Service assembly for a textile machine which produces crosswound bobbins

A technology of cross-winding bobbins and service components, which is applied in the field of service components and can solve problems such as cross-winding bobbins without yarn reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

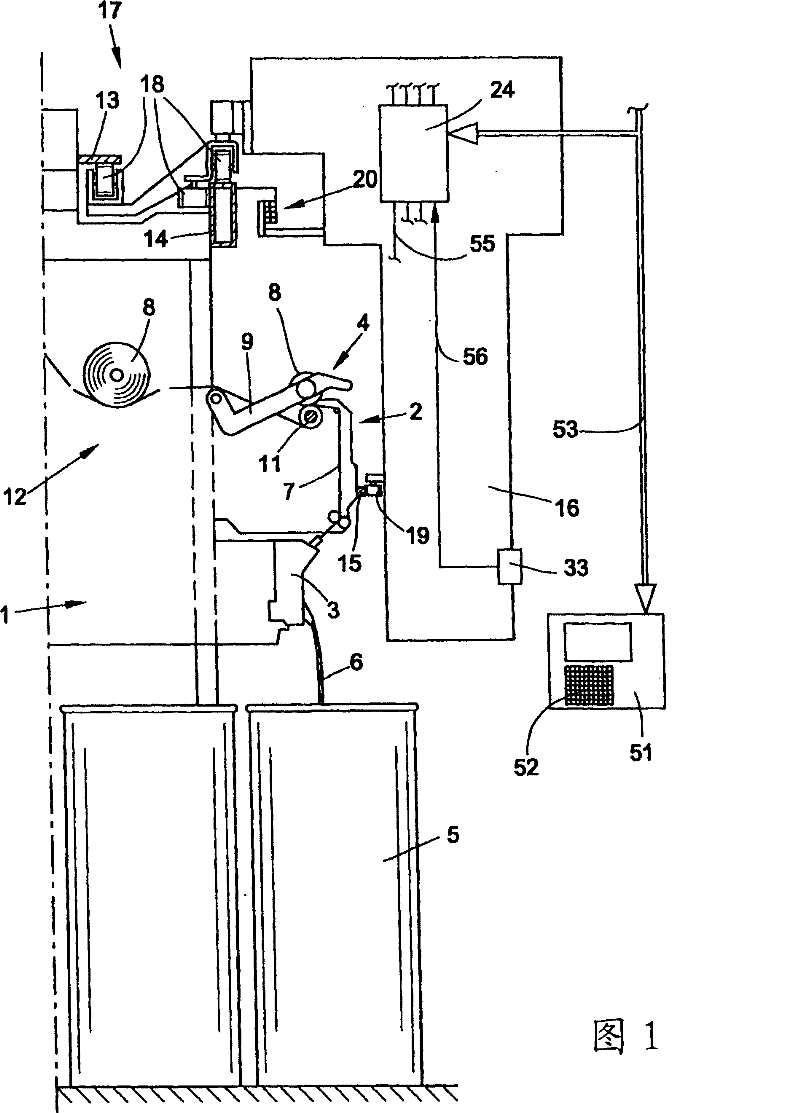

[0021] figure 1 A half of an open-end spinning machine known per se, designated by reference numeral 1, is shown in FIG. Open-end spinning machines of this type generally have a large number of workstations 2 each equipped with a spinning mechanism 3 and a winding device 4 .

