Method for producing clothing lattice type plate

A grid, centerline technology, applied in the field of clothing cutting, can solve the problem of not getting rid of empirical formulas, etc., and achieve the effect of shortening design time, simple and intuitive clothing structure design, and reducing design difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

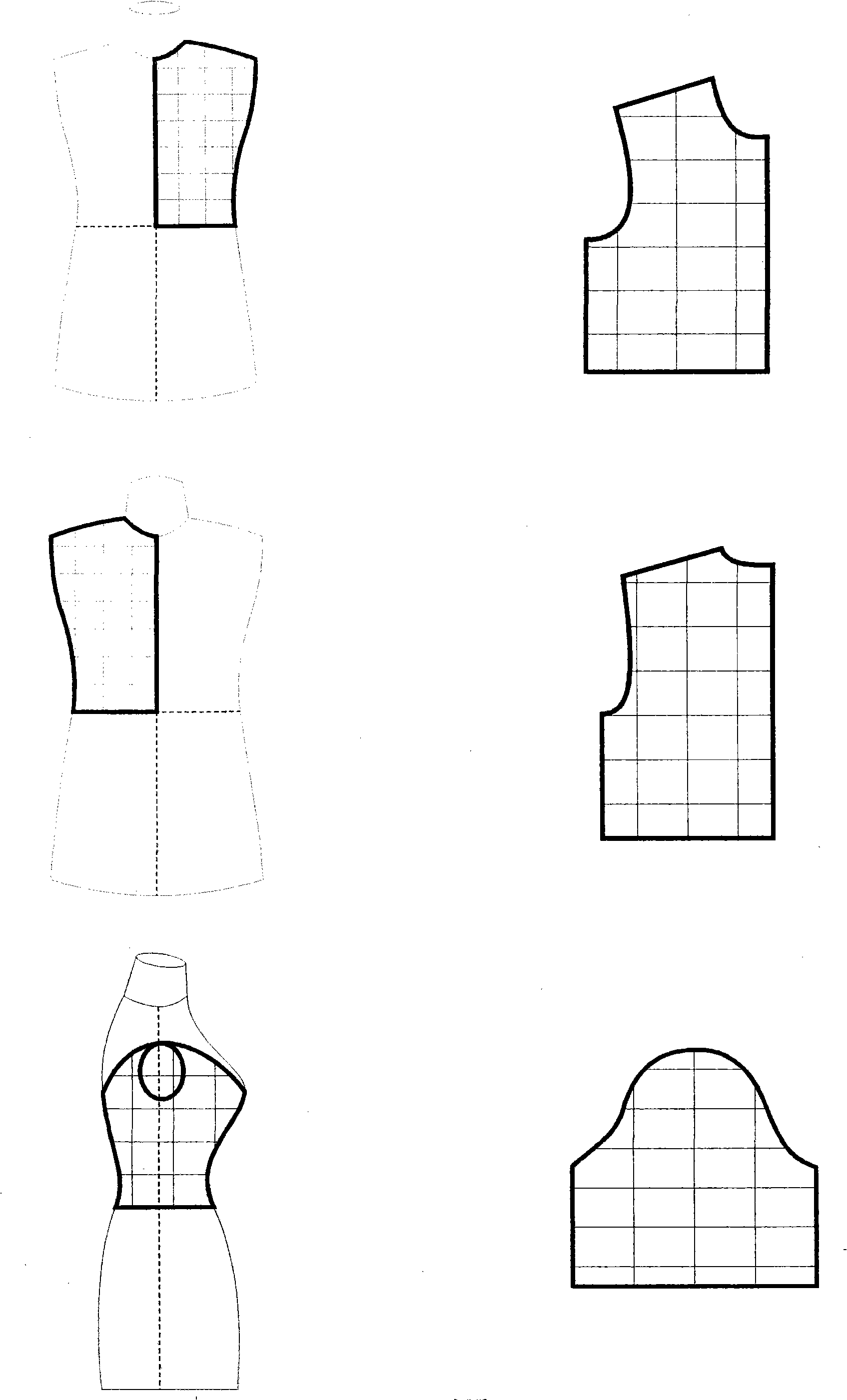

[0011] 1. Design finished garment specifications according to the style and shape

[0012] First, examine and understand the renderings: determine the size of each control part of the finished garment according to the style of the garment, the position and function of the dividing line, the characteristics of the fabric and dressing of the garment, the occasion and habits of dressing, and other factors.

