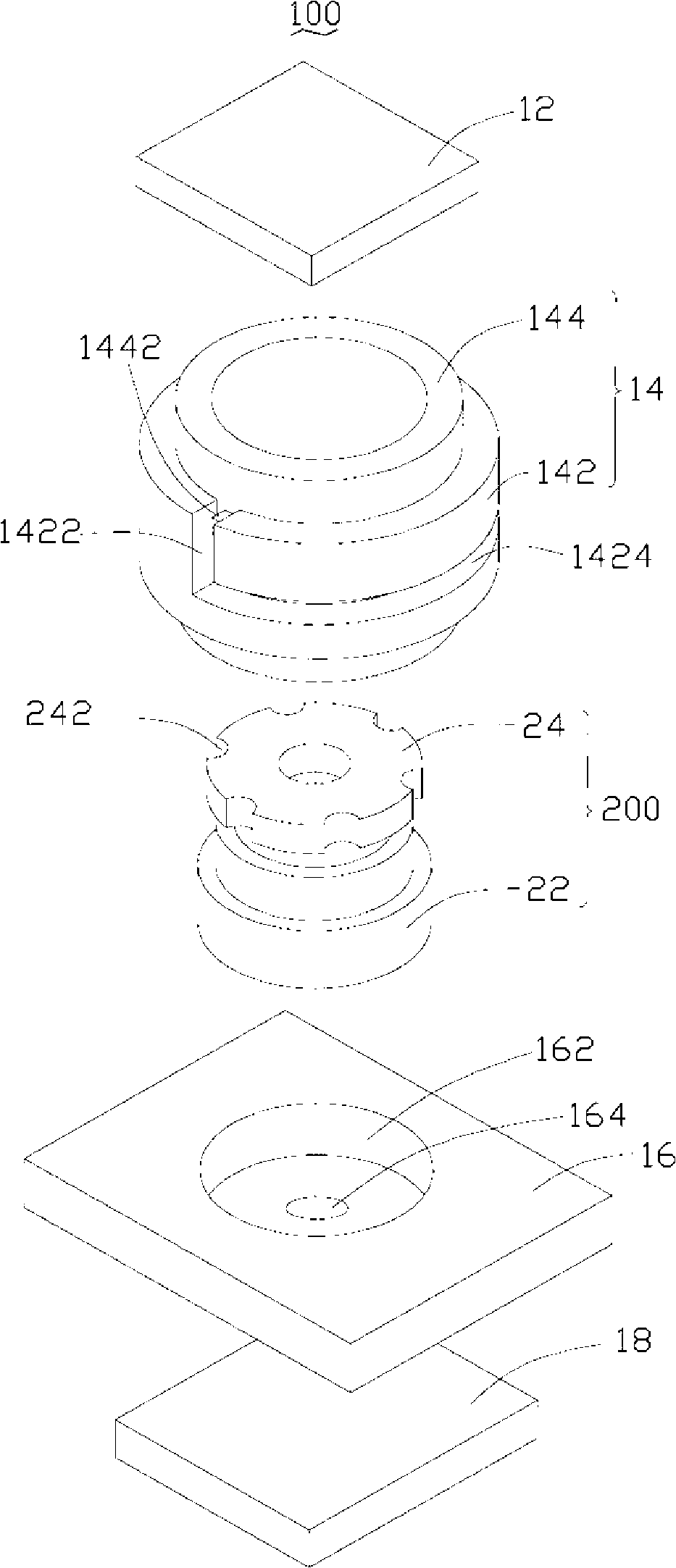

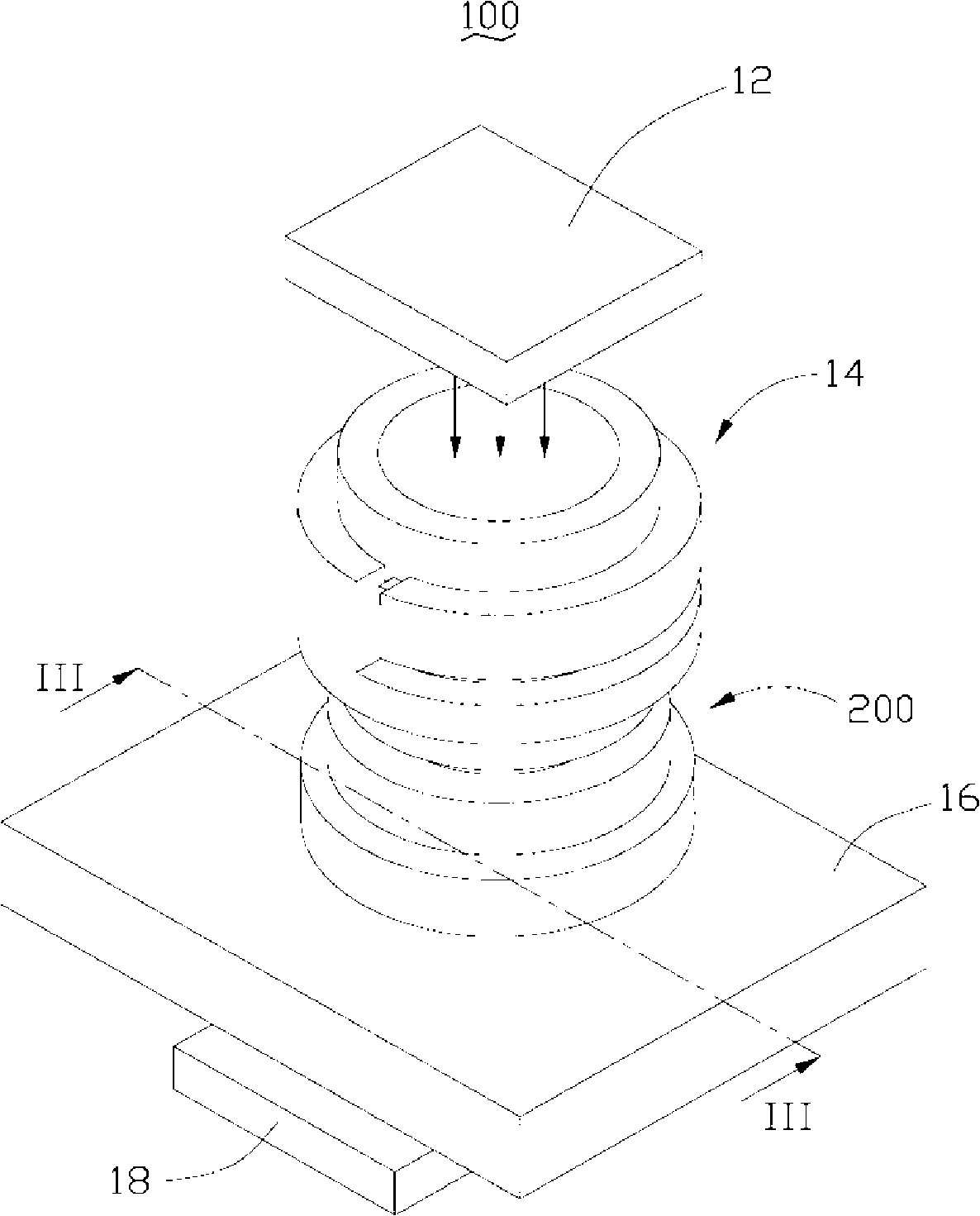

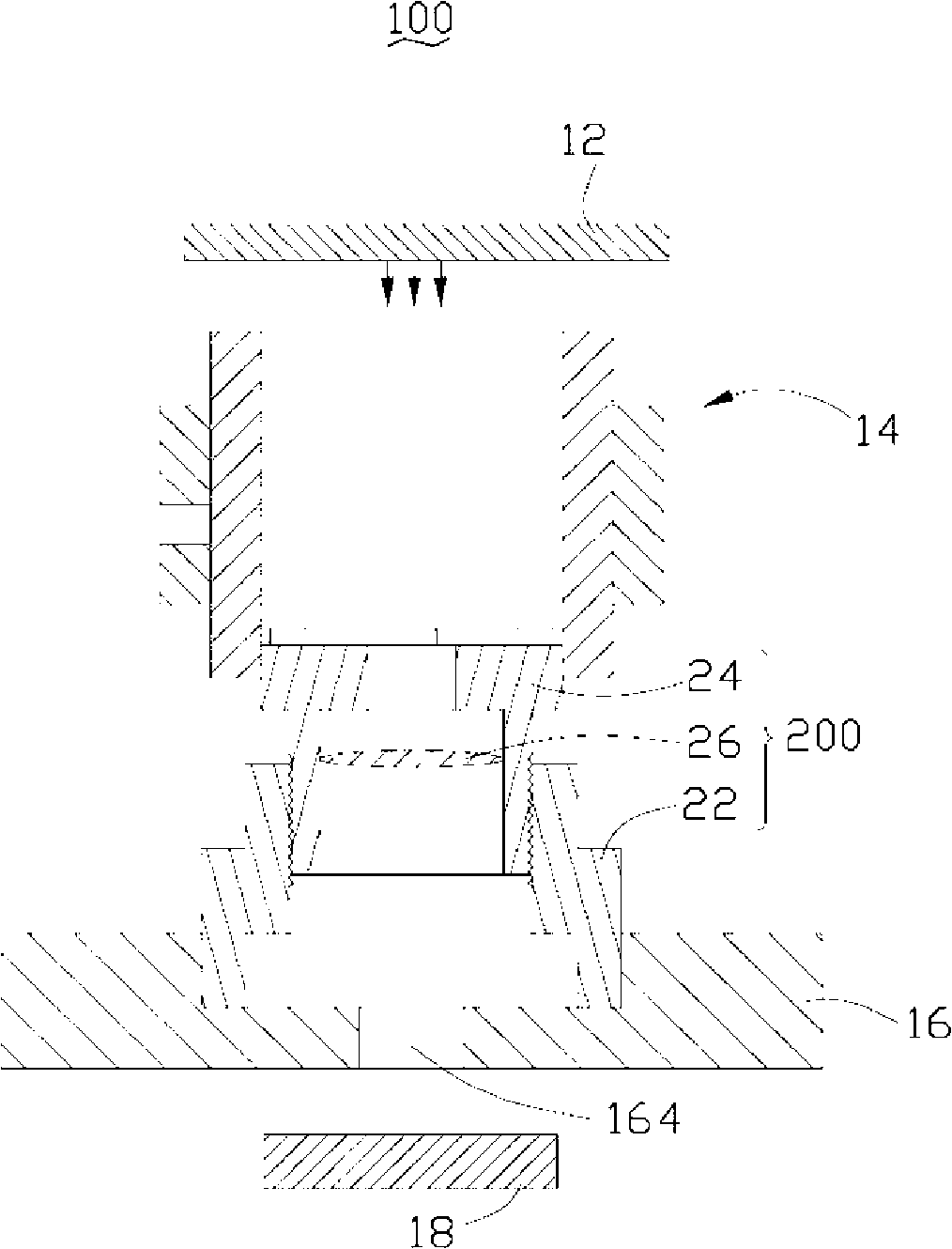

[0017] Please refer to Figure 1 to Figure 3 , is a schematic diagram of the concentricity testing device 100 and the lens module 200 to be tested according to the first embodiment of the present invention.

[0018] The lens module 200 to be tested includes a lens base 22 , a lens barrel 24 disposed in the lens mount 22 and engaged with the lens mount 22 , and at least one lens 26 disposed in the lens barrel. The concentricity detection device 100 is used to detect the axial concentricity between the lens barrel 24 and the lens base 22 after the lens barrel 24 is assembled into the lens base 22, that is, the axis of the lens barrel 24 and the lens base 22. Positional deviation between axes. The outer edge of one end of the lens barrel 24 is provided with a plurality of notches 242 , and the plurality of notches 242 are uniformly arranged on the outer edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com