Spanner base structure

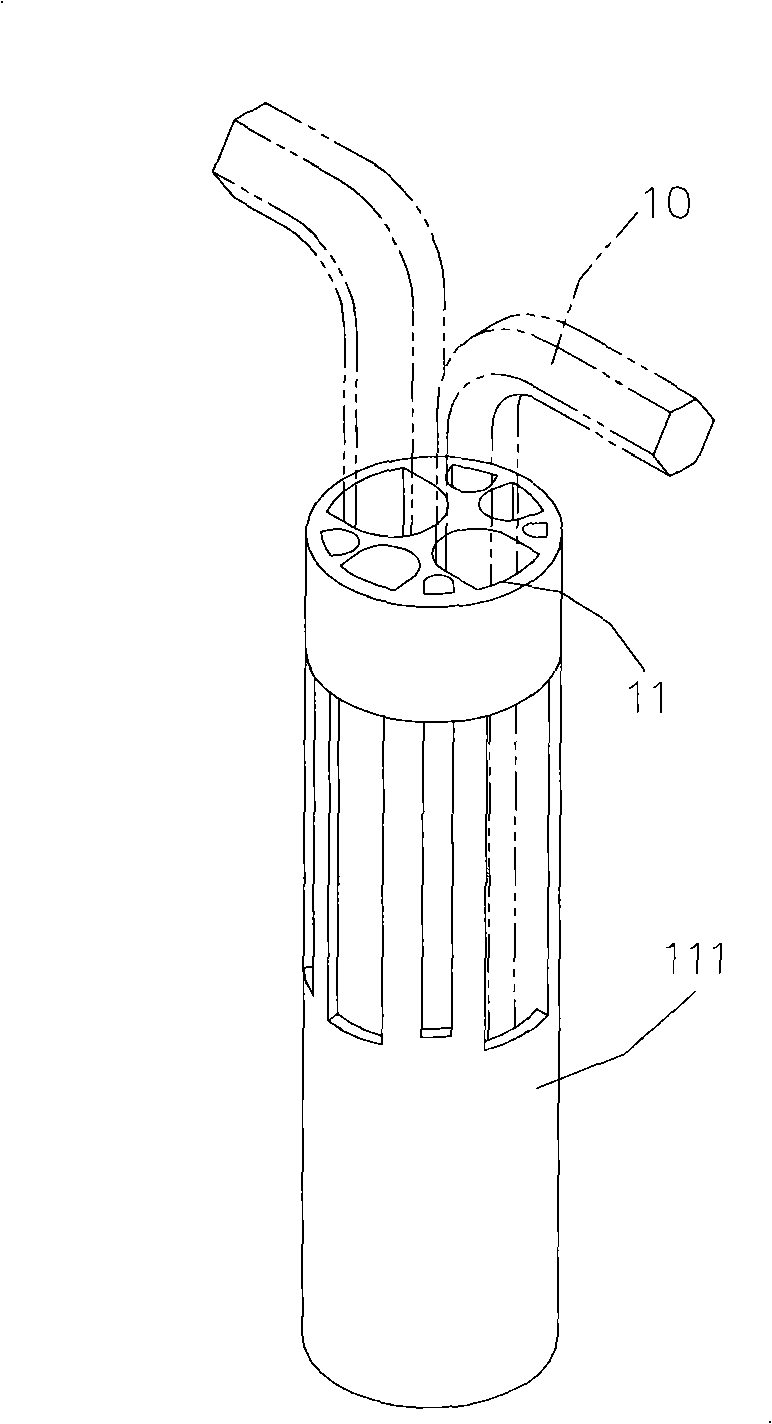

A technology of wrench and wrench lever, which is applied in the direction of wrench, wrench, screwdriver, etc. It can solve the problems of easy accidental drop, wear material, loss of friction positioning, etc., and achieve the effects of avoiding wear, effectively positioning tools, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

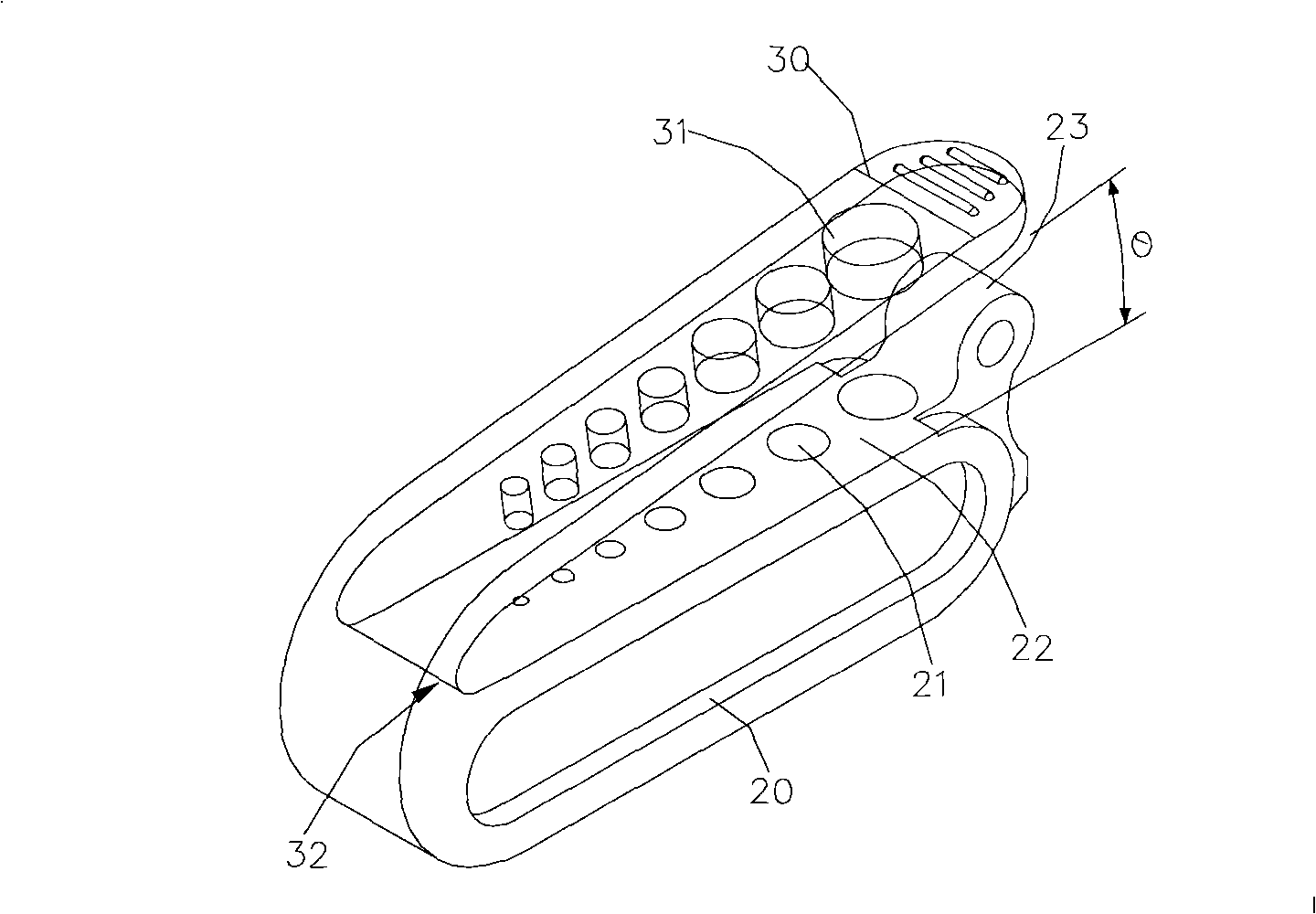

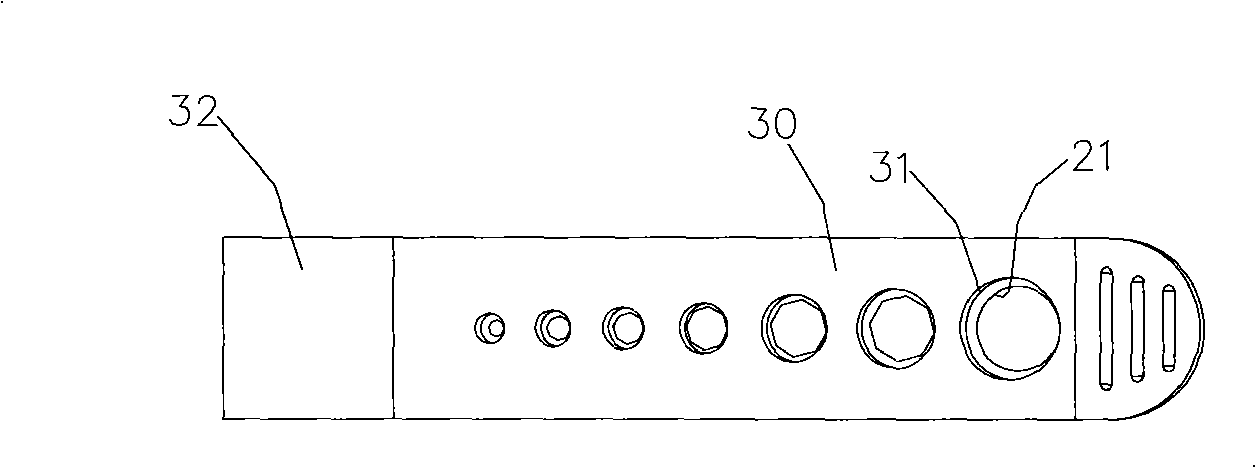

[0017] Please refer to the present invention figure 2 , image 3 ,and Figure 4 , the wrench seat structure of the present invention includes a positioning platform 20 and an outward extension arm 30, and is used with a plurality of L-shaped wrenches 40 (see Figure 5 ), its structural characteristics are:

[0018] The positioning table 20 is a one-piece assembly, and several linearly arranged through positioning holes 21 are made on a plane 22 of the positioning table 20. The shape of the positioning holes 21 corresponds to the shaft section of the L-shaped wrench 40. The positioning table 20. A protruding block 23 is made at one end of the plane 22;

[0019] The extension arm 30 is integrally connected to the other end of the plane 22 of the positioning platform 20 by the elastic section 32, and the extension arm 30 is connected to the positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com