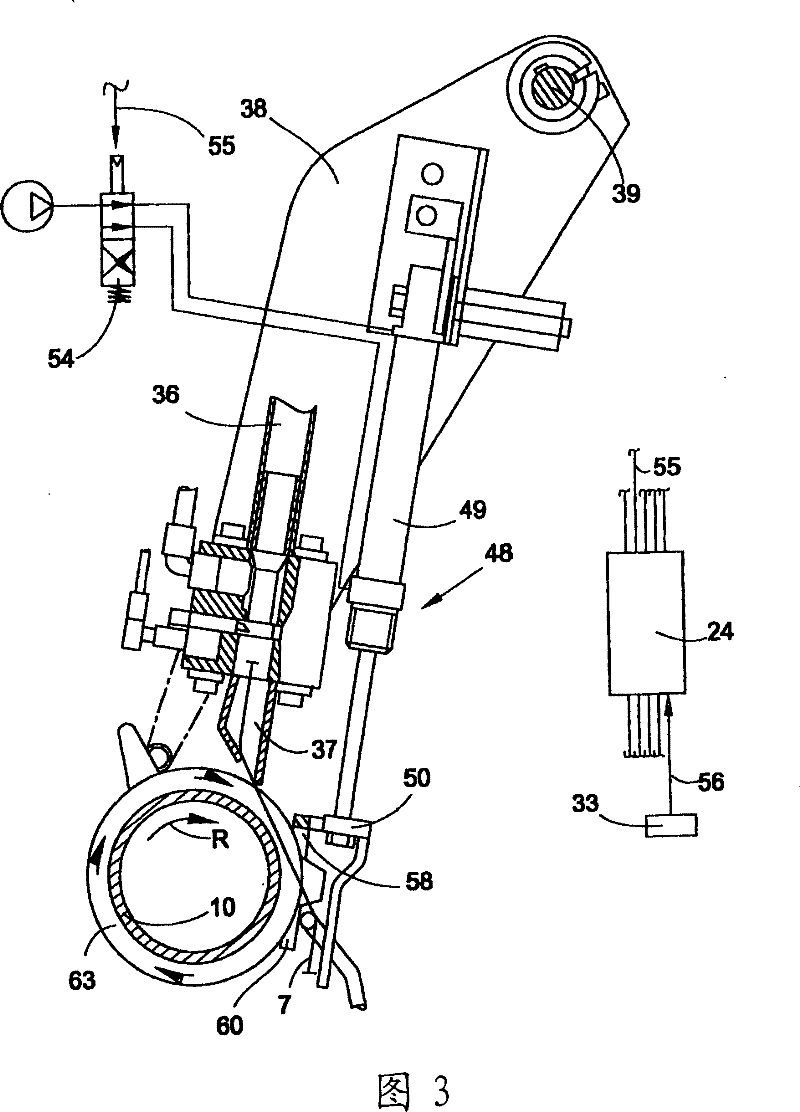

[0022] In the spinning boxes 3 , the fiber strips 6 fed to the spinning pots 5 are spun respectively to form yarns 7 , which are then wound on the winding device 4 to form cross-wound bobbins 8 . As shown, the winding device 4 is equipped in this example with a creel 9 for rotationally holding the cross-wound bobbin 10 and with a friction drive for the cross-wound bobbin 10 or cross-wound bobbin 8 The bobbin drum 11.

[0023] Most double-row open-end spinning machines 1 also frequently have between their two rows of work stations a bobbin conveyor 12 through which the completed cross-wound bobbins 8 are transported away.

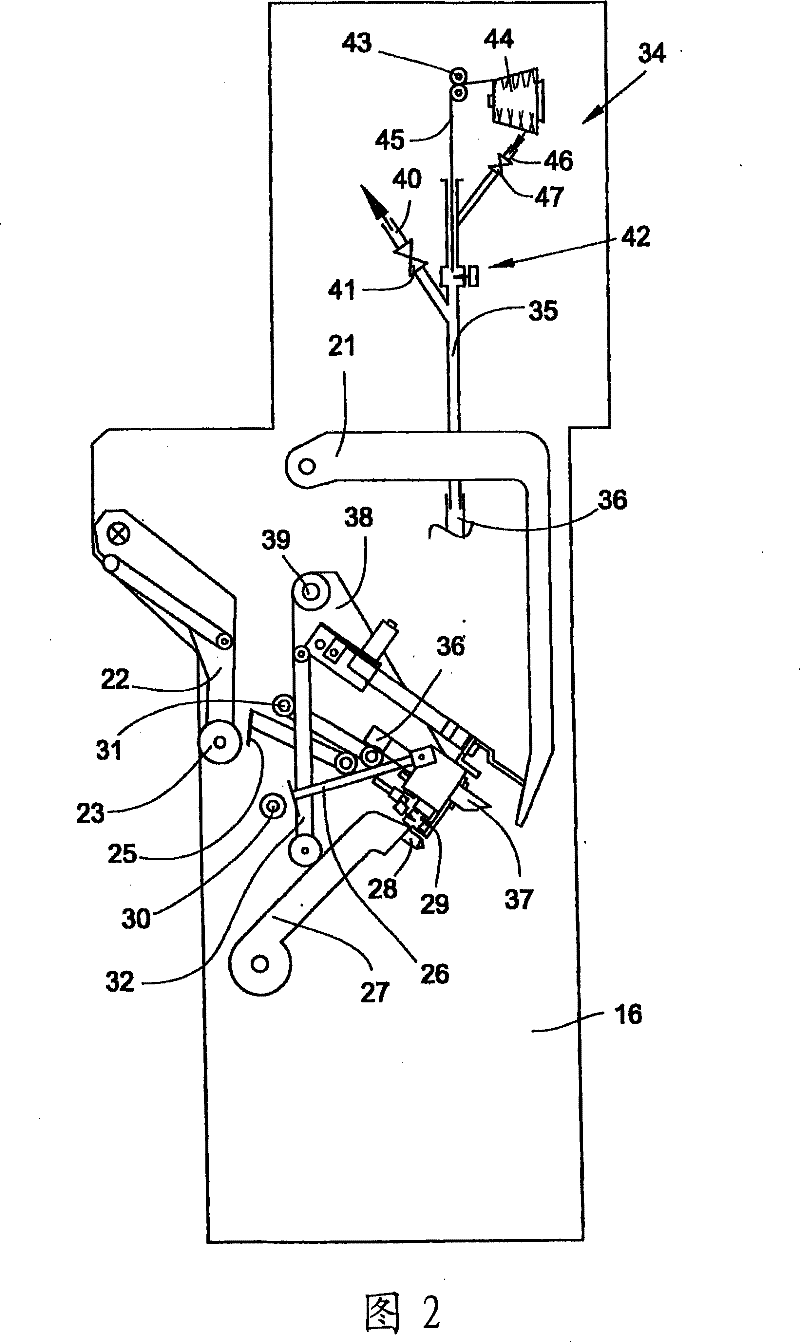

[0024] A service unit 16 , for example a so-called piecing carriage, is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com