[0013] Take a certain style of clothing of size 160 / 84A as an example:

[0014] Net body control part data (cm) Finished garment specification (cm)

[0015] Cervical point sitting height 62.5 clothing length 66

[0016] Arm Length 50.5 Sleeve Length 25

[0017] Bust 84 Bust 96

[0018] Overall Shoulder Width 39.4 Overall Shoulder Width 40

[0020] Hips 90 Hips 96

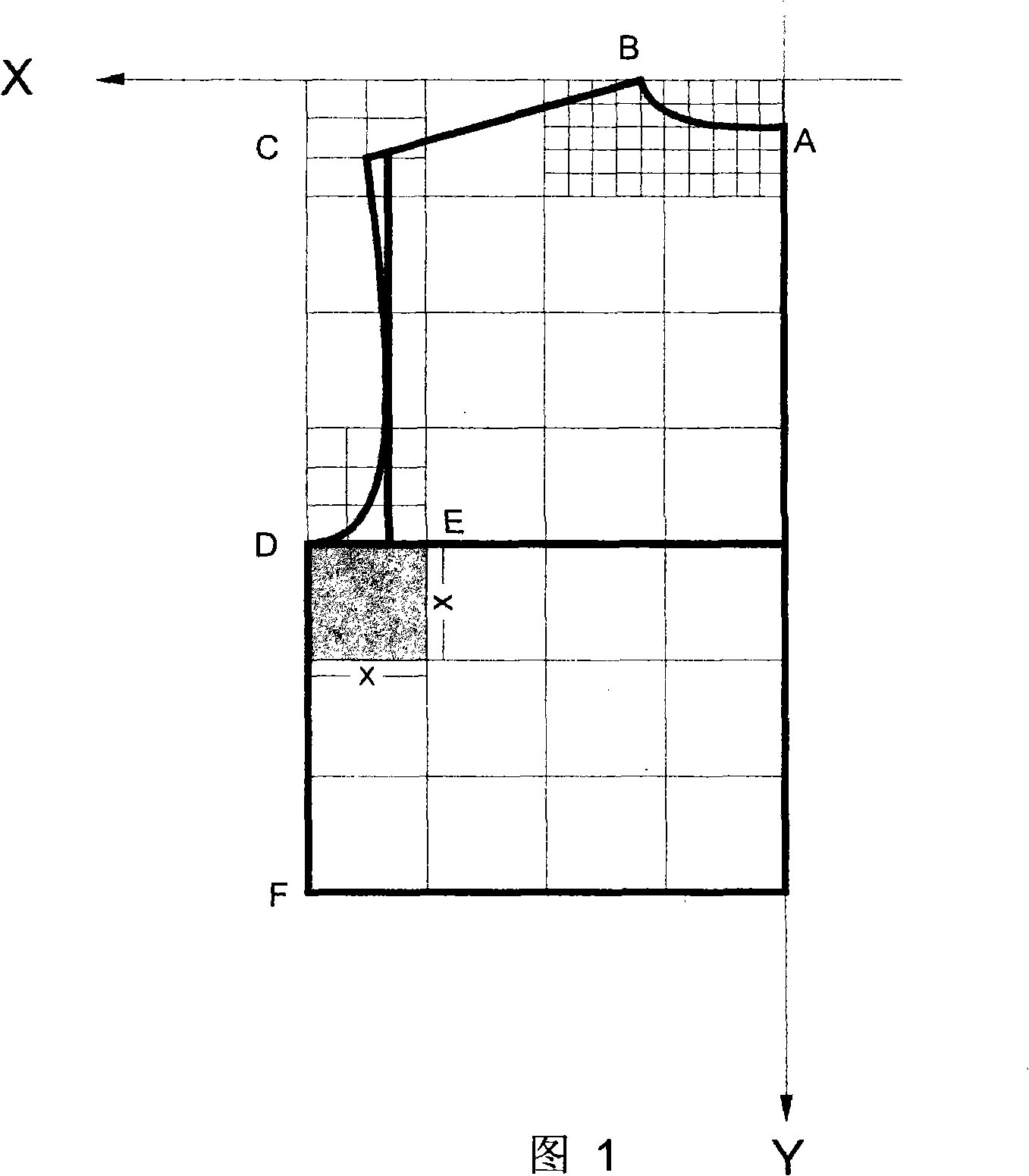

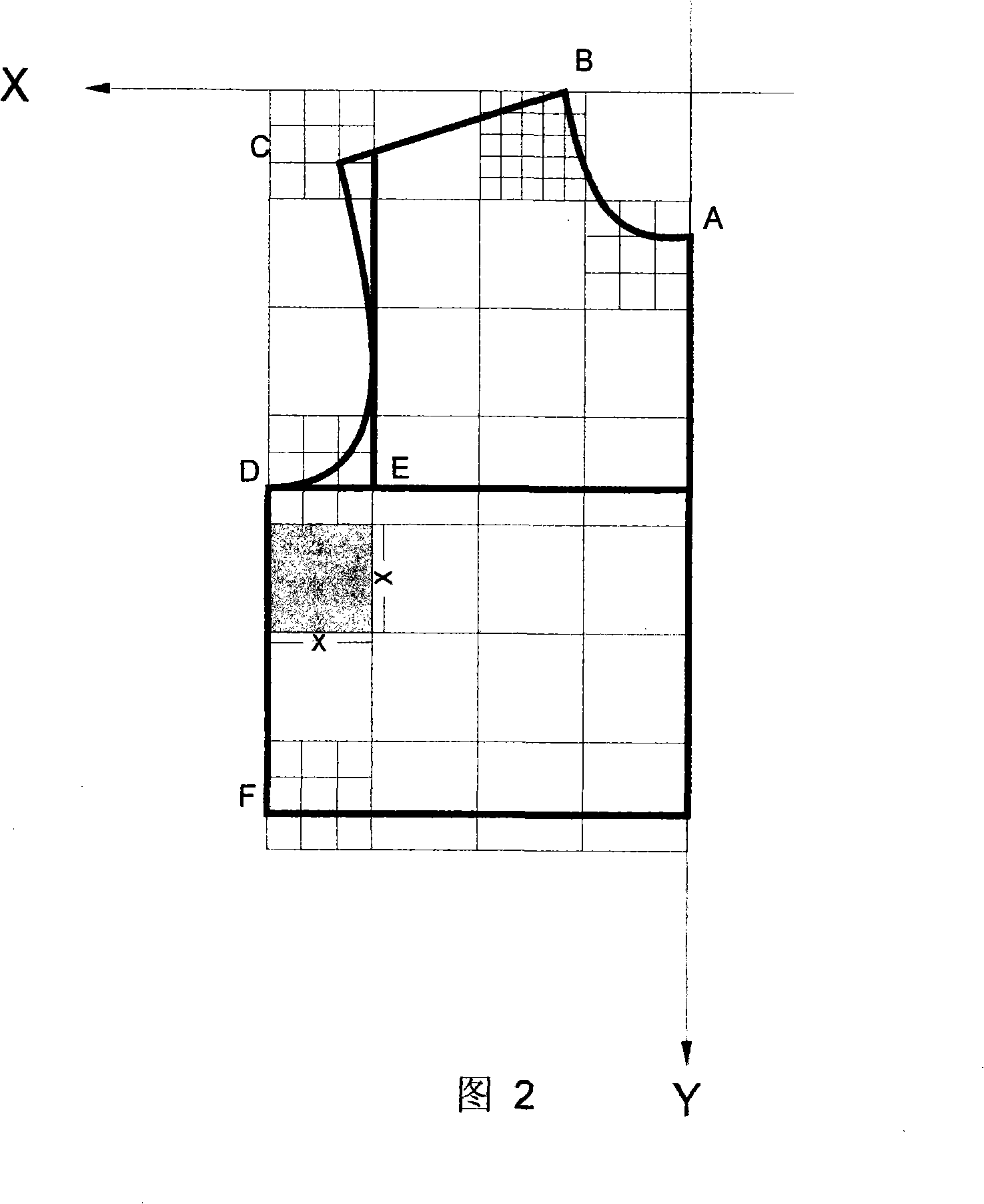

[0021] 2. Draw the basic pattern

[0022] According to the bust B=96cm in the finished garment data, draw the grid coordinates with 96 / 16=X as the unit, and according to the "coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com