Semi-trailer support bearing screwed cap

A semi-trailer and nut technology, which is applied in vehicle maintenance, lifting vehicle accessories, belts/chains/gears, etc., can solve problems such as increased thread bending moment and shear force, inability to maintain nut stability, and reduced lifting capacity of outriggers , to achieve the effect of reducing weight, increasing the ability to resist rotational torque, and improving lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

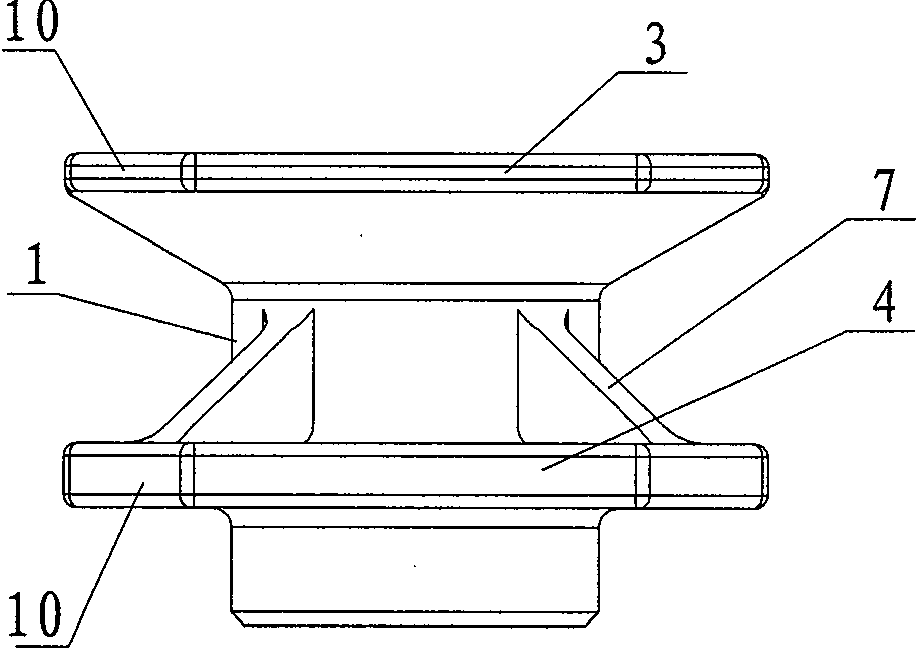

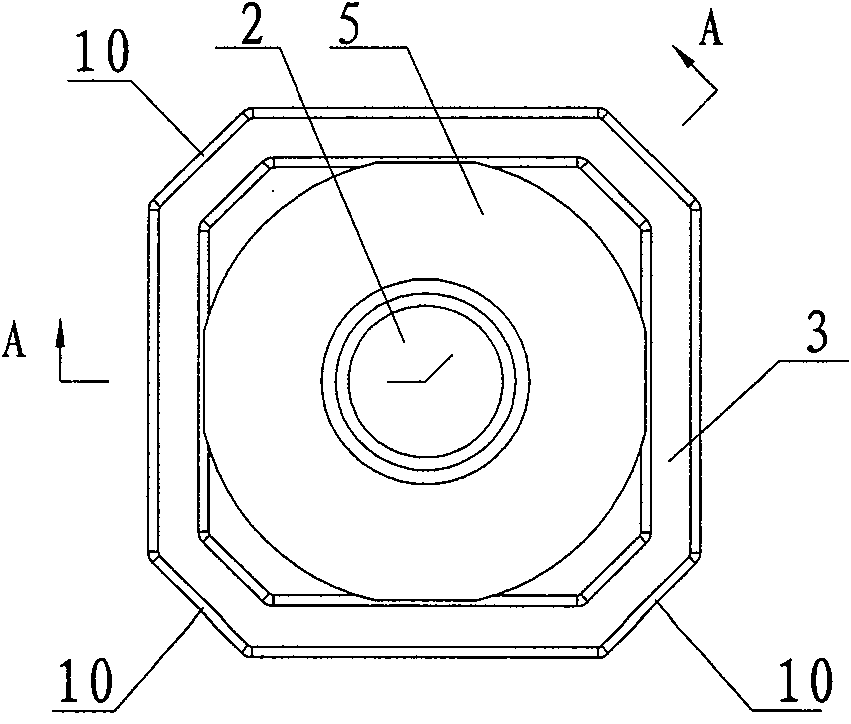

[0031] see Figure 1 to Figure 5 As shown, this embodiment is the best embodiment of the bearing nut for the outrigger of the semi-trailer, which includes a threaded hole 2 arranged on the nut cylinder 1 and connected to both ends of the nut. The nut is a two-layer structure consisting of an upper layer 3 and a lower layer 4. Both layers are squares with the same cut corner 10. The sides of the squares are equal in length, and the projections of the outer contours of the two layers along the axis of the cylinder 1 coincide. The corner cutting 10 of the square is a straight line cutting corner, so as to avoid the rounded corner position of the square tube 8 . When the screw mandrel rotates, at least 5 to 6 of the 8 corners of the double-layer square nut are in contact with the inner wall of the square tube 8 at the same time, so as to increase the ability of the nut to resist the rotational torque.

[0032] The upper layer 3 of the nut is provided with a funnel-shaped oil cup ...

no. 2 example

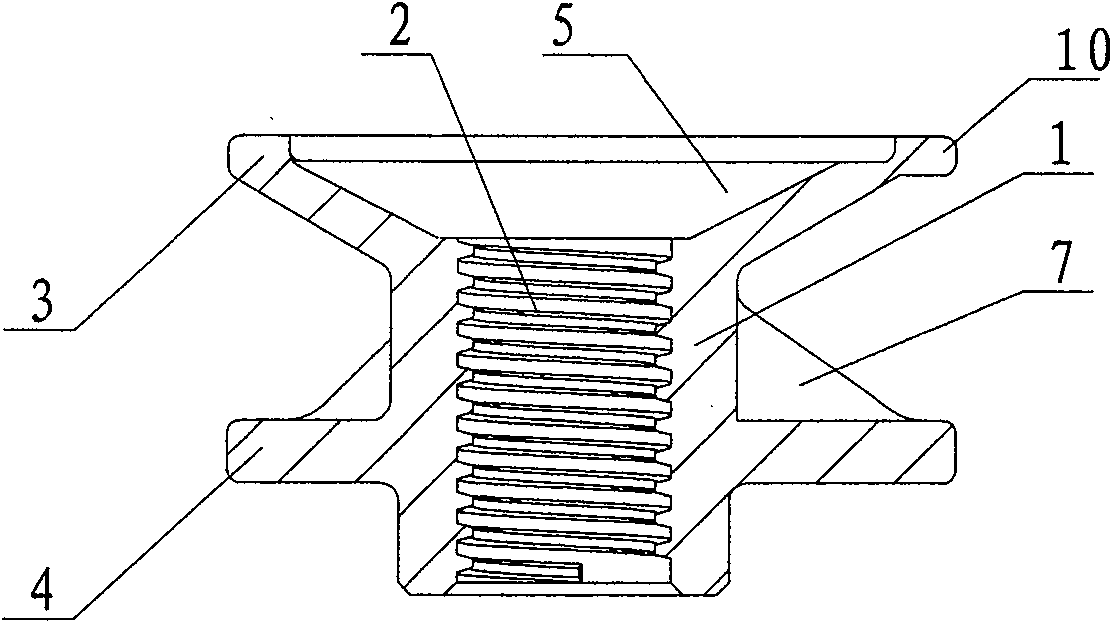

[0036] see Figure 6 to Figure 9 As shown, this embodiment is another embodiment of the bearing nut for the outrigger of the semi-trailer. Its basic structure is consistent with that of the first embodiment, so it is omitted here. The difference is:

[0037] The corners cut at the four corners of the nut upper layer 3 and the lower layer 4 are arc cut corners, which are also for avoiding the rounded corners of the square tube 8 .

[0038] The reinforcing ribs 7 between the upper layer 3 and the lower layer 4 are quadrilaterals, eight in number, uniformly distributed in the circumferential direction, and the four alternate reinforcing ribs 7 are facing the four corners, and the top edge of the reinforcing rib 7 is connected with the upper layer 3, and the bottom edge It is connected with the lower layer 4, and one side is connected with the column body 1.

[0039] The upper stratum 3 of the nut is provided with an oil storage groove 5' communicated with the threaded hole 2. Th...

no. 3 example

[0041] see Figure 10 As shown, this embodiment is the third embodiment of the bearing nut for the outrigger of the semi-trailer. The basic structure of this embodiment is the same as that of the first embodiment, so it will be omitted here. The difference is:

[0042]The nut of this embodiment is a three-layer structure consisting of an upper layer 3, an intermediate layer 6, and a lower layer 4. The three layers are all squares with the same cut angle 10. The sides of the three layers are equal in length, and their outer contours are along the axis of the cylinder 1. The projection coincides, and when the screw is rotated, the three layers of the nut may be in contact with the square tube, so as to keep the work stable and increase the nut's ability to resist the rotating torque. The reinforcing rib 7 is arranged between the column body 1 and the lower layer 4, and the reinforcing rib 7 is consistent with the embodiment 1, so it is omitted here. Due to the three-layer struc